Method and system for producing needle coke raw material oil by performing reduced pressure distillation on catalytic slurry oil to remove aromatic hydrocarbon oil solids

A technology of catalytic oil slurry and needle coke, which is only applied in the direction of multi-stage series refining process, can solve the problems of slow industrialization of oil-based needle coke, and achieve the effect of increasing the desolidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

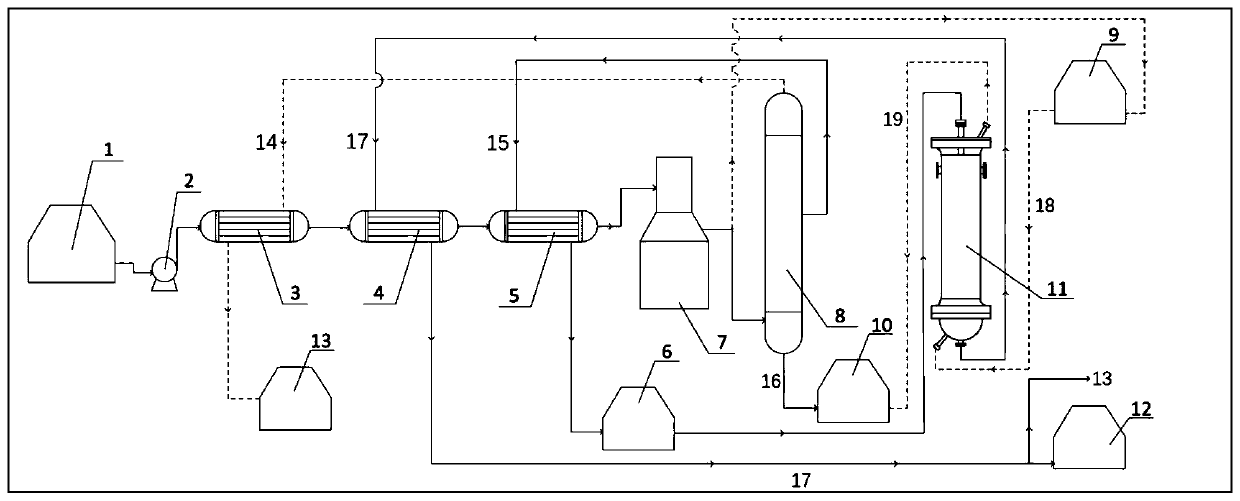

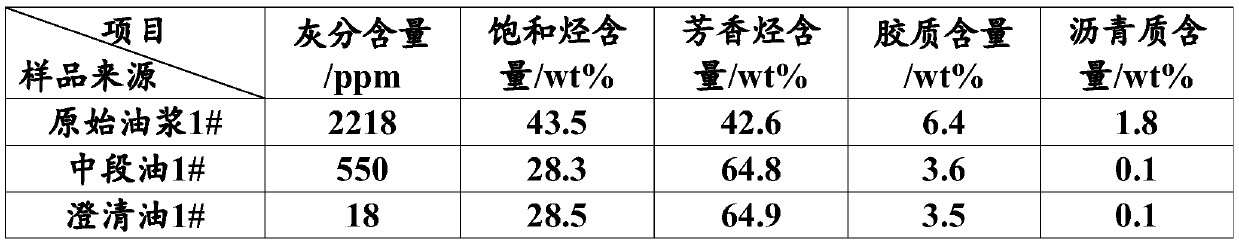

[0063] In the S1 step, the original oil slurry stored in the oil slurry storage tank 1 (this oil slurry will come from a refinery of Sinopec in the future, referred to as oil slurry SLO in this embodiment) is extracted from the oil slurry pump 2 of the storage tank. The oil slurry storage tank 1 enters the upper stage oil heat exchanger 3 for heat exchange and preheating, and the upper stage oil whose temperature drops after heat exchange is transported to the light oil storage tank 13; after the first heat exchange, the original oil slurry enters the clarified oil heat exchanger 4 for Secondary heat exchange, after the temperature continues to rise, it enters the middle oil heat exchanger 5 for three times of heat exchange, making full use of the waste heat of vacuum distillation and liquid-solid separator, and the catalytic oil slurry after heat exchange enters the S2 step. The middle section oil enters the middle section oil surge tank 6. At the same time, the original oil ...

Embodiment 2

[0072] Step S1, step S2, and step S3 in this embodiment 2 are the same as those in embodiment 1, and the only difference lies in step S4.

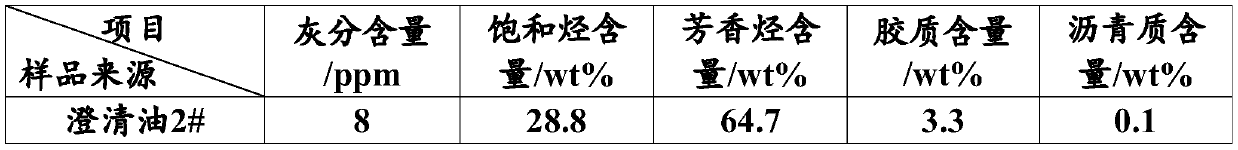

[0073] In the S4 step, during the treatment of the liquid-solid separator, different from Example 1, the externally connected high-voltage power supply applies a DC high voltage of up to 35KV to the liquid-solid separator, and generates a maximum of about 9.2× in the separator. 10 5 With a strong electric field of V / m, under the action of a strong gradient electric field force, the solid particles in the aromatic oil flowing through the packed bed of the separator will be moved by force and removed from it, and the solid ash content of the desolidified clarified oil will be reduced to below 10ppm. Other operating parameters are the same as step S4 in Example 1. The decant oil product is sampled at the finished product storage tank 12 or the measuring line of the needle coke production line to obtain decant oil sample 2#.

[0074] The ash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com