Method for realizing magnetic domain overturning by adopting piezoelectric shearing mode

A magnetic domain and piezoelectric technology, which is applied in the field of magnetic domain inversion using piezoelectric shearing mode, can solve problems such as difficulty in realizing magnetization inversion, and achieve the effects of simple structure, simple process and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

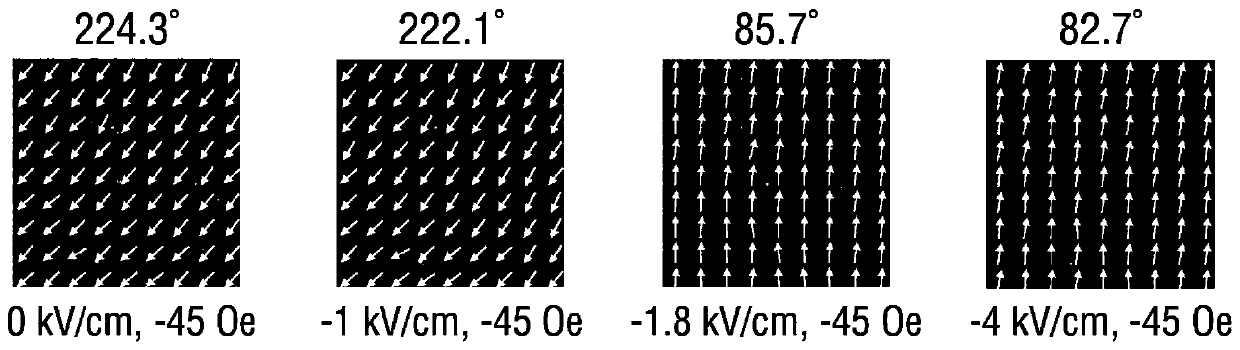

[0040] see figure 1 , figure 2 As shown, the purpose of the present invention is to provide a method of using piezoelectric shear mode to realize magnetic domain switching, including the preparation of magnetoelectric heterojunction and the shear strain induced by electric field and DC bias magnetic field acting together on the magnetoelectric Heterojunction process.

[0041] (1) The preparation process of the magnetoelectric heterojunction, the specific implementation process is:

[0042] A. Clean the commercial piezoelectric single crystal substrate PMN-PT (011) with acetone, alcohol, and deionized water in sequence, and dry the surface with nitrogen.

[0043] B. Fix the cleaned substrate on the tray and place it in the magnetron sputtering chamber, adjust the parameters according to the correct experimental process, and then go through the processes of vacuuming, filling with argon, and bombarding the target with argon ions Process for proper FeCoSiB magnetic film prepa...

Embodiment 2

[0056] A method for realizing magnetic domain inversion by using a piezoelectric shear mode provided by the present invention can also be realized through the following preparation of a magnetoelectric heterojunction and shear strain induced by an electric field.

[0057](1) The preparation process of the magnetoelectric heterojunction, the specific implementation process is:

[0058] A. Clean the commercial piezoelectric single crystal substrate PZN-PT (011) with acetone, alcohol, and deionized water in sequence, and dry the surface with nitrogen.

[0059] B. Fix the cleaned substrate on the tray and place it in the magnetron sputtering chamber, adjust the parameters according to the correct experimental process, and then go through the processes of vacuuming, filling with argon, and bombarding the target with argon ions Procedure for proper CoFeB magnetic film preparation.

[0060] C. Repeat step B to prepare a 20nm copper metal electrode on the other side of the PZN-PT(011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com