Ortho-aminobenzoic acid derivative and application thereof

An anthranilic acid and derivative technology, which is applied in the directions of drug combination, cosmetic preparations, cosmetics, etc., can solve the problems of inability to completely remove dandruff, unsatisfactory effect, unsatisfactory effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

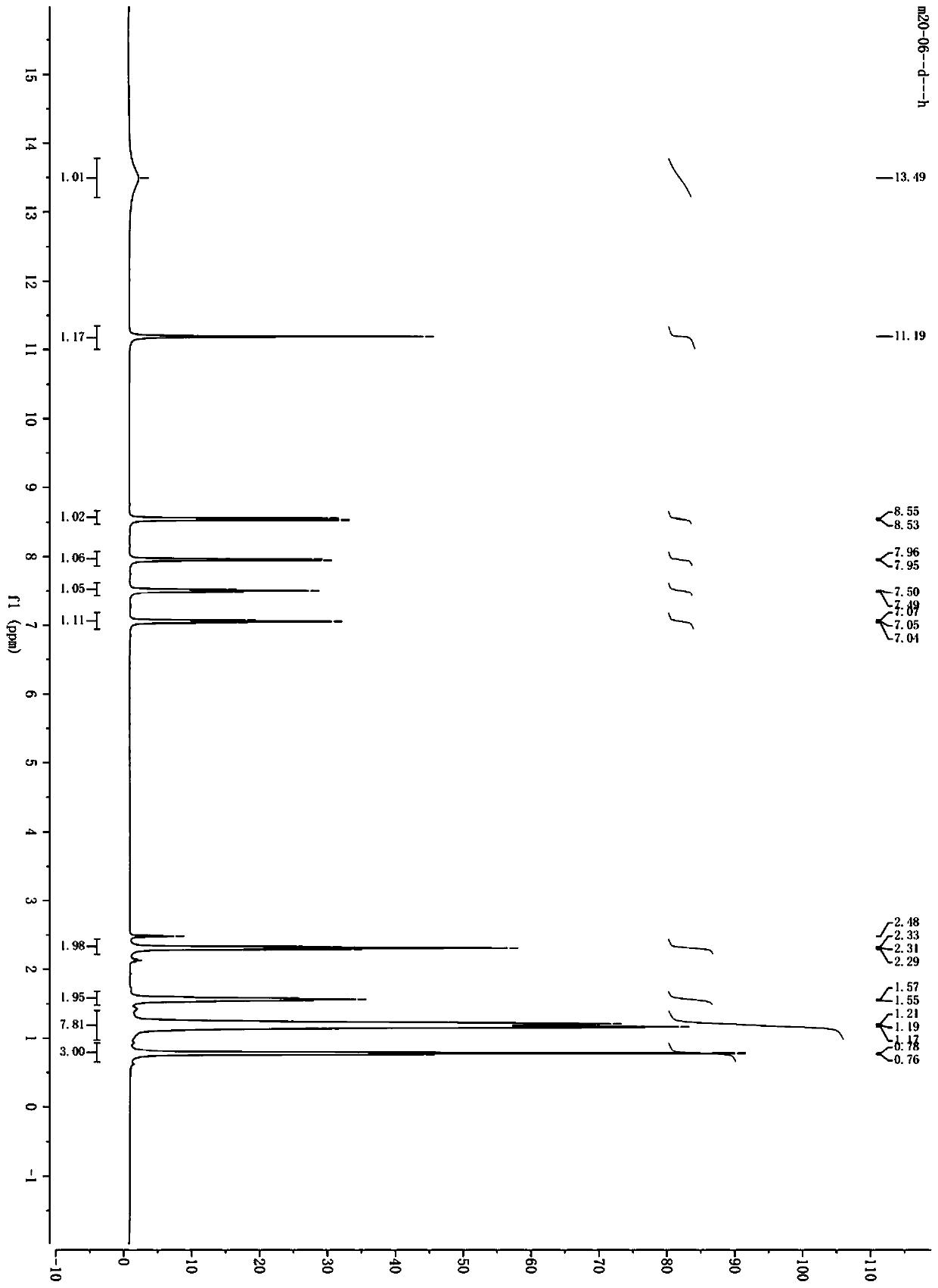

[0039] Synthesis of methyl octanoyl anthranilate

[0040]

[0041] 102g of methyl anthranilate and 93g of triethylamine were dissolved in 500ml of dichloromethane, cooled to -10°C, 100g of octanoyl chloride was dissolved in 500ml of dichloromethane, and added dropwise to the aforementioned mixture. Below 0°C, after the dropwise addition, the temperature was raised to room temperature, and the reaction was continued for 1 h. 500 ml of water was added to the reaction solution, and the layers were separated. The organic phase was washed twice with 500 ml of water, and the organic phase was concentrated to remove dichloromethane to obtain 138 g of a solid product. Yield 81%.

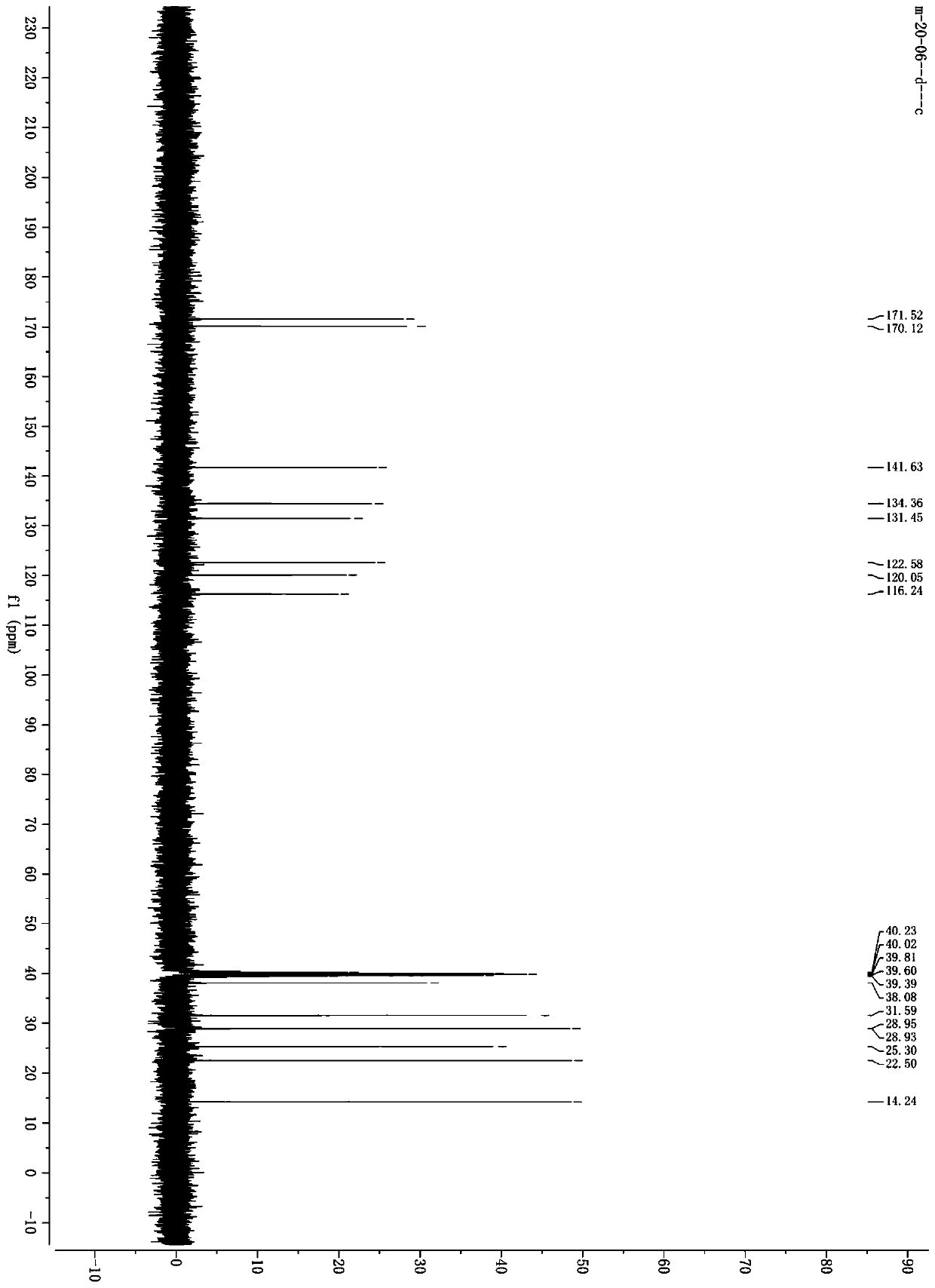

[0042] Synthesis of Octanoylanthranilic Acid

[0043]

[0044] Add 100g of methyl octanoyl anthranilate, add 200ml of ethanol, 300ml of water, 29g of sodium hydroxide, heat up to 50°C, stir until the solid is completely dissolved, continue to react at 50°C for 1 hour, the hydrolysis of the methyl este...

Embodiment 2

[0049] Synthesis of Methyl Lauroyl Anthranilate

[0050]

[0051]76g of methyl anthranilate and 69g of triethylamine were dissolved in 500ml of dichloromethane, cooled to -10°C, 100g of lauroyl chloride was dissolved in 500ml of dichloromethane, and added dropwise to the aforementioned mixture. The dropping process controlled the temperature at Below 0°C, after the dropwise addition, warm up to room temperature, continue the reaction for 1 h, add 500 ml of water to the reaction solution, separate layers, wash the organic phase with 500 ml of water twice, concentrate the organic phase to remove dichloromethane, and obtain 140 g of solid product, Yield 91.9%.

[0052] Synthesis of Lauroyl Anthranilic Acid

[0053]

[0054] Add 100g of methyl lauroyl anthranilate, add 200ml of ethanol, 300ml of water, 24g of sodium hydroxide, heat up to 50°C, stir until the solid is completely dissolved, continue to react at 50°C for 1 hour, the hydrolysis of the methyl ester is complete, ...

Embodiment 3

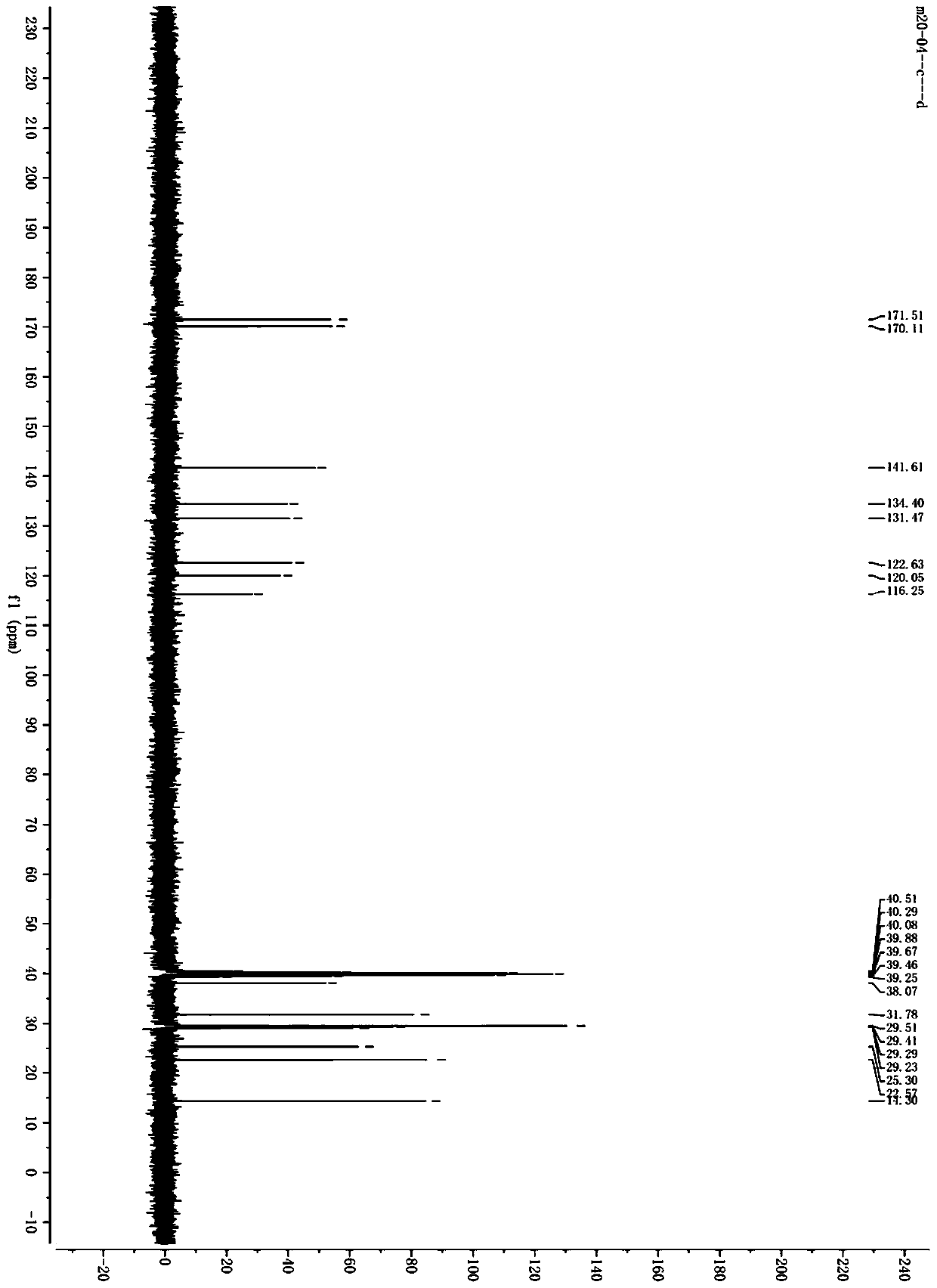

[0056] Synthesis of Methyl Palmitoyl Anthranilate

[0057]

[0058] Dissolve 60.4g of methyl anthranilate and 55g of triethylamine in 500ml of dichloromethane, cool down to -10°C, dissolve 100g of palmitoyl chloride in 500ml of dichloromethane, add dropwise to the aforementioned mixture, and control the temperature during the dropping process Below 0°C, after the dropwise addition, warm up to room temperature, continue the reaction for 1 h, add 500 ml of water to the reaction liquid, separate layers, wash the organic phase twice with 500 ml of water, concentrate the organic phase to remove dichloromethane, and obtain 107 g of solid product , yield 75.5%.

[0059] Synthesis of Palmitoylanthranilic Acid

[0060]

[0061] Add 100g of methyl lauroyl anthranilate, add 200ml of ethanol, 300ml of water, and 20.5g of sodium hydroxide, heat up to 50°C, stir until the solid is completely dissolved, continue to react at 50°C for 1 hour, the hydrolysis of the methyl ester is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com