High-rise hoisting device for building construction

A technology for building construction and hoisting devices, which is used in hoisting devices, portable lifting devices, transportation and packaging, etc., can solve the problems of pipe fitting insertion, pipe fittings stuck at floor joints, and cannot be fed effectively, so as to reduce the difficulty. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

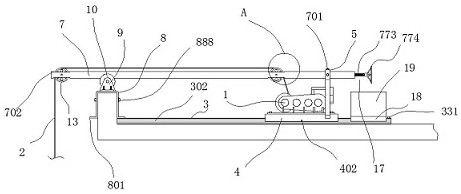

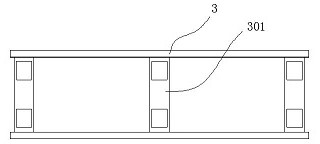

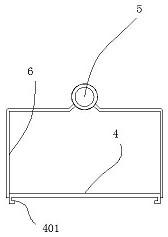

[0036]A high-rise hoisting device for building construction, including a hoist 1, and a steel cable 2 matching the hoist 1, and also includes two guide rails 3 arranged on the ground, and a connecting steel plate 301 is welded between the two guide rails 3, A guide groove 302 is processed on the outside of the guide rail 3, and a carrier plate 4 is assembled between the guide rails 3 on both sides, and the inner side of the carrier plate 4 is bent to form a guide bar 401 matching the guide groove 302, The bolts of the winch 1 are connected to the top of the carrier plate 4, and a set screw 402 is screwed into the outside of the carrier plate 4, and the set screw 402 is screwed into the guide groove 302. At this time The carrier plate 4 is fixed, and a ring body 5 is arranged above the carrier plate 4, and the bottom of the ring body 5 is welded with a frame 6, and the frame 6 and the carrier plate 4 are welded and fixed. , a support rod 7 is interspersed in the ring body 5, a ...

Embodiment 2

[0038] The base 8 is in the shape of a "several", and the bottom of the base 8 is bent outward to form a pressing plate part 801, which is pressed against the upper end of the guide rail 3; in the above structure, the base 8 realizes both The support of the pulley seat 9 is ensured, and the end of the guide rail 3 close to the wall is suppressed simultaneously, so that the installation of the guide rail 3 on the ground is more stable.

Embodiment 3

[0040] A first carrier plate 18 is also arranged between the guide rails 3 on both sides, and a counterweight box 19 is integrated at the upper end of the first carrier plate 18, and the counterweight box 19 is filled with counterweights such as water and sand; the first carrier plate The inner side of 18 has the first guide bar 188 that matches the guide groove 302; in the above structure, the position of the first carrier plate 18 can be moved, and can also be taken out, according to the needs of hoisting, we can fill in the counterweight box 19 Counterweight items are used to counterweight, increasing the stability of the guide rail 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com