A kind of non-oriented electrical steel for frequency conversion air conditioner and its manufacturing method

A technology of oriented electrical steel and frequency conversion air conditioner, which is applied in the direction of manufacturing tools, improvement of process efficiency, furnace, etc., to achieve low iron loss, save resources and energy, and reduce volume

Active Publication Date: 2021-04-09

新余钢铁股份有限公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the existing documents, no thickness of 0.25-0.30mm, iron loss P 1.5 / 50 ≤2.15W / kg non-oriented electrical steel and its manufacturing method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 6

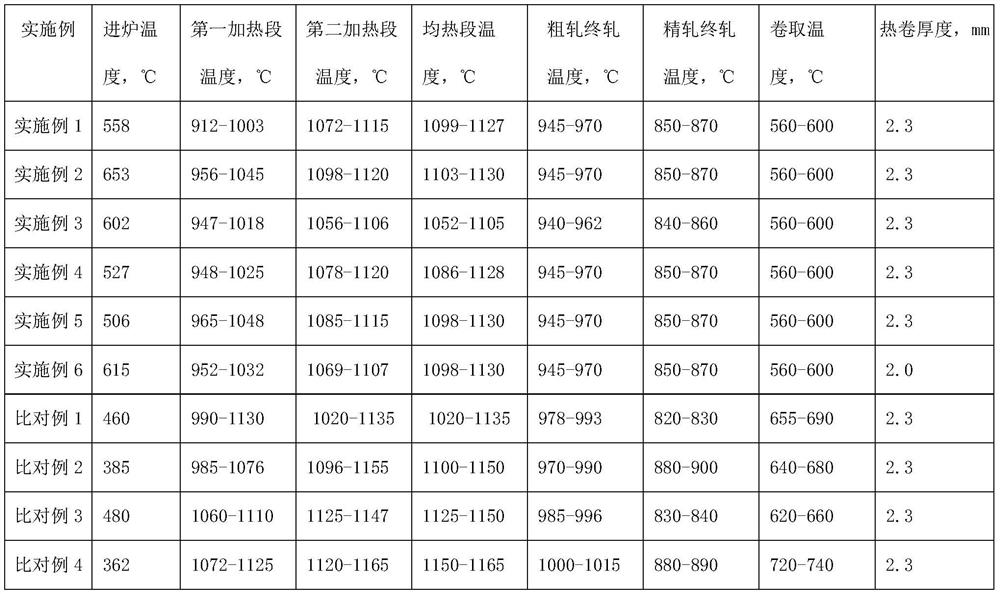

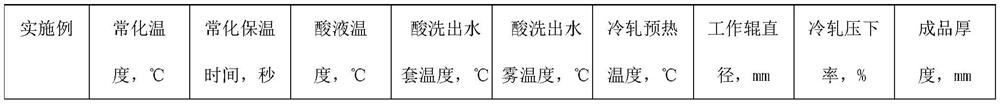

[0037]A variable-conversion air conditioner is used without regenerative electrical steel, including the following mass percent chemical composition, shown in Table 1, and the remaining amount of the remaining amount of Fe and inevitable residual elements in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a non-oriented electrical steel for frequency conversion air conditioner and its manufacturing method. , [Si]2.80%‑3.4%, [Al]0.20%‑1.20%, [N]≤0.0025%, [Sn]0.01‑0.10%, the balance is Fe and unavoidable residual elements; manufacturing method: steelmaking , continuous casting, heating, hot rolling, normalization, pickling, cold rolling, annealing, cooling and coating; the thickness of the product of the present invention is 0.25-0.30mm, and the iron loss of the product is P 1.5 / 50 ≤2.15W / kg, magnetic polarization J 5000 ≥1.65T, fast magnetization speed, low iron loss, suitable for the working conditions of inverter air conditioner compressors, can reduce the volume and weight of inverter air conditioners, reduce power consumption, and save resources and energy.

Description

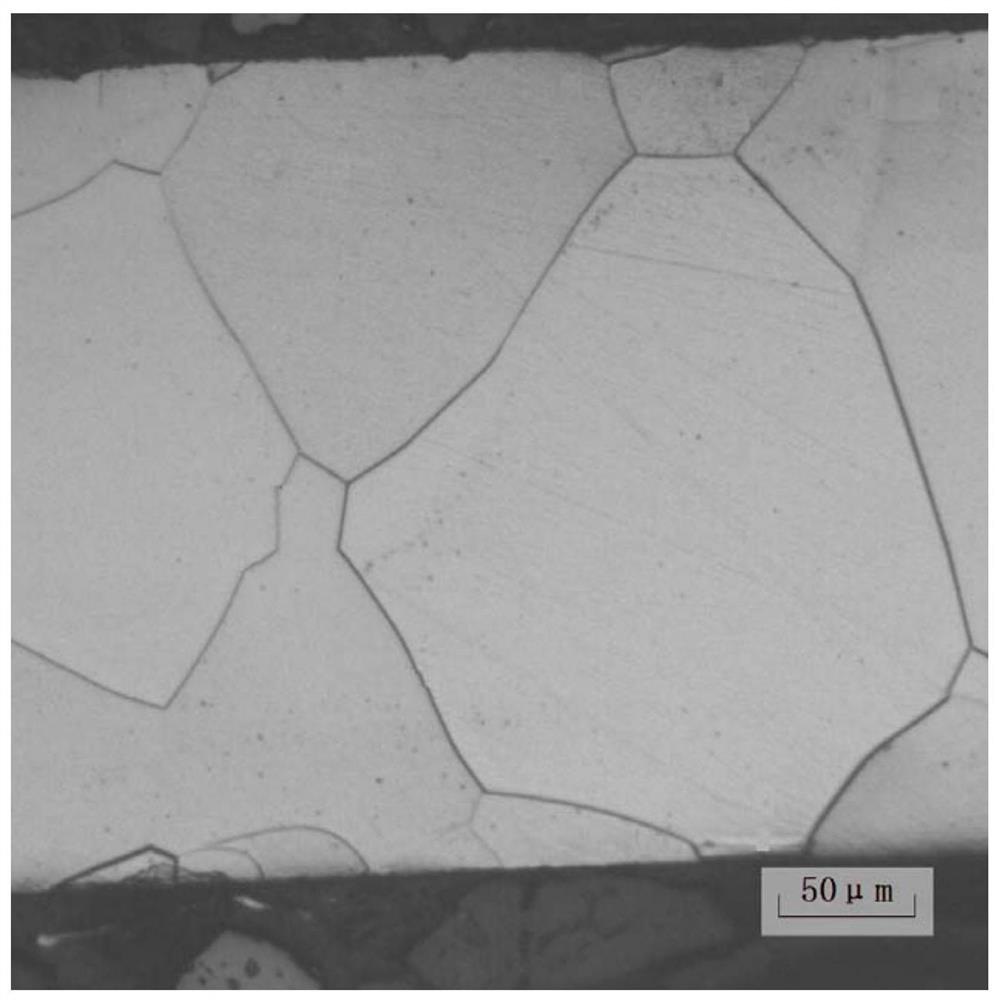

Technical field[0001]The present invention belongs to the field of alloy smelting, and more particularly to a variable-conversion air conditioner without oriented electrical steel and a manufacturing method thereof.Background technique[0002]No longer taking the process of long, process complex, and has more influencing factors of product quality. In particular, the compressor of the inverter air conditioner is frequently used, and the frequency of use of the process is large, the working conditions are complex, and the electromagnetic properties and thickness of the non-replacement electrician steel is high.[0003]The application number disclosed on July 20, 2011 is 2011110008574.x "a method for manufacturing cold rolling without retroffall air conditioner", the main chemical component [Si] 0.5% -1.0%, [Al] 0.1-0.5 %, Product iron damage P10 / 400≤25W / kg, P10 / 1000≤ 1110 W / kg, its annealing temperature is low temperature of 660-690 ° C, and does not remove carbon. The finished carbo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C33/04C21D1/26C21D1/76C21D6/00C21D8/12C21D9/52C22C38/02C22C38/04C22C38/06C22C38/18

CPCC21D1/26C21D1/76C21D6/005C21D6/008C21D8/1216C21D9/52C22C33/04C22C38/001C22C38/002C22C38/004C22C38/008C22C38/02C22C38/04C22C38/06C22C38/18Y02P10/20

Inventor 冷烨旻冯小明冷光荣裴伟龚红根余小琴刘船行张邹华黄有财徐细华管兴伟黄素中万伟严政李娜李员妹

Owner 新余钢铁股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com