A kind of injectable composite antibacterial hydrogel and preparation method thereof

A composite antibacterial and hydrogel technology, applied in the field of hydrogel, can solve the problems of short antibacterial validity period, unstable antibacterial effect, and easy leakage of antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of an injectable composite antibacterial hydrogel, comprising the following steps:

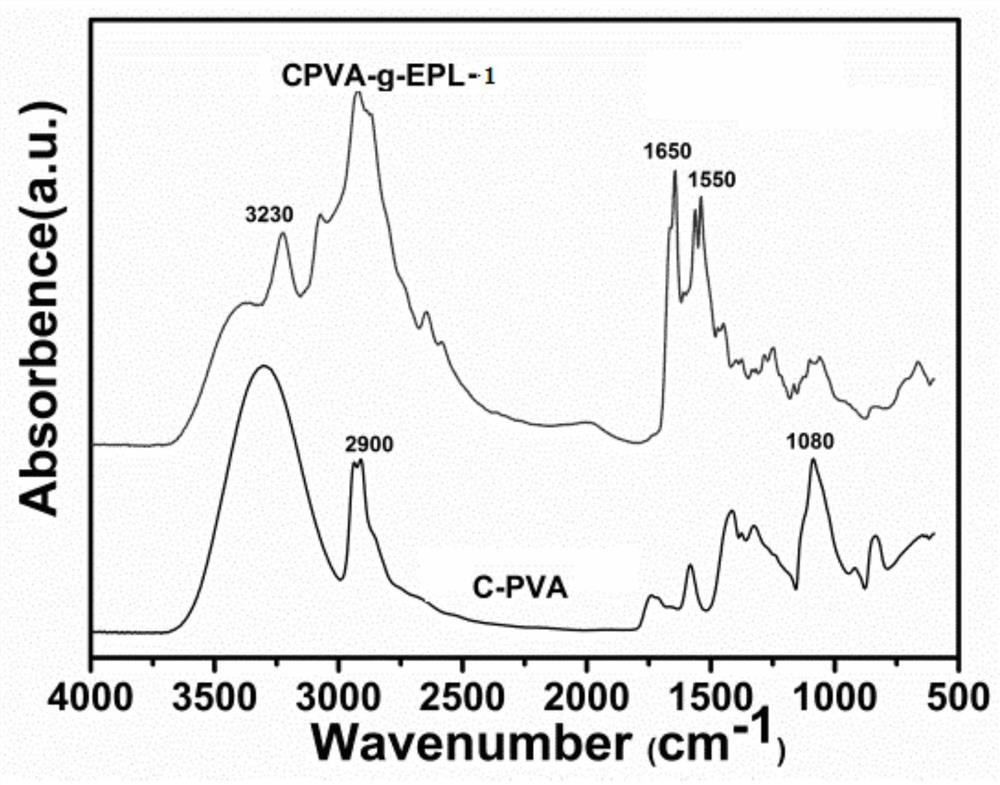

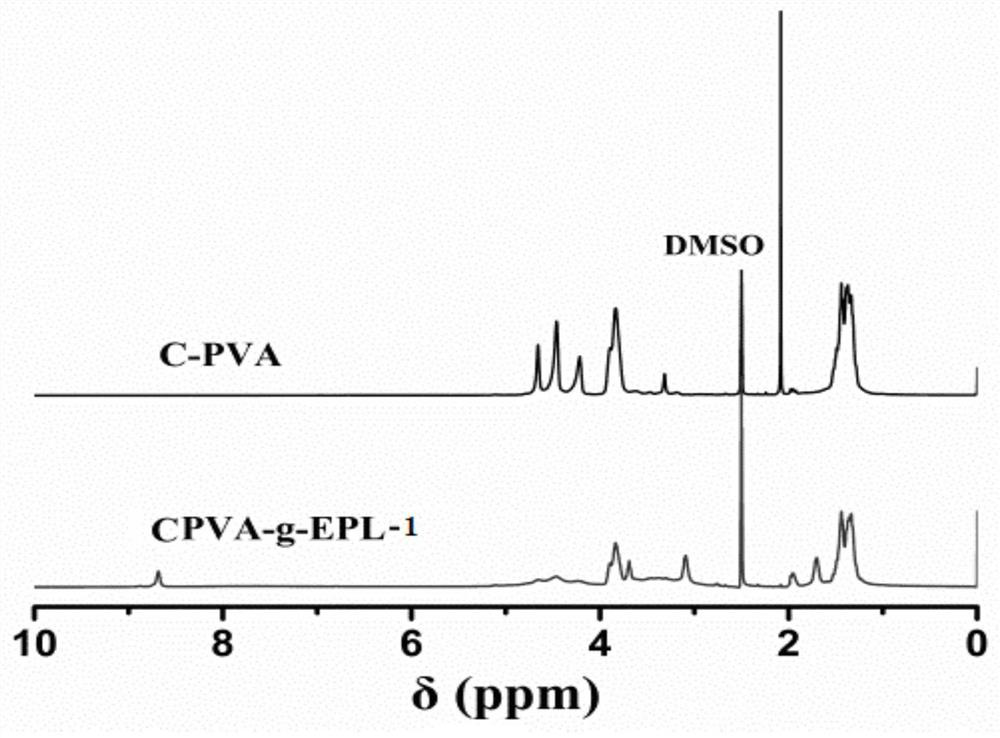

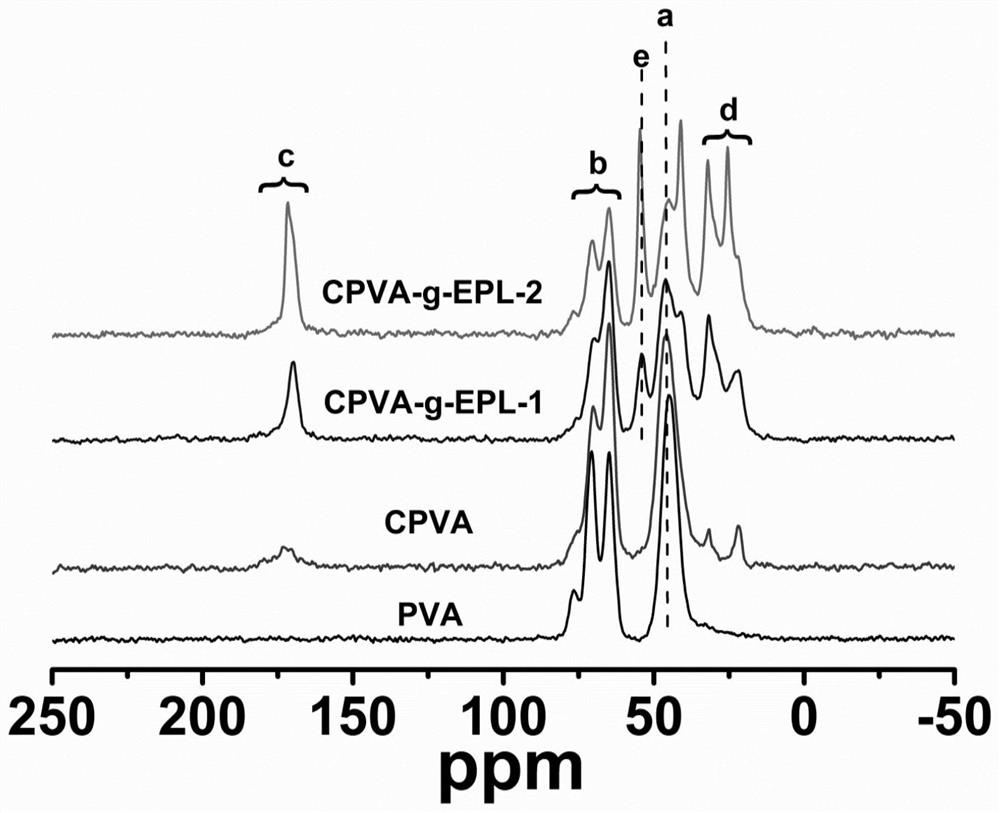

[0023] In the presence of a catalyst, the carboxylated polyvinyl alcohol (C-PVA) solution is adjusted to a pH value of 3 to 4 and then reacted with ε-polylysine (EPL) to obtain an amino-modified polyvinyl alcohol solution (CPVA-g- EPL);

[0024] Blending the chitosan (CS) solution, the dextran formaldehyde solution and the amino-modified polyvinyl alcohol solution to obtain an injectable composite antibacterial hydrogel;

[0025] The mass ratio of amino-modified polyvinyl alcohol, chitosan and glucan is 4-1:1:0.05-0.5.

[0026] The method provided by the invention adopts amino-modified polyvinyl alcohol with antibacterial function, and after blending with chitosan, utilizes the amino groups on the molecular chains of the two and the aldehyde groups on the molecular chains of dextran to form a dynamic Schiff base bond , so that the prepared h...

Embodiment 1

[0043] Take 20mL of refined vinyl acetate and add it to 40mL of methanol, pass nitrogen gas to remove oxygen for 30min, then add 0.02gAIBN, 3mL acrylic acid, react at 65°C for 8h, the product is precipitated in deionized water, and the product is named P(VAc-co -AA); Then configuration mass percent is 25% P (VAc-co-AA) methanol solution, add an appropriate amount of 1mol / L sodium hydroxide methanol solution at normal temperature, make the mass of NaOH and P (VAc-co-AA) When the ratio reaches 0.02, after mixing evenly, carry out alcoholysis reaction in a constant temperature water bath at 50°C for 30 minutes to obtain a colloidal product, heat and dissolve the colloidal product with deionized water, filter to remove insoluble impurities, cool to room temperature, and use methanol as a precipitant to precipitate 3 times , filtered, and dried to obtain carboxylated polyvinyl alcohol (C-PVA).

[0044] Add 10mL of deionized water to a 100mL two-necked flask, add 1g of C-PVA, add an...

Embodiment 2

[0053] The experimental steps for preparing carboxylated polyvinyl alcohol (C-PVA), amino acid modified polyvinyl alcohol (CPVA-g-EPL-1) and dextran formaldehyde (ODEX) are the same as in Example 1.

[0054] Take 0.7mL CPVA-g-EPL-1 solution with a mass percentage of 10%, add 1.4mL chitosan solution with a mass percentage of 2.5% and 200μL ODEX solution with a mass percentage of 6%, and mix well at room temperature to prepare a hydrogel Glue, the product number is S2. Antibacterial test results show that the antibacterial rate of S2 against Escherichia coli is 99.96%, and the antibacterial rate against Staphylococcus aureus is 99.98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com