Device and method for relieving blockage of rotary air pre-heater by means of hot primary air preheating and heat storage elements

A rotary air preheater technology, applied in combustion methods, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as increased blockage, increased pressure difference between the inlet and outlet of the air preheater, and increased fan power consumption. Achieve the effect of convenient installation and construction, reduce the degree of clogging, and improve the effect of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

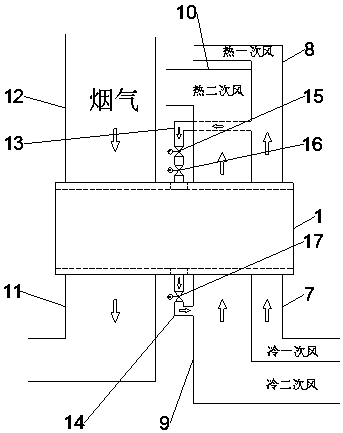

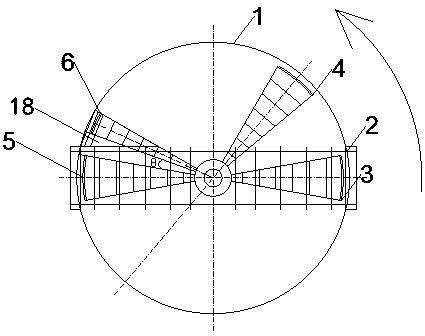

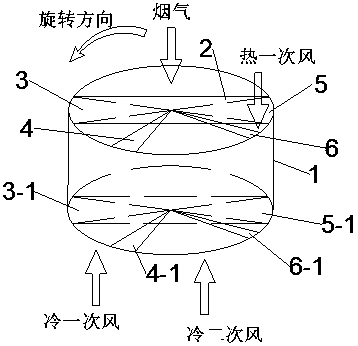

[0018] see Figure 1 to Figure 3 , in this embodiment, a device for relieving blockage of a rotary air preheater by hot-air preheating heat storage elements, including a rotary air preheater 1, a cold primary air duct 7, a hot primary air duct 8, and a cold secondary air Road 9, hot secondary air duct 10, flue gas outlet duct 11 and flue gas inlet duct 12, the flue gas inlet duct 12 and flue gas outlet duct 11 are connected to the flue gas inlet and the flue gas outlet duct 1 of the rotary air preheater 1 respectively The flue gas outlet is connected, the cold primary air channel 7 and the hot primary air channel 8 are respectively connected with the primary air inlet and the primary air outlet of the rotary air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com