Bent plate follow-up supporting device and using method thereof

A supporting and follow-up technology, applied in the field of sheet metal bending, can solve the problems of high manufacturing cost and precision requirements, complex connecting rod structure, and difficult installation, and achieve low installation difficulty, compact structure, and reduced floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

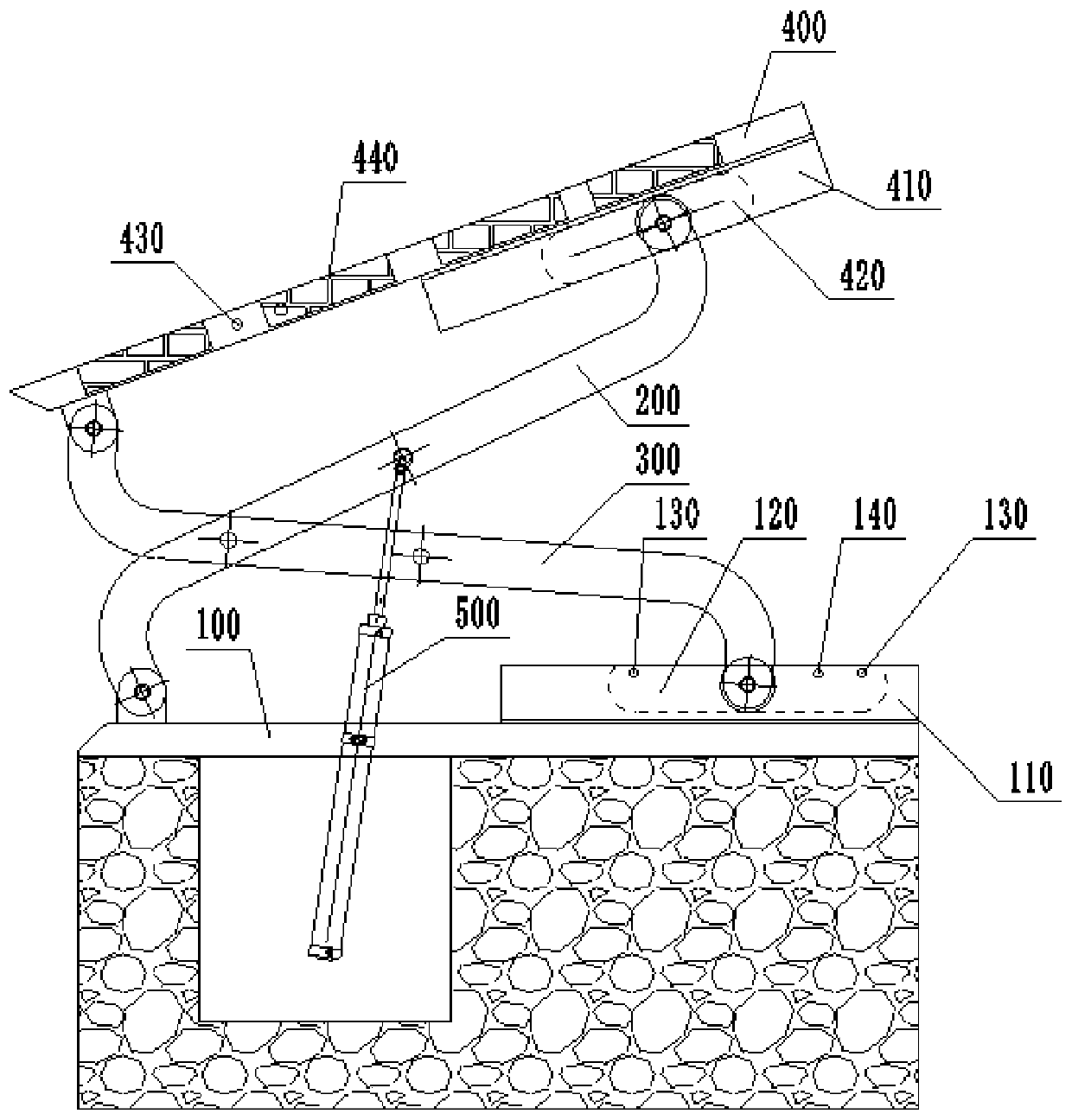

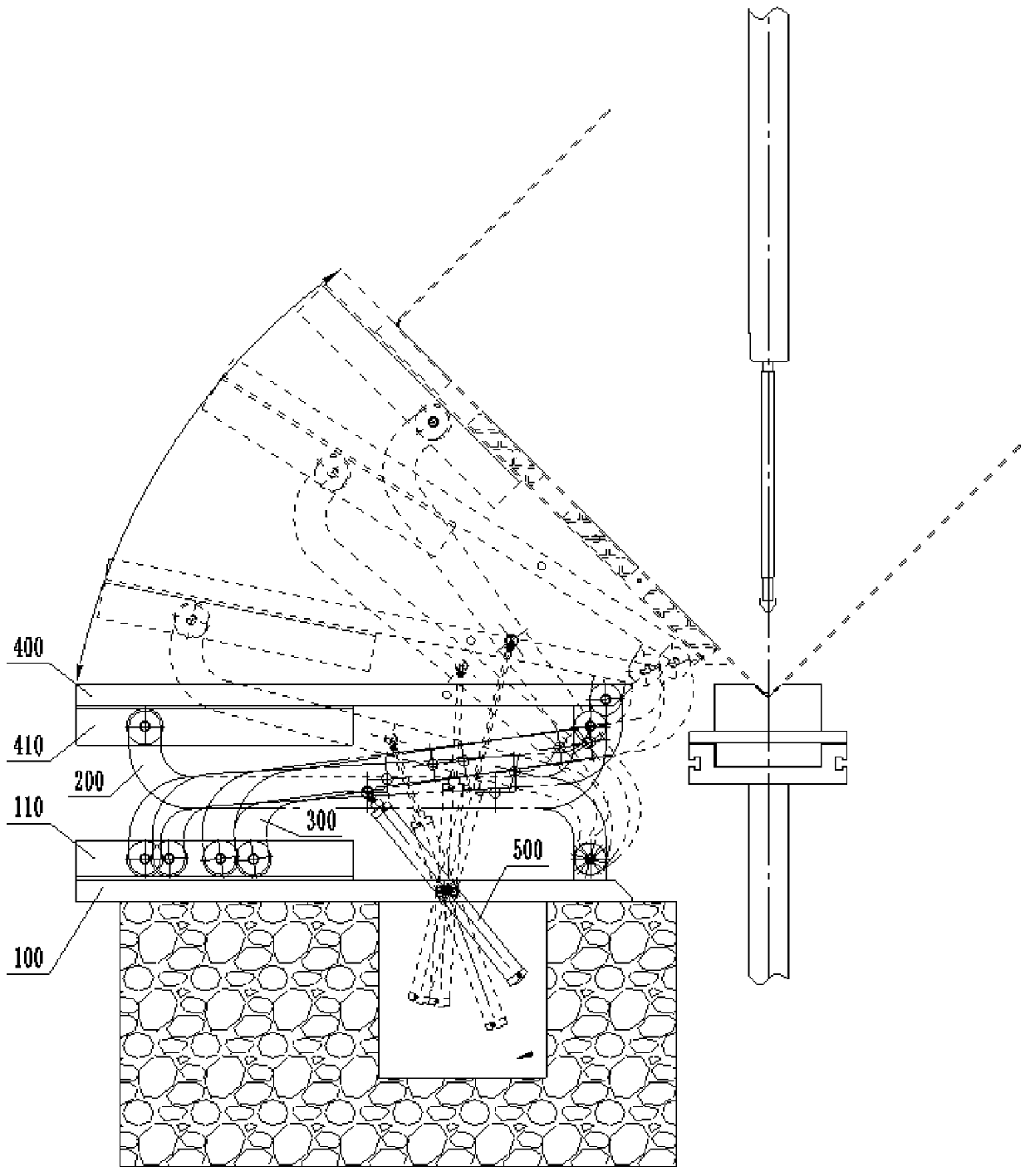

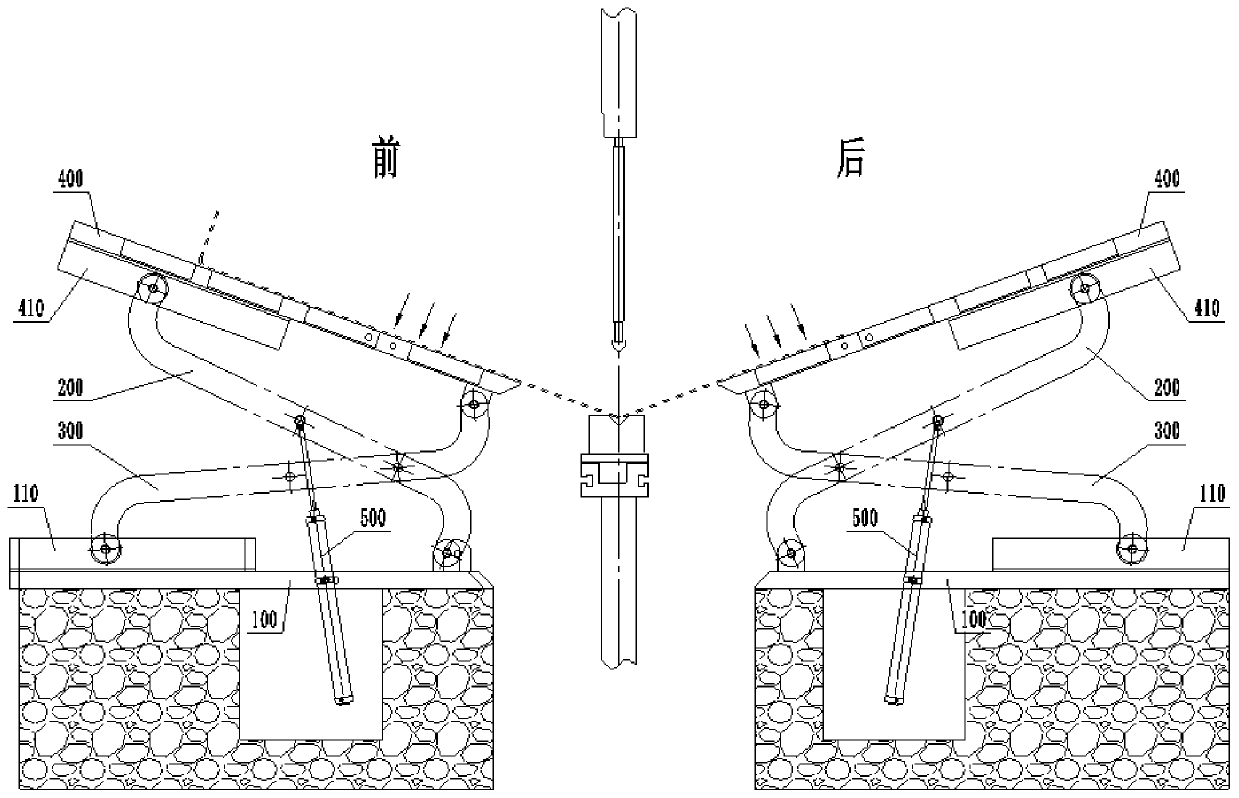

[0038] Such as figure 1 As shown, this embodiment provides a bending plate follow-up supporting device, which is mainly used in bending equipment such as bending machines, and supports during the bending process of the plate to ensure the bending accuracy of the plate and the bending accuracy of the plate. The surface quality of the material is especially important for large-size and thin-thick plates. The main body of the device is mainly composed of a base 100, an active support rod 200, a driven support rod 300, a supporting plate 400 and a driving cylinder 500, forming a connecting rod turning support structure.

[0039] Specifically, the base 100 is used as the installation base of the whole device, which can be directly used as the foundation on the ground, or fixedly installed on the ground, and the ground below it is provided with a pit, and the cylinder barrel of the drive cylinder 500 is hinged on the base 100, and the cylinder The lower half of the cylinder extends...

Embodiment 2

[0053] The above-mentioned embodiments have given the mechanical structure that can realize the bending follower of the sheet metal, but to complete the reliable follow-up action of the mechanical part, as well as other flipping actions, all must rely on precise control. On the basis of the mechanical structure of the follow-up support device, the plate follow-up support hydraulic system 600 is provided to control the expansion and contraction of the drive cylinder 500 to complete the turning action requirements. At the same time, it also solves the problems of extremely high requirements and poor reliability of the follow-up tracking material support control system of the existing bending machine.

[0054] Such as Figure 6 As shown, the bending plate supporting material hydraulic system 600 is composed of three parts: an oil tank 610 , a material supporting control part and an oil supply part 620 . Wherein, the oil inlet side of the oil supply part 620 is connected to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com