Polylactic acid/nano hydroxyapatite composite material and its preparation method and application

A nano-hydroxyapatite and composite material technology, applied in the field of biomedicine, can solve the problems of product mechanical properties decline, polylactic acid is easy to thermally degrade, and low impact strength, so as to improve mechanical properties and avoid low impact strength, Minimizes the effect of thermal degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

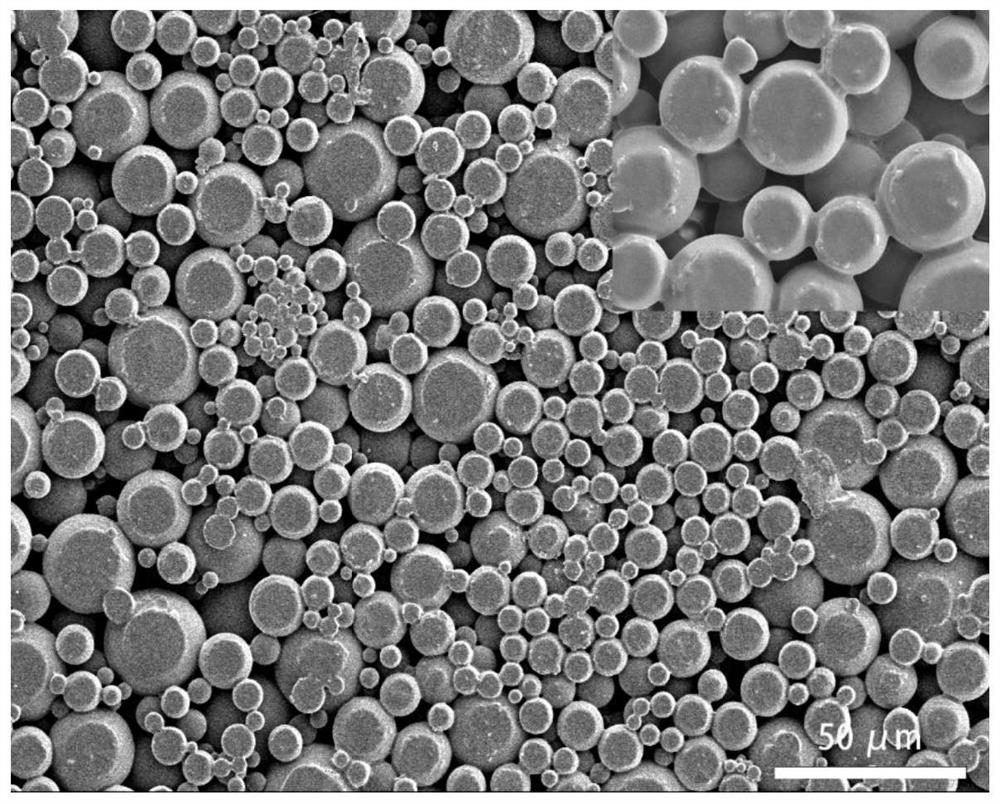

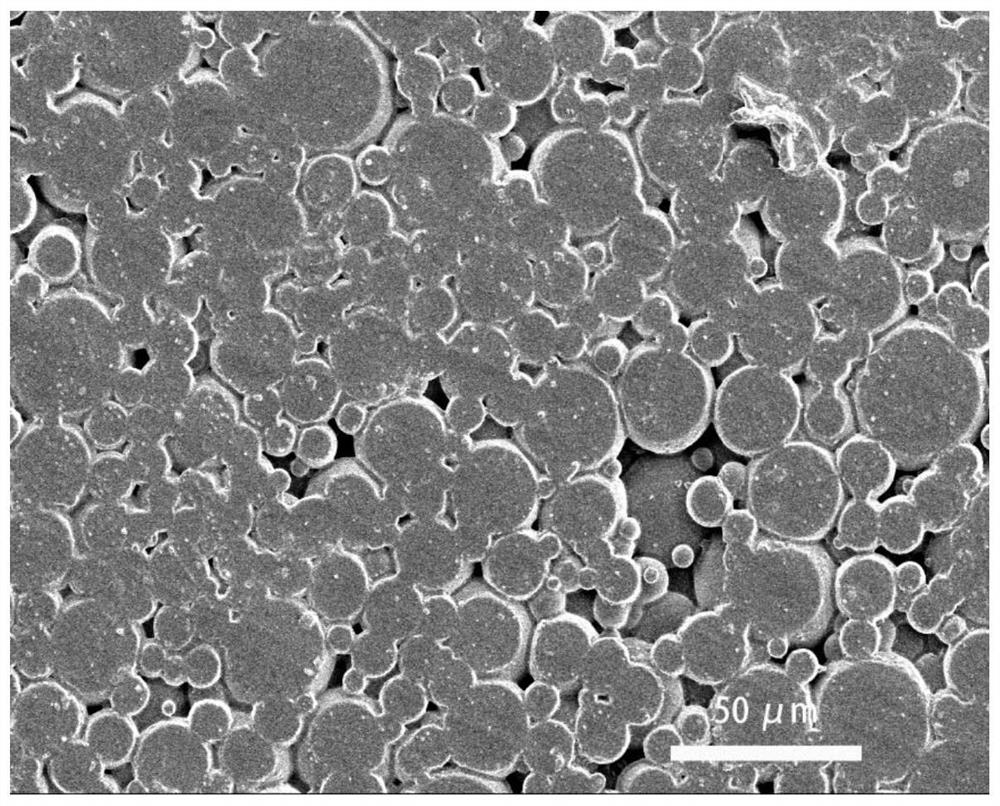

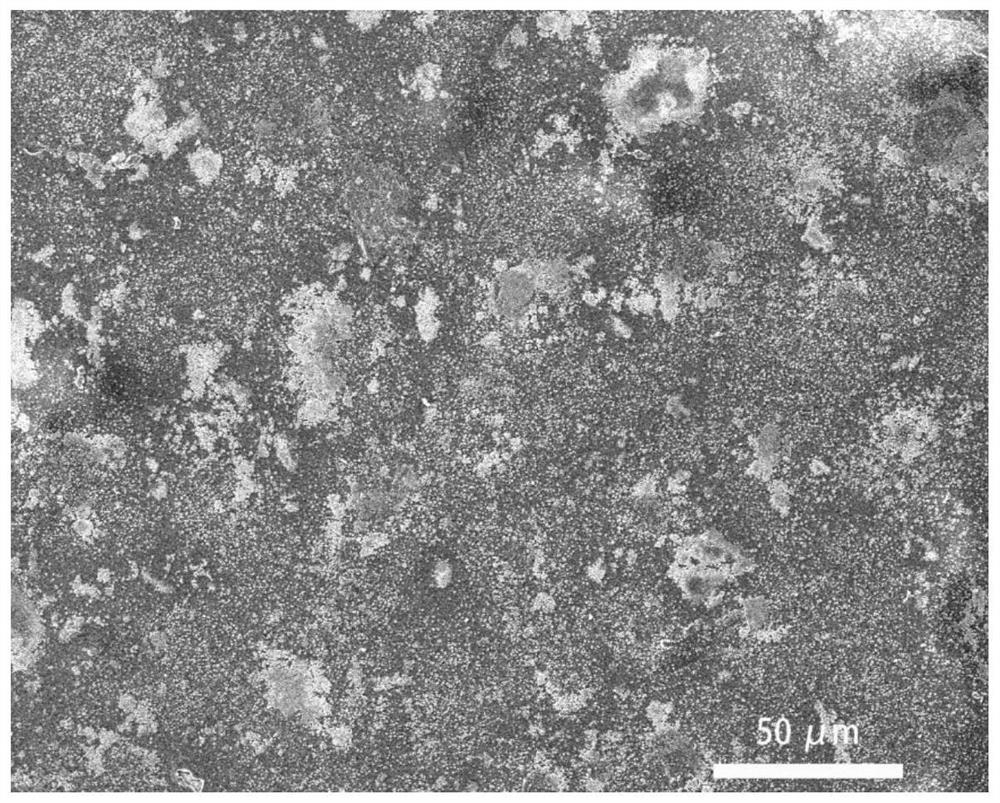

Image

Examples

Embodiment 1

[0032] A preparation method of polylactic acid / nano hydroxyapatite composite material, specifically comprising the following steps:

[0033] 1) Precipitation method is used to prepare nano-hydroxyapatite at 37°C: prepare an aqueous solution of calcium chloride with a concentration of 0.0668mol / L and an aqueous solution of diammonium hydrogen phosphate with a concentration of 0.04mol / L, and follow the Ca / P molar ratio of 1.67 After mixing the calcium chloride aqueous solution and the diammonium hydrogen phosphate aqueous solution, the pH value of the mixed solution is controlled at 9-10 with a sodium hydroxide aqueous solution with a concentration of 1mol / L, and then heated in a constant temperature water bath at 37°C Stir for 3 hours, then stand still for 24 hours, filter with suction, wash with deionized water, and freeze-dry to obtain white powdery nano-hydroxyapatite with a particle size of 50nm-80nm for subsequent use;

[0034] 2) Polylactic acid / nano-hydroxyapatite compos...

Embodiment 2

[0041] A preparation method of polylactic acid / nano hydroxyapatite composite material, specifically comprising the following steps:

[0042] 1) Precipitation method is used to prepare nano-hydroxyapatite at 37°C: prepare an aqueous solution of calcium chloride with a concentration of 0.0668mol / L and an aqueous solution of diammonium hydrogen phosphate with a concentration of 0.04mol / L, and follow the Ca / P molar ratio of 1.67 After mixing the calcium chloride aqueous solution and the diammonium hydrogen phosphate aqueous solution, the pH value of the mixed solution is controlled at 9-10 with a sodium hydroxide aqueous solution with a concentration of 1mol / L, and then heated in a constant temperature water bath at 37°C Stir for 3 hours, then stand still for 24 hours, filter with suction, wash with deionized water, and freeze-dry to obtain white powdery nano-hydroxyapatite with a particle size of 50nm-80nm for subsequent use;

[0043] 2) Polylactic acid / nano-hydroxyapatite compos...

Embodiment 3

[0050] A preparation method of polylactic acid / nano hydroxyapatite composite material, specifically comprising the following steps:

[0051] 1) Precipitation method is used to prepare nano-hydroxyapatite at 37°C: prepare an aqueous solution of calcium chloride with a concentration of 0.0668mol / L and an aqueous solution of diammonium hydrogen phosphate with a concentration of 0.04mol / L, and follow the Ca / P molar ratio of 1.67 After mixing the calcium chloride aqueous solution and the diammonium hydrogen phosphate aqueous solution, the pH value of the mixed solution is controlled at 9-10 with a sodium hydroxide aqueous solution with a concentration of 1mol / L, and then heated in a constant temperature water bath at 37°C Stir for 3 hours, then stand still for 24 hours, filter with suction, wash with deionized water, and freeze-dry to obtain white powdery nano-hydroxyapatite with a particle size of 50nm-80nm for subsequent use;

[0052] 2) Polylactic acid / nano-hydroxyapatite compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com