PP plastic shell adhesive for storage battery and preparation method thereof

A kind of plastic case glue and storage battery technology, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems that cannot meet the sealing effect of PP plastic case batteries, PP plastic case is difficult to achieve heat sealing, etc., and achieve excellent Processability and mechanical properties, satisfying the sealing effect, and the effect of good instantaneous high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

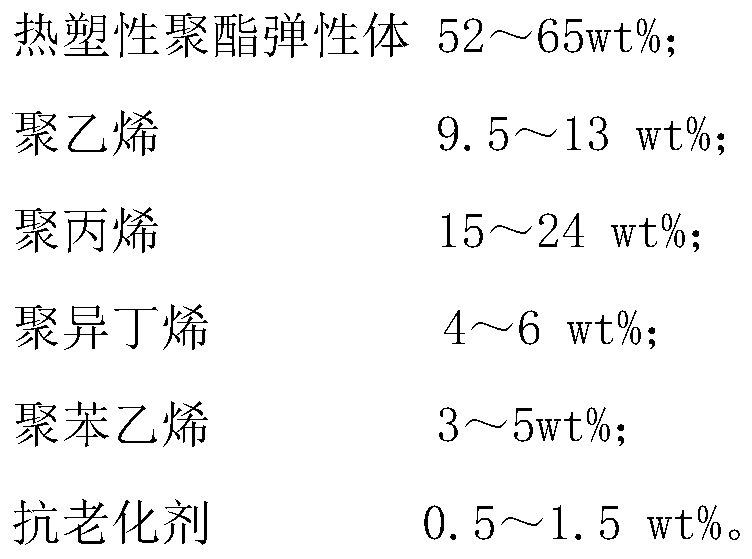

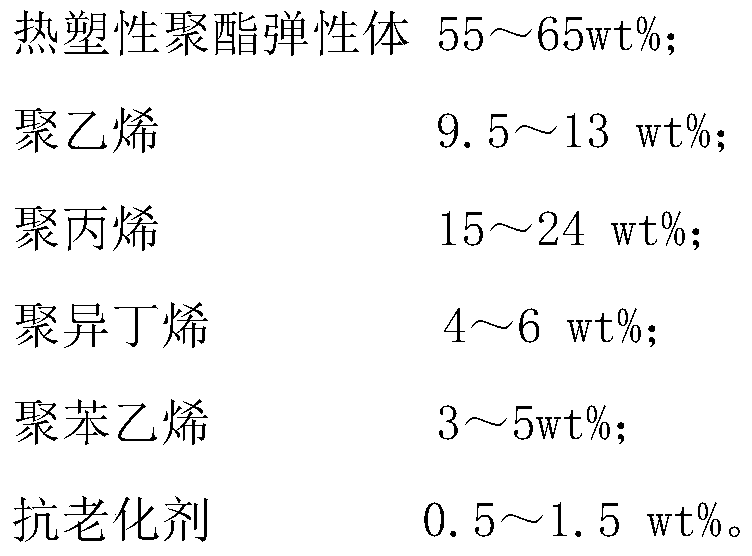

[0039] Example 1: Preparation of battery PP plastic case adhesive

[0040] Raw materials: see Table 1.

[0041] Preparation:

[0042] (1) Dehumidification and drying of raw materials Before production, first use microwave heating to dehumidify, the temperature is 80-90 ° C, and the time is 2-3 hours;

[0043] (2) mixing thermoplastic polyester elastomer, polyethylene, polypropylene, polyisobutylene, polystyrene, and antiaging agent raw materials with a mixer for use;

[0044] (3) Add the uniformly stirred mixture into a twin-screw extruder, and granulate by blending and extruding at a temperature of 170-200°C to prepare the required hot-melt adhesive particles, which is the battery PP Plastic case adhesive.

[0045] The consumption (wt %) table of each embodiment of table 1 and comparative example

[0046]

[0047]

Embodiment 2

[0048] Example 2: Preparation of battery PP plastic case adhesive

[0049] Raw materials: see Table 1.

[0050] Preparation:

[0051] (1) Dehumidification and drying of raw materials Before production, first use steam or other heating and dehumidification methods, the temperature is 80-90 ° C, and the time is 2-3 hours;

[0052] (2) mixing thermoplastic polyester elastomer, polyethylene, polypropylene, polyisobutylene, polystyrene, and antiaging agent raw materials with a mixer for use;

[0053] (3) Keep the uniformly stirred mixed material in the reactor at a temperature of 170-200°C and stir at high speed for 10-30 minutes;

[0054] (4) Casting the prepared PP hot-melt adhesive into the molding cavity for cooling and molding, thereby preparing the desired shape of the hot-melt adhesive. That is, the battery PP plastic case adhesive is obtained.

Embodiment 3

[0055] Example 3: Preparation of battery PP plastic case adhesive

[0056] Raw materials: see Table 1.

[0057] Preparation method: with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com