Lithium-sulfur battery cathode material as well as preparation method thereof and application thereof

A technology for lithium-sulfur batteries and positive electrode materials, which is applied in the manufacture of battery electrodes, lithium batteries, and electrolyte batteries, etc., can solve problems such as energy density limitations, and achieve the effects of enhancing charge transfer, accelerating transfer and transmission, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

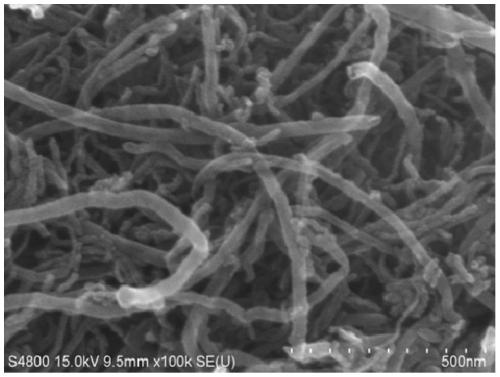

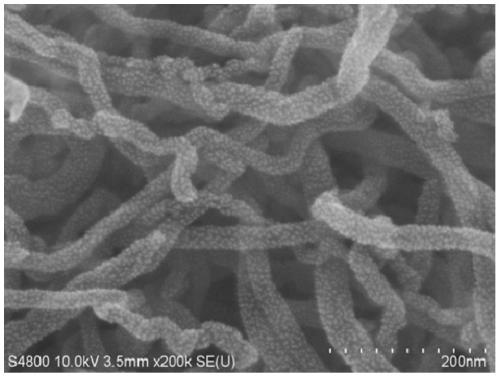

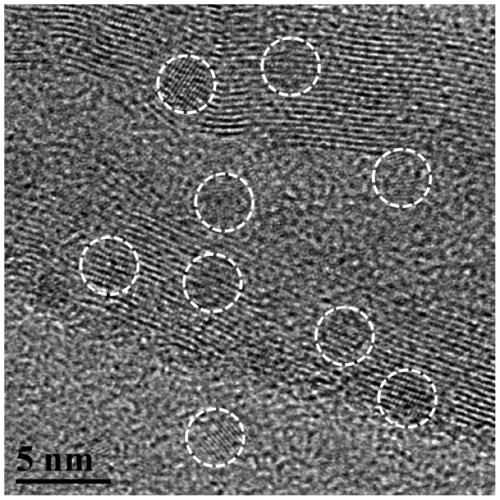

[0032] (1) Synthesis of zinc sulfide quantum dot-modified carboxylated multi-walled carbon nanotubes (ZnS-QDs / CNT): 0.1 g of carboxylated multi-walled carbon nanotubes with an outer diameter of 30-40 nm and an inner diameter of 10-20 nm The tubes were dispersed in 80mL deionized water, and then ultrasonicated for 20min to obtain an aqueous dispersion of carboxylated multi-walled carbon nanotubes; 0.068g of anhydrous zinc acetate and 0.312g of thioacetamide (TAA) were added to the resulting carboxylated multi-walled carbon nanotubes Stir in the water dispersion for 40min; transfer the stirred liquid to the reaction kettle, react at 50°C for 5h, then cool to room temperature, centrifuge, and then wash repeatedly with deionized water and ethanol, and finally in the 80°C Dry in a vacuum oven for 10 hours.

[0033] figure 1 For the SEM figure of the carboxylated multi-walled carbon nanotubes used in this embodiment, according to figure 1 It is shown that carboxylated multi-walled...

Embodiment 2

[0049] (1) Synthesis of zinc sulfide quantum dot-modified carboxylated multi-walled carbon nanotubes (ZnS-QDs / CNT): 0.15 g of carboxylated multi-walled carbon nanotubes with an outer diameter of 30-40 nm and an inner diameter of 10-20 nm Disperse in 80mL deionized water, and then sonicate for 20min to obtain an aqueous dispersion of carboxylated multi-walled carbon nanotubes; Stir in the dispersion for 40 minutes; transfer the stirred liquid to the reaction kettle, react at 50°C for 5h, then cool to room temperature, centrifuge, and then repeatedly wash with deionized water and ethanol, and finally dry in vacuum at 60°C Box drying for 10 hours.

[0050] (2) Preparation of ZnS-QDs / CNT / S: Take 0.2g of ZnS-QDs / CNT and 0.47g of sublimed sulfur and grind them in an agate mortar for 30min, then place the ground powder in an inert gas atmosphere in a glove box Put it into the reaction kettle, and finally place the reaction kettle in a blast drying oven at 165°C for 15 hours.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com