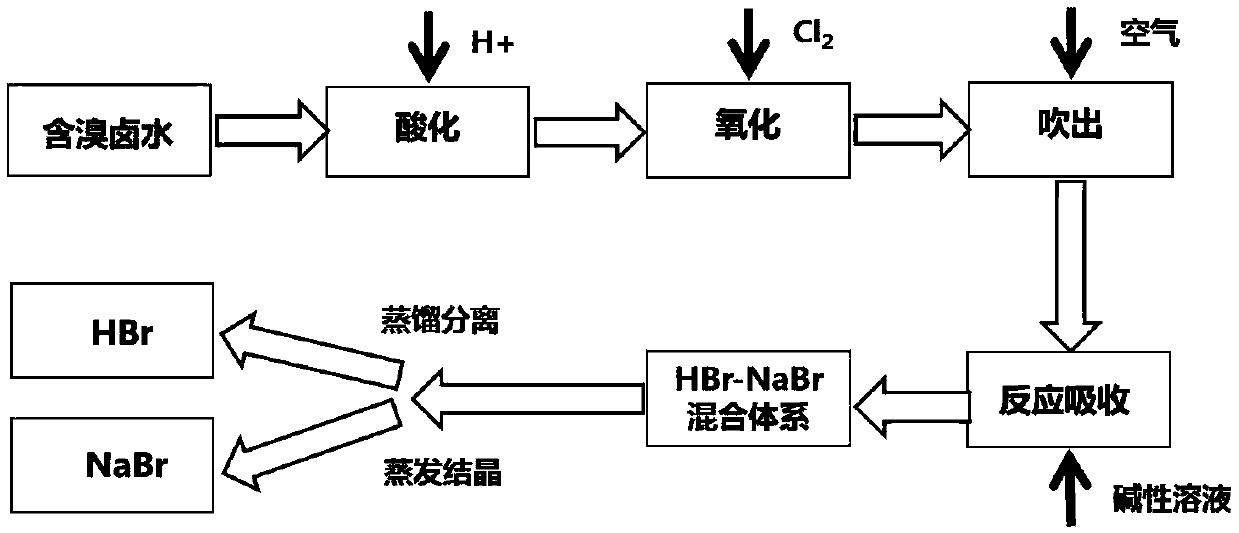

Method for preparing hydrobromic acid and sodium bromide from bromine-containing brine in short process

A hydrobromic acid and short-process technology, applied in the direction of bromine/hydrogen bromide, hydrogen bromide, alkali metal bromide, etc., can solve the problems of low utilization rate of raw materials, reduce energy consumption, simplify preparation steps, and reduce pollution The effect of sexual exhaust gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of method for preparing hydrobromic acid and sodium bromide by bromine-containing brine short process

[0025] Take 100L raw material brine containing bromine 950mg / L, put it in a 150L oxidation reactor, add sulfuric acid, hydrochloric acid or nitric acid under normal temperature conditions, adjust the pH value between 0-6.5, blow in chlorine gas under acidic conditions, The chlorine gas flow rate is 5L / min, bromide ions are oxidized into bromine simple substance.

[0026] The oxidized bromine-containing raw material liquid enters the blowing tower from the top of the blowing tower (diameter 60mm, height 1500mm) through the spraying device. The liquid ratio is 100, and the countercurrent contact with the bromine-containing raw material liquid is carried out to desorb the free bromine in the gaseous state. The air carrying gaseous free bromine enters the absorption tower (diameter 60mm, height 1500mm), contacts with the absorption lye in countercurr...

Embodiment 2

[0029] Embodiment 2: a kind of method that bromine-containing brine short process prepares hydrobromic acid and sodium bromide

[0030] Get 100L of raw material brine containing bromine 950mg / L, place it in a 150L oxidation reactor, under normal temperature conditions, add sulfuric acid, adjust the pH value to be controlled between 0-6.5, blow in chlorine gas under acidic conditions, and the gas flow rate of blowing in chlorine gas is 10L / min, bromide ions are oxidized into bromine simple substance.

[0031] The oxidized bromine-containing raw material liquid enters the blow-out tower from the top of the blowing tower (diameter 60 mm, height 1500 mm) through a spray device, and at the same time, air enters the blowing tower from the bottom of the tower through a blower, and carries out countercurrent contact with the bromine-containing raw material liquid. The gaseous free bromine is decomposed. The air carrying gaseous free bromine enters the absorption tower (diameter 60mm,...

Embodiment 3

[0034] Embodiment 3: A kind of method for preparing hydrobromic acid and sodium bromide in short process of bromine-containing brine

[0035] Take 100L raw material brine containing bromine 950mg / L, place it in a 150L oxidation reactor, add hydrochloric acid at 30°C, adjust the pH value to 3, and bubble chlorine gas under acidic conditions at a flow rate of 10L / min, bromide ions are oxidized to simple bromide.

[0036] The oxidized bromine-containing raw material liquid enters the blow-out tower from the top of the blowing tower (diameter 60 mm, height 1500 mm) through a spray device, and at the same time, air enters the blowing tower from the bottom of the tower through a blower, and carries out countercurrent contact with the bromine-containing raw material liquid. The gaseous free bromine is decomposed. The air carrying gaseous free bromine enters the absorption tower (diameter 60mm, height 1500mm), contacts with the absorption lye in countercurrent or cocurrent contact a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com