Heat pipe auxiliary type heat dissipation system for cooling bearing on high-temperature molten salt pump

A technology of high-temperature molten salt and heat dissipation system, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of reducing thermal resistance, large space ratio, and low use cost, and achieves improved The effect of heat exchange efficiency, improved heat dissipation performance, and increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only suitable for explaining the present invention, but not limiting the present invention.

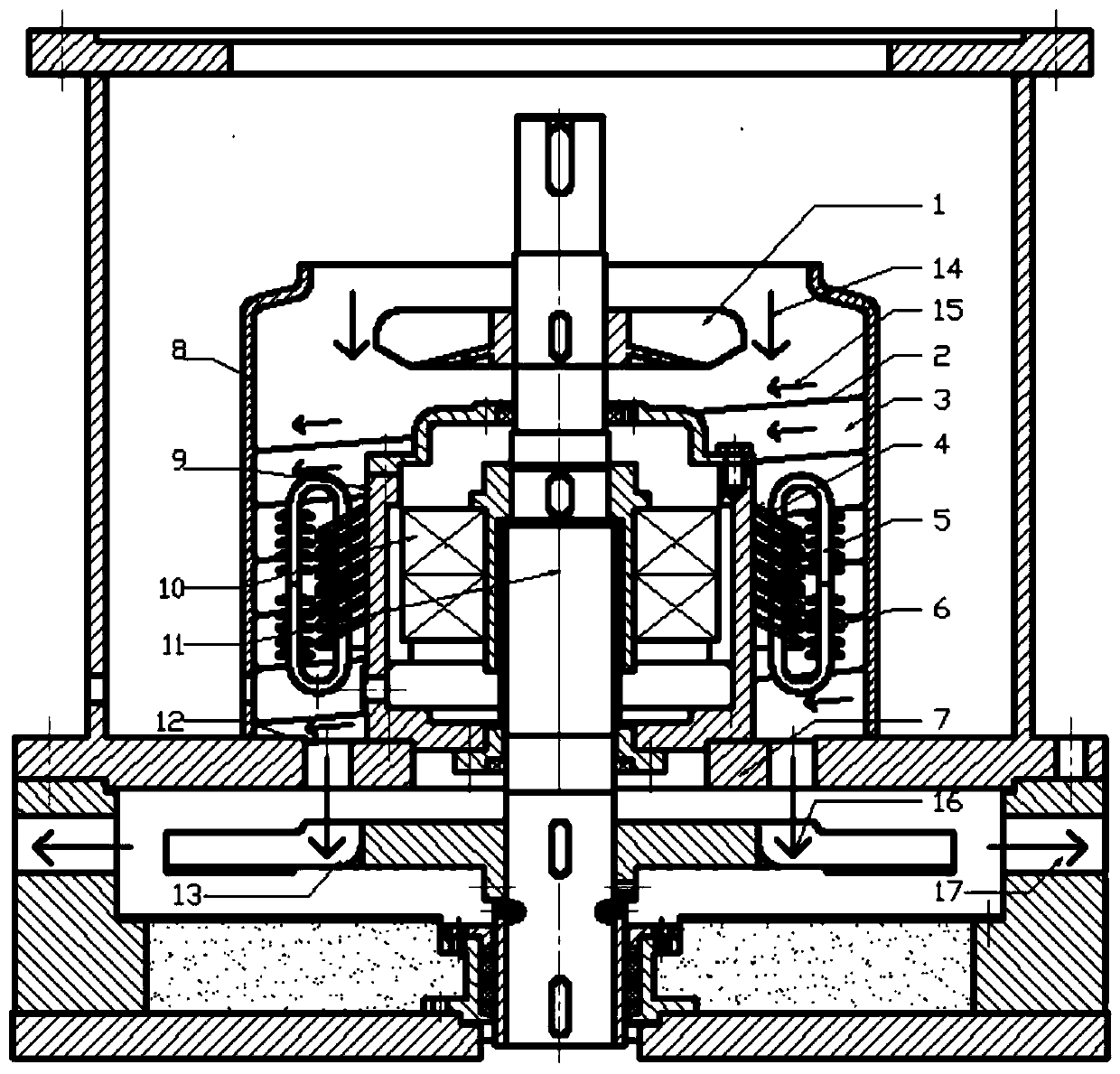

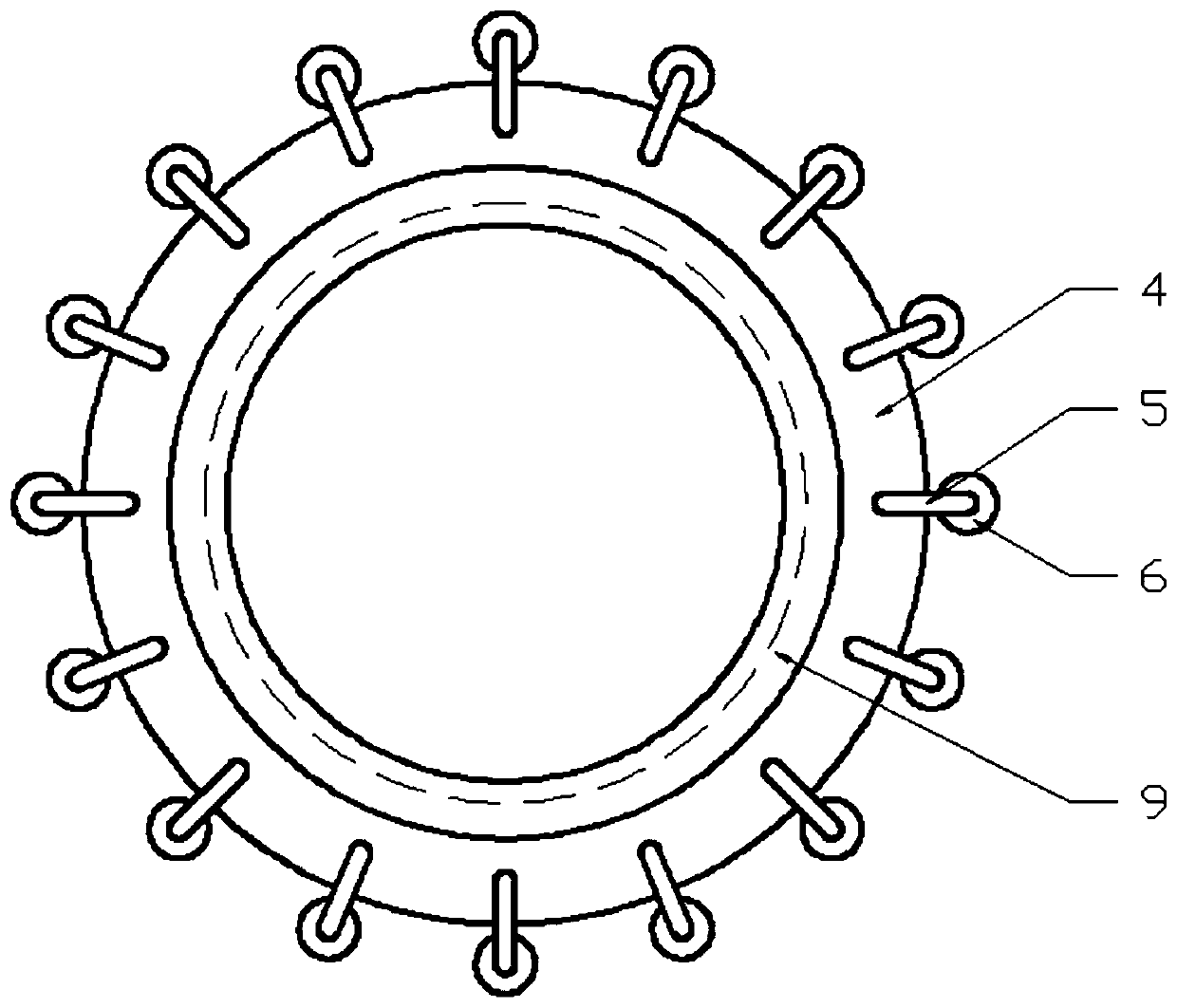

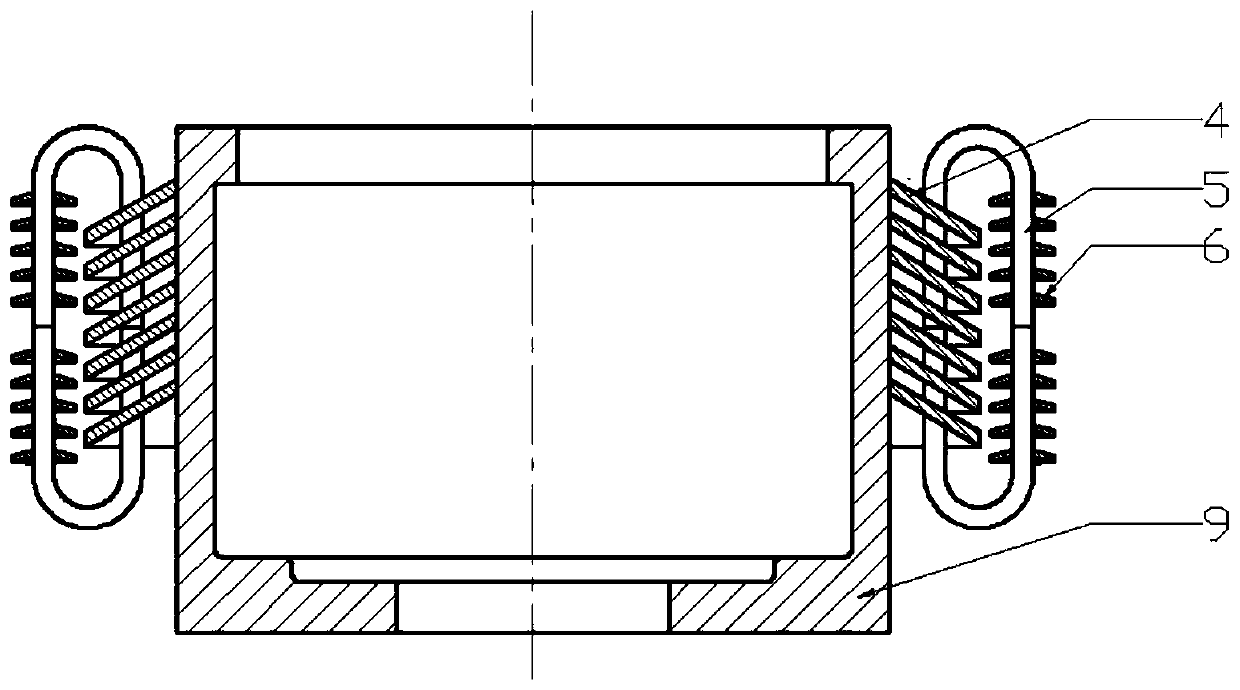

[0027] Such as figure 1 Shown: a heat pipe-assisted heat dissipation system for bearing cooling on high-temperature molten salt pumps, including a bearing housing 9, a heat exchange system, and an air cooling system. The heat exchange system consists of main heat dissipation fins 4 and U-shaped heat pipes 5 1. Umbrella-shaped cooling ribs 6 are connected by welding; The pump shaft 11 is housed inside the bearing housing 9, the bearing 10 is installed on the pump shaft 11, the outer wall of the bearing housing 9 is welded with the main cooling fins 4, and the vertical openings of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com