CFRP(BFRP) longitudinal bar-GFRP composite stirrup square pipe pile and design method

A-GFRP, design method technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as pipe pile loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

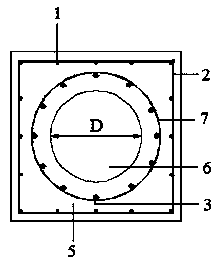

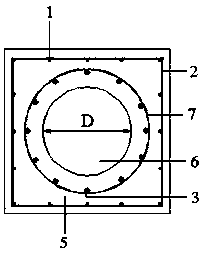

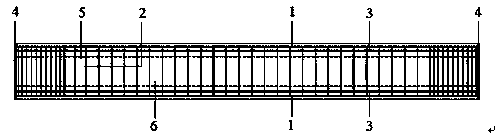

[0067] Aiming at the problems existing in the prior art, the present invention provides a pretensioned CFRP (BFRP) longitudinal bar-GFRP composite stirrup square pipe pile and its design method. figure 1 to attach image 3 The present invention is described in detail.

[0068] Such as Figure 1-Figure 3 As shown, the CFRP (BFRP) longitudinal reinforcement-GFRP composite stirrup square pipe pile provided by the embodiment of the present invention comprises: CFRP (BFRP) longitudinal reinforcement 1, GFRP stirrup 2, CFRP (BFRP) prestressed reinforcement 3, pile body end Plate 4, pile body concrete 5, pile body cavity 6, GFRP spiral reinforcement 7.

[0069] The CFRP (BFRP) longitudinal reinforcement-GFRP composite stirrup square pipe pile provided by the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com