Temperature difference oxygen production cup and application thereof

A water cup and temperature difference technology, applied in drinking vessels, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as ineffective effect, difficult storage, heat loss, etc., to improve breathing quality, low cost, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

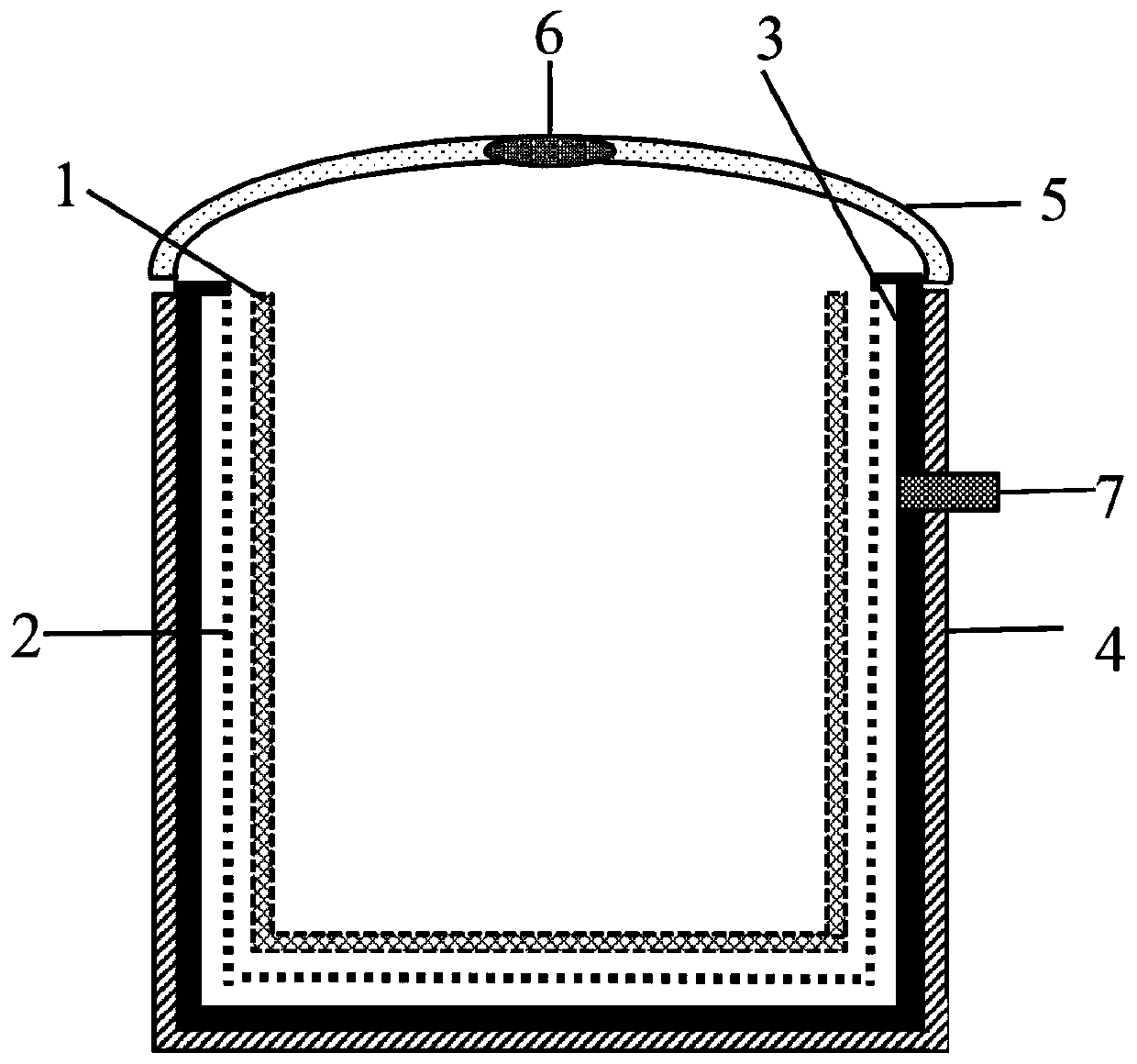

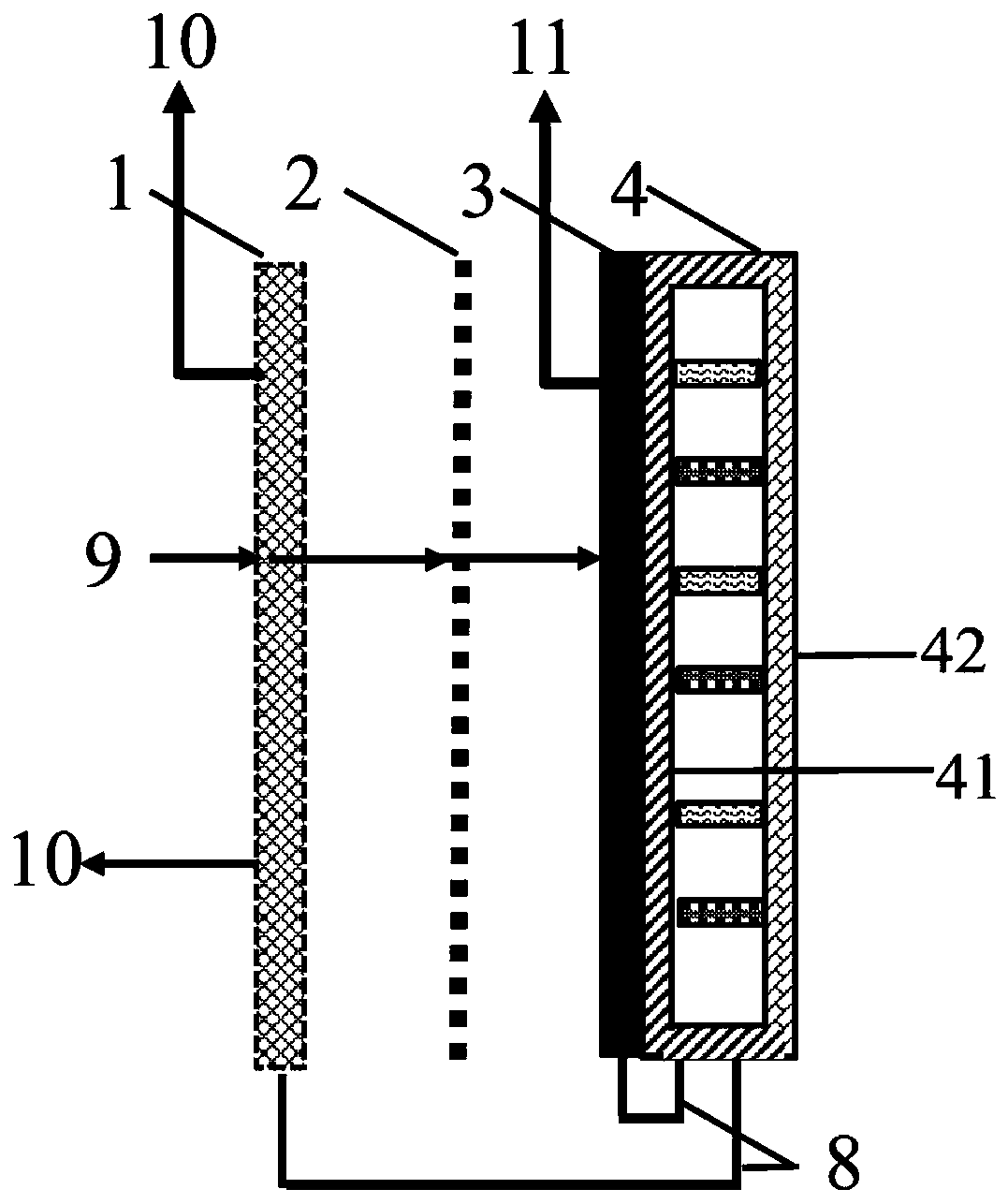

[0033] like figure 1 A thermoelectric oxygen-generating water cup is shown, including a cup cover 5, a thermally conductive cup body, a thermoelectric power generation sheet 4 fixedly arranged on the cup body, and an anode oxygen evolution electrode 1 and a cathode hydrogen evolution electrode 3 in contact with the water in the cup body The cup lid 5 is provided with an oxygen gas outlet 6, and the anode oxygen evolution electrode and the cathode hydrogen evolution electrode are relatively fixedly arranged. The negative electrode of sheet 4 is electrically connected by wire 8, the hot end 41 of the thermoelectric sheet is in thermal contact with the cup, and the cold end 42 of the thermoelectric sheet is located outside the cup and exposed to the environment.

[0034] In order to simplify the structure, the cathode hydrogen evolution electrode of this embodiment is used as a cup body. The cathode hydrogen evolution electrode includes a cup bottom and a cup wall made of hydroge...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the porous diaphragm between the two electrodes is a glass porous film, and a commercial iron-nickel alloy is used as the anode oxygen evolution electrode, and nickel metal is the cathode hydrogen production electrode as the driving power supply. The thermoelectric sheet is patterned and pasted on the outer wall of the cup body. The total area of the thermoelectric sheet is 9 square centimeters.

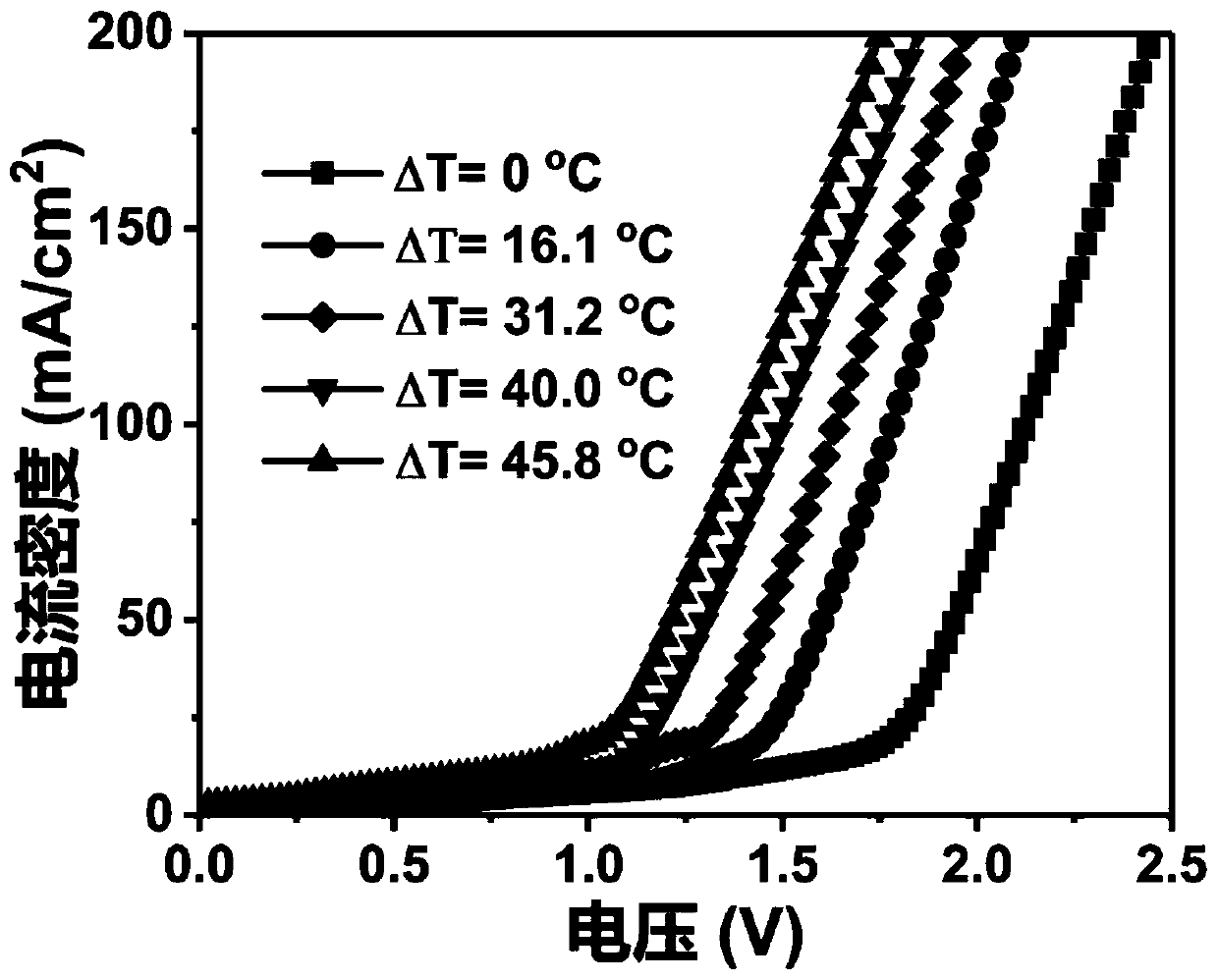

[0039] In order to confirm the effect of oxygen production, an experiment was carried out. During the experiment, the temperature difference between the inside and outside of the cup was controlled to be 1°C, 16.1°C, 31.2°C, 40.0°C and 45.8°C, and the different voltages generated were as follows: image 3 , when the temperature difference is 45.8°C, the corresponding hydrogen production and oxygen production are 0.482mmol / h and 0.248mmol / h respectively. Figure 4 As shown, the demand for oxygen production is ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com