Low-weight food packaging paper added with nanocellulose and manufacturing method thereof

A technology of food wrapping paper and nanocellulose, which is applied in the directions of wrapping paper, wrapping paper, pulp beating method, etc., can solve the problems of environmental degradation impact, hidden danger of food migration, etc., to improve fine control, improve user experience, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

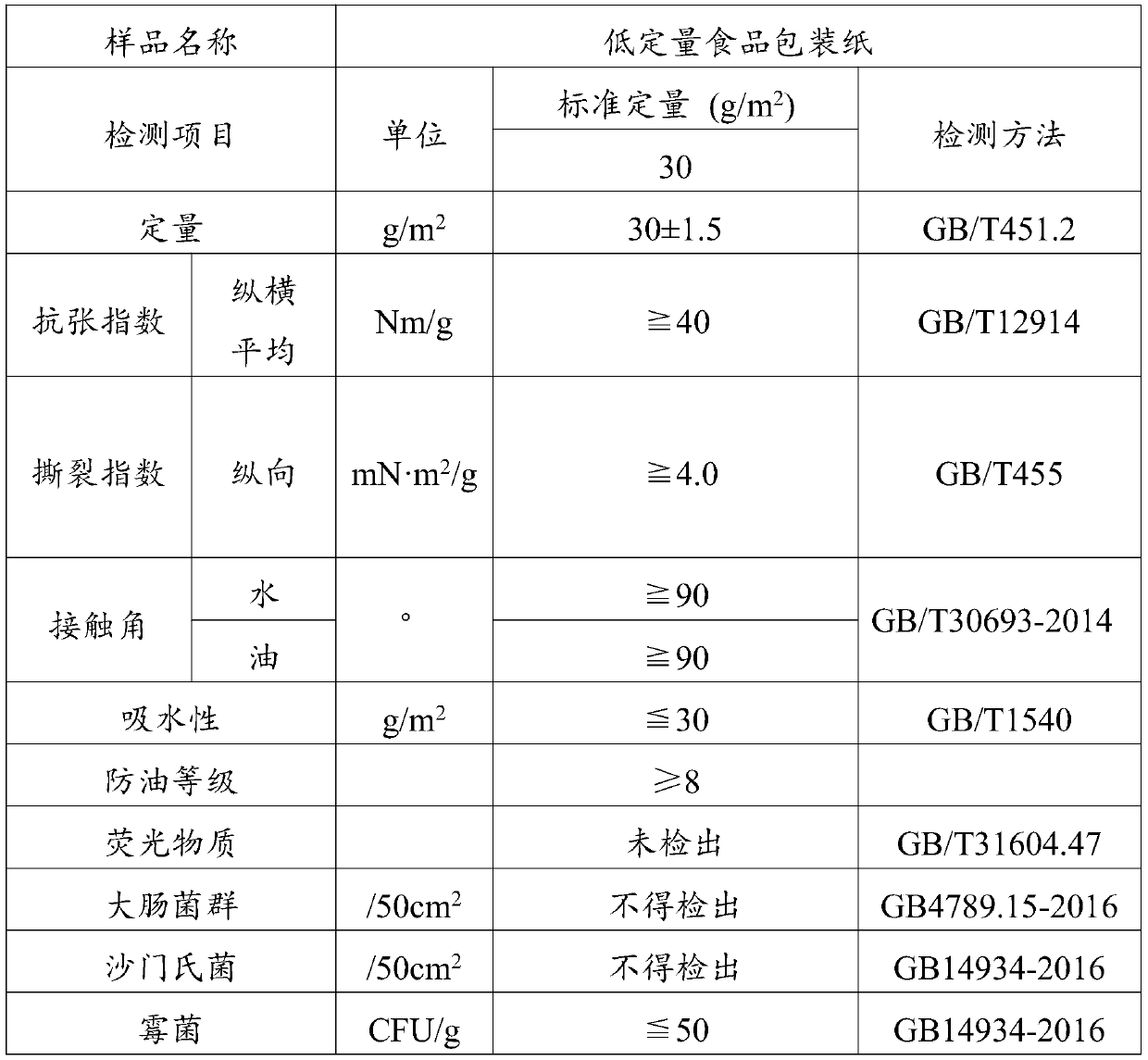

Image

Examples

Embodiment 1

[0044] A kind of manufacture method of the low quantitative food wrapping paper that adds nanocellulose, is characterized in that, comprises the following steps:

[0045]1) Using imported kraft softwood pulp without fluorescent whitening agent, imported kraft hardwood pulp, and domestic bleached or unbleached aseptic bamboo pulp as fiber pulp, it is obtained after hydropulping and long-fiber viscous beating A slurry with a concentration of 5.5% and an average fiber number length of more than 1.5mm; said step 1) the beating degree is controlled at 70°SR, and the wet weight is required to be greater than 4.5g;

[0046] 2) Add nanocellulose to the slurry mixing tank, and add wet strength agent, dry strength agent and antibacterial agent, and carry out slurry mixing with the slurry in step 1); In the step 2), the weight ratio of each component is pulp: Nanocellulose: wet strength agent: dry strength agent: fungicide=100:2.5:1.2:0.6:0.015.

[0047] 3) Purify and screen after pulpi...

Embodiment 2

[0054] A kind of manufacture method of the low quantitative food wrapping paper that adds nanocellulose, is characterized in that, comprises the following steps:

[0055] 1) Using imported kraft softwood pulp without fluorescent whitening agent, imported kraft hardwood pulp, and domestic bleached or unbleached aseptic bamboo pulp as fiber pulp, it is obtained after hydropulping and long-fiber viscous beating A slurry with a concentration of 7.0% and an average fiber number length of more than 1.5mm; said step 1) the beating degree is controlled at 60°SR, and the wet weight is required to be greater than 4.5g;

[0056] 2) Add nanocellulose to the slurry mixing tank, and add wet strength agent, dry strength agent and antibacterial agent, and carry out slurry mixing with the slurry in step 1); In the step 2), the weight ratio of each component is pulp: Nanocellulose: wet strength agent: dry strength agent: fungicide=100:4.0:0.8:1.0:0.01.

[0057] 3) Purify and screen after pulpi...

Embodiment 3

[0064] A kind of manufacture method of the low quantitative food wrapping paper that adds nanocellulose, is characterized in that, comprises the following steps:

[0065] 1) Using imported kraft softwood pulp without fluorescent whitening agent, imported kraft hardwood pulp, and domestic bleached or unbleached aseptic bamboo pulp as fiber pulp, it is obtained after hydropulping and long-fiber viscous beating A slurry with a concentration of 6.5% and an average fiber number length of more than 1.5mm; said step 1) the beating degree is controlled at 65°SR, and the wet weight is required to be greater than 4.5g;

[0066] 2) Add nanocellulose to the slurry mixing tank, and add wet strength agent, dry strength agent and antibacterial agent, and carry out slurry mixing with the slurry in step 1); In the step 2), the weight ratio of each component is pulp: Nanocellulose: wet strength agent: dry strength agent: fungicide=100:3.0:1.0:0.8:0.013.

[0067] 3) Purify and screen after pulp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com