Ultrafine tungsten carbide hard alloy with high-entropy alloy as binding phase and preparation method thereof

A technology of high-entropy alloys and hard alloys, applied in the field of composite materials, can solve problems such as limited effects and achieve excellent friction and wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing an ultrafine tungsten carbide cemented carbide with a high-entropy alloy as a binder phase, comprising the following steps:

[0027] S1. Preparation of nano five-component high-entropy alloy powder: in a glove box filled with argon, the molar ratios of Co, Cr, Ni, Cu, and Fe components range from 1 to 1.5 and mix them into a WC cemented carbide ball mill tank Among them, the mass ratio of ball and material is 10:1~20:1, the speed is 300~600r / min, the ball milling time is 30~60h, every turn 10h, stop for 30min to dissipate heat, stop every 10h to remove the sticky balls and the inner wall of the tank Scrape off the raw materials and mix them evenly, then add 0.2ml / 10g of anhydrous ethanol dispersant to the mixed powder and continue ball milling to obtain a nanometer CoCrNiCuFe powder with a fineness of 150nm or less;

[0028] S2. Preparation of nano-WC powder: The WC powder is ball-milled, the mass ratio of the b...

Embodiment 1

[0042] A method for preparing ultrafine tungsten carbide cemented carbide with high-entropy alloy as binder phase, its raw materials and proportioning ratio are shown in the following table,

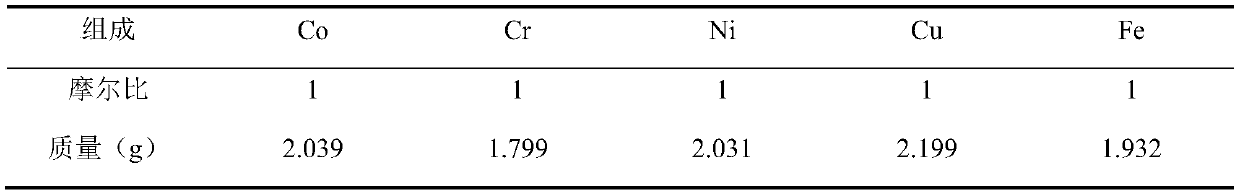

[0043] Table 1 Raw materials and mass ratios for preparing CoCrNiCuFe

[0044]

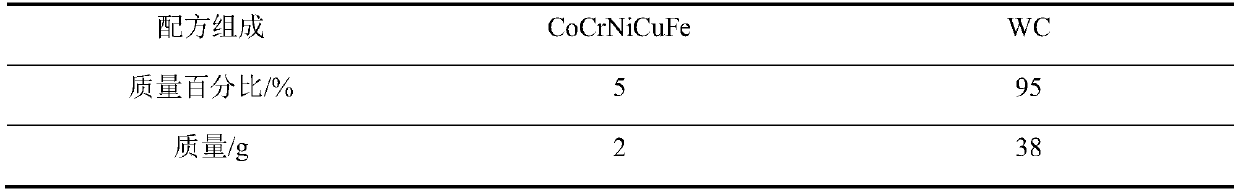

[0045] Table 2 prepares the raw material and its proportioning of 40g tungsten carbide cemented carbide

[0046]

[0047] The preparation method is as follows:

[0048] S1. In a glove box filled with argon, weigh 2.039g Co, 1.799g Cr, 2.031g Ni, 2.199g Cu and 1.932g Fe according to Table 1 and mix them into a WC cemented carbide ball mill jar. The ratio is 10:1, the rotating speed is 300r / min, the ball milling time is 60h, stop for 30min every 10h to dissipate heat, stop every 10h to scrape off the raw materials sticking to the grinding ball and the inner wall of the tank, and then add 0.2ml / 10g mixed powder The anhydrous ethanol dispersant of the raw material is continuously ball-milled to obtain a ...

Embodiment 2

[0056] A method for preparing ultrafine tungsten carbide cemented carbide with high-entropy alloy as binder phase, its raw materials and proportioning ratio are shown in the following table,

[0057] Table 4 prepares raw materials and mass ratios of CoCrNiCuFe

[0058]

[0059] Table 5 prepares the raw material and its proportioning of 40g tungsten carbide cemented carbide

[0060]

[0061] The preparation method is as follows:

[0062] S1. In a glove box filled with argon, weigh 2.039g Co, 1.799g Cr, 2.031g Ni, 2.199g Cu and 1.932g Fe according to Table 4 and mix them into a WC cemented carbide ball mill jar. The ratio is 10:1, the rotating speed is 400r / min, the ball milling time is 55h, every turn 10h, stop for 30min to dissipate heat, stop every 10h to scrape off the raw materials sticking to the grinding ball and the inner wall of the tank, and then add 0.2ml / 10g mixed powder The anhydrous ethanol dispersant of the raw material is continuously ball-milled to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com