Solid-state relay power assembly and production method

A technology of solid state relays and power components, applied in the direction of electric solid state devices, relays, semiconductor devices, etc., can solve problems such as stress breakdown, low production efficiency, and prone to failure, so as to eliminate bending stress, improve production efficiency, and avoid The effect of thermal breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

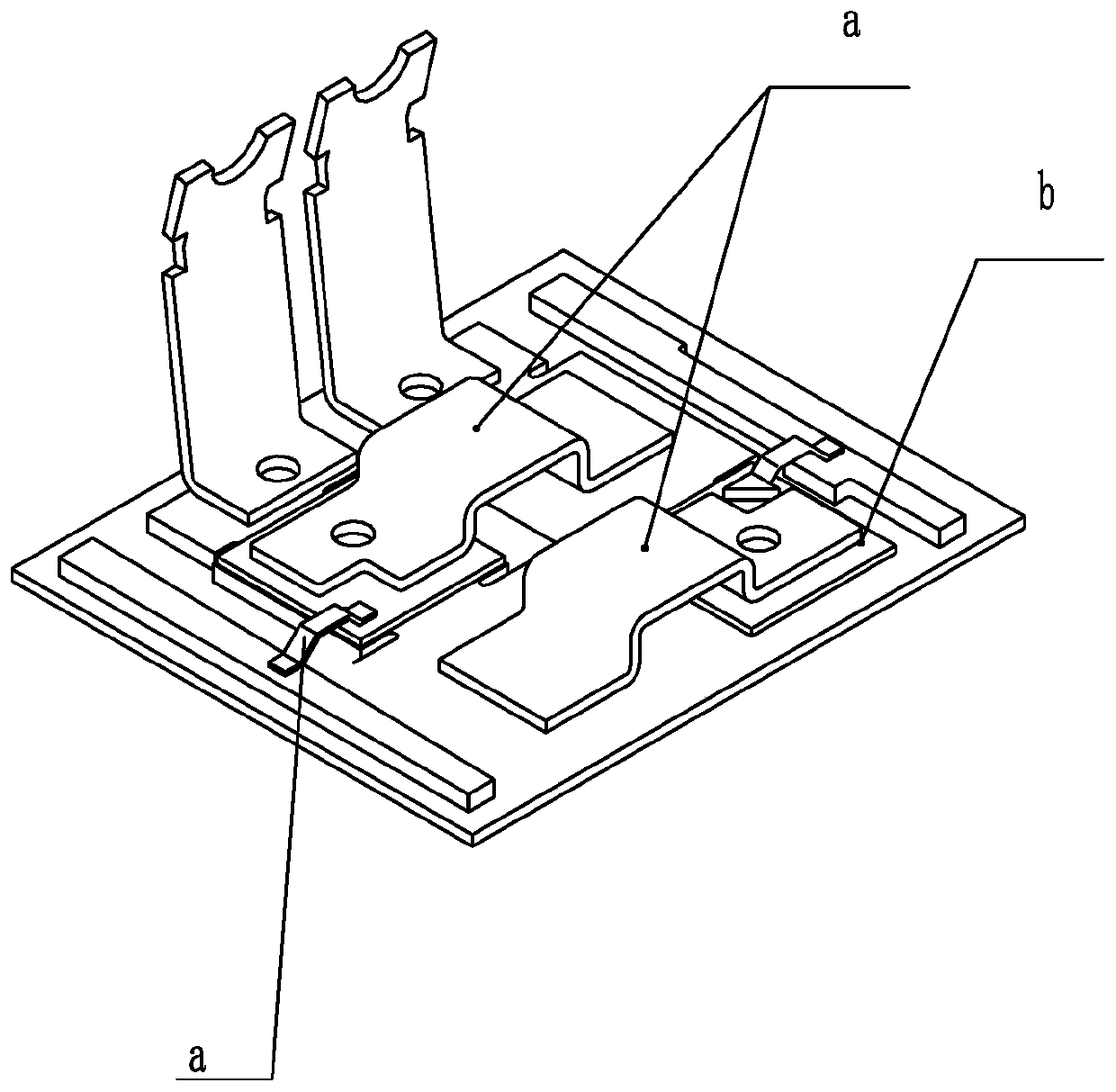

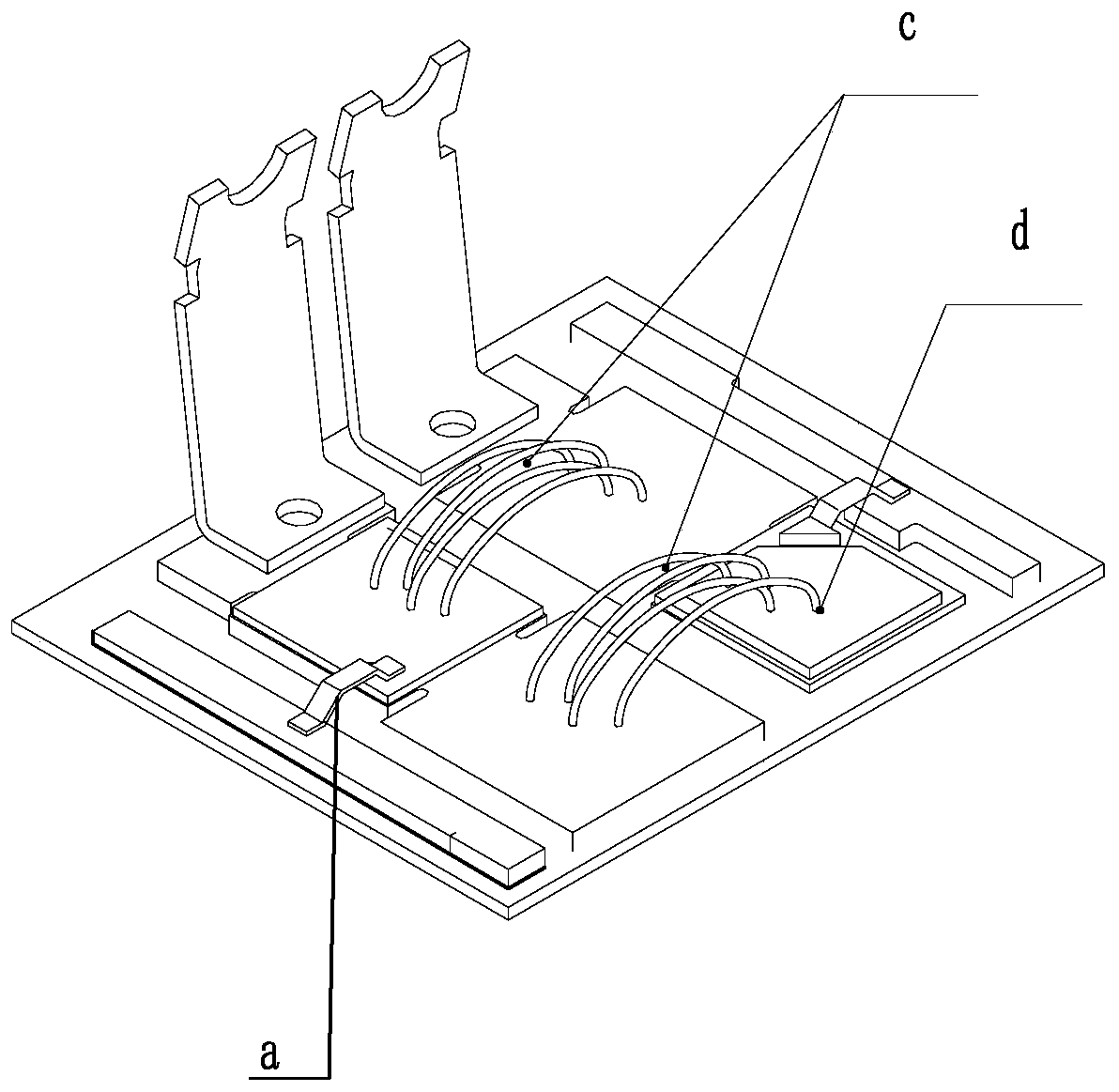

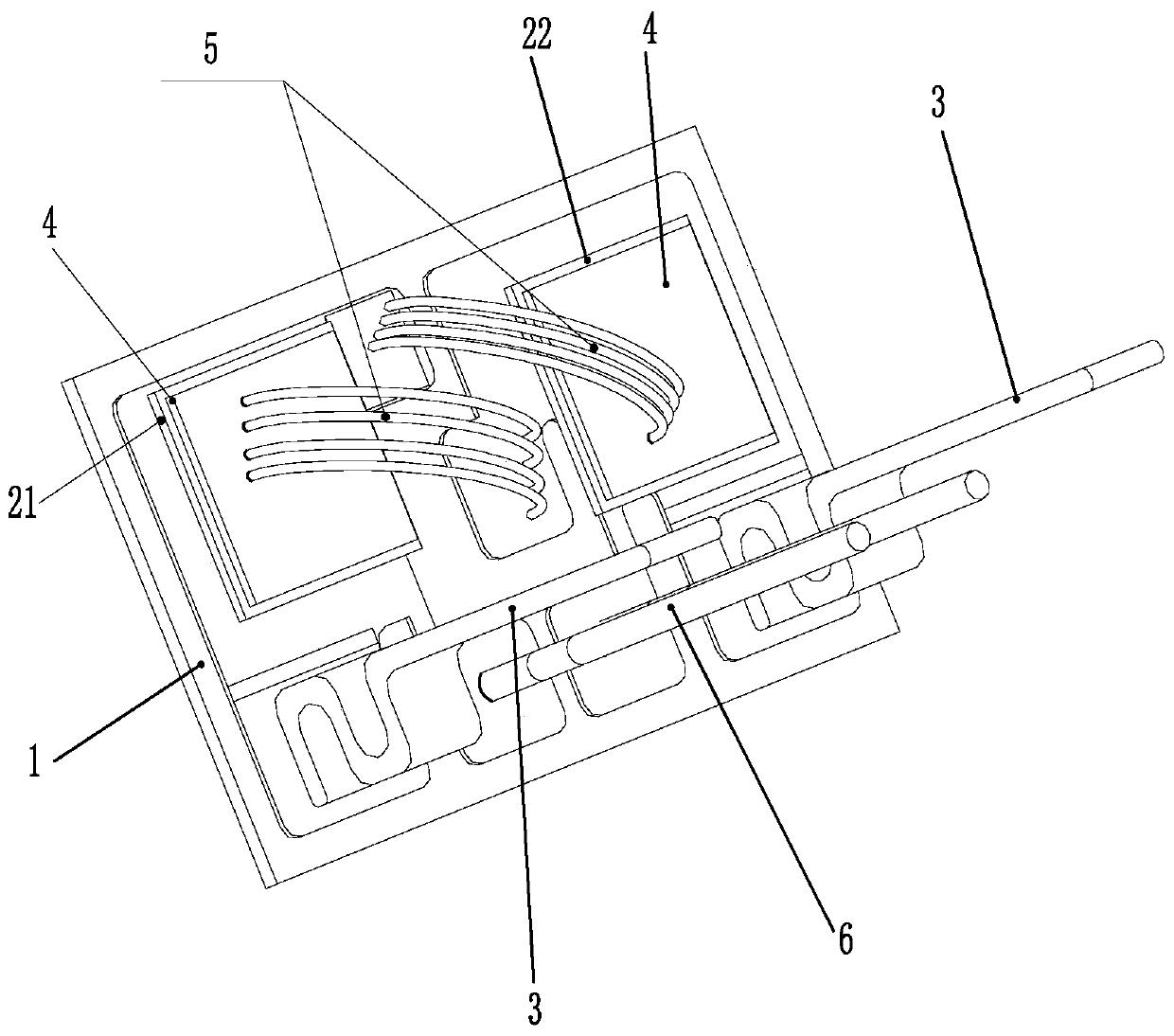

[0034] Example: see image 3 and Figure 4 , a solid state relay power component, including a substrate 1 and a power chip on it, the power chip is composed of a first chip 21 and a second chip 22, the two power chips are flip-chip arranged on the substrate 1, and each power chip leads to a main The electrodes 3 are respectively welded with a conductive sheet 4 on the upper surfaces of the two power chips, and the conductive sheet 4 of one power chip is connected to the corresponding electrode of the other power chip through a lead wire 5 to realize the electrical connection between the power chips, specifically the first chip 21 The conductive sheet 4 of the anode is connected to the lead-out copper foil of the cathode of the second chip 22 through the lead wire 5. This copper foil is the preset covering copper material on the substrate, and the conductive sheet 4 of the anode of the second chip 22 is connected to the first chip 21 through the lead wire 5. The lead-out coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com