Capping beam mounting method for mutual constraint of adjacent pier columns in prefabricated bridge

A prefabricated assembly and installation method technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as difficulty in ensuring the degree of cooperation between pier columns and cover beams, inability to install cover beams in position, and increase in construction costs. The structure is firm and reliable, the construction process is fast, and the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

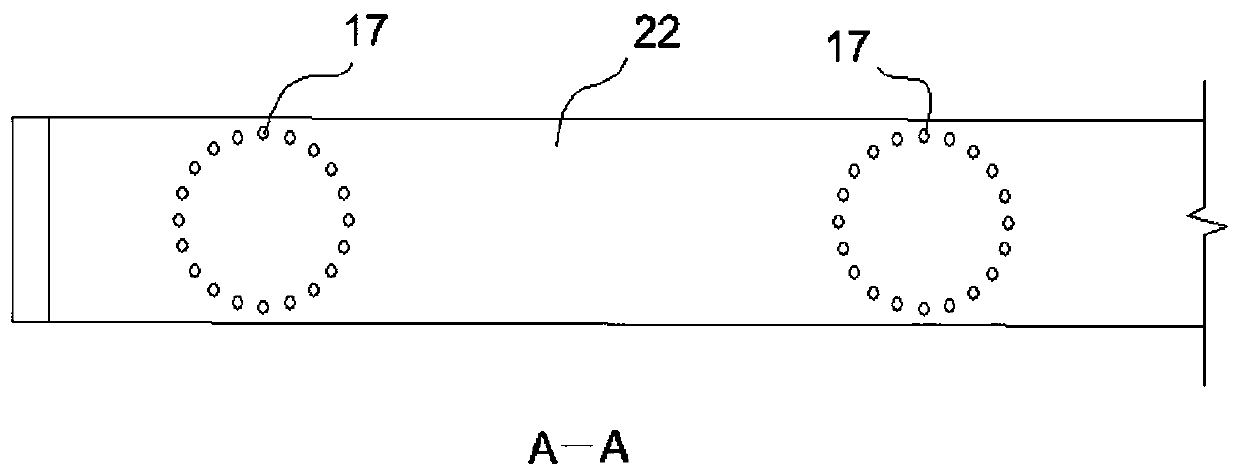

[0046] see figure 1 and figure 2 , the pier column in this embodiment is a prefabricated pier column 2, and the top of the prefabricated pier column 2 has a protruding pier column embedded steel bar 15, and the pier column pre-embedded steel bar 15 is evenly distributed in a circular shape on the top of the prefabricated pier column 2, Form a pier column pre-embedded steel bar ring with a radius of r; the cover beam is a prefabricated cover beam 22, and the two ends of the prefabricated cover beam 22 are pre-embedded with a cover beam pre-embedded sleeve 19, and the cover beam pre-embedded sleeve 19 can use steel corrugation The corrugated pipe structure can further enhance the bonding firmness between the pre-embedded steel bar 15 of the pier column and the pre-embedded sleeve 19 of the cover beam. On the top of the prefabricated cover beam 22, there is a vertical grouting channel 17 and the steel bar connection sleeve. 19 are connected; the prefabricated cover beam pre-emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com