Band-pass filter based on fan-shaped microstrip resonant cavity

A band-pass filter and microstrip resonance technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problem of large filter insertion loss, achieve good stop-band characteristics, good out-of-band suppression characteristics, and parameter adjustment. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

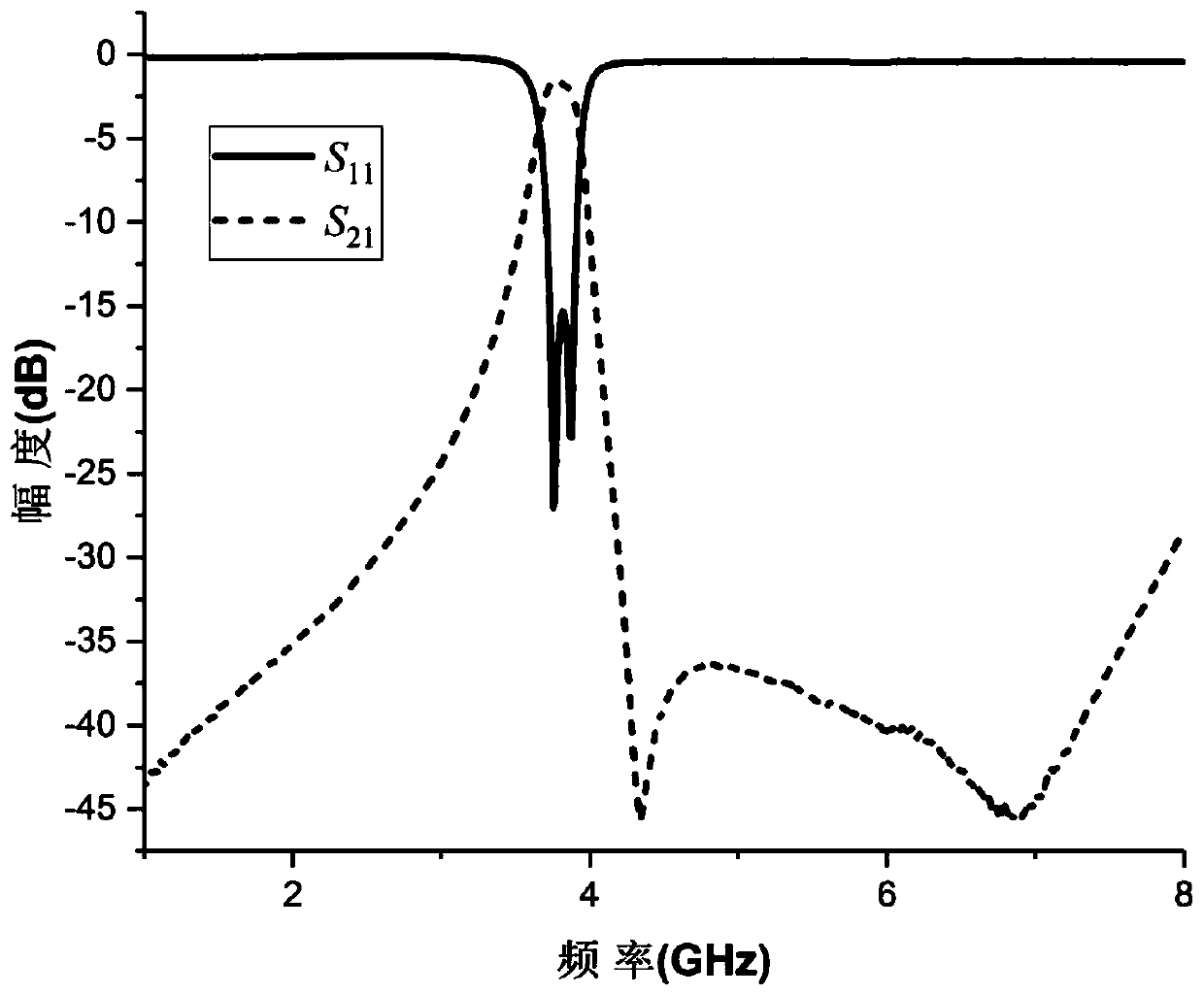

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

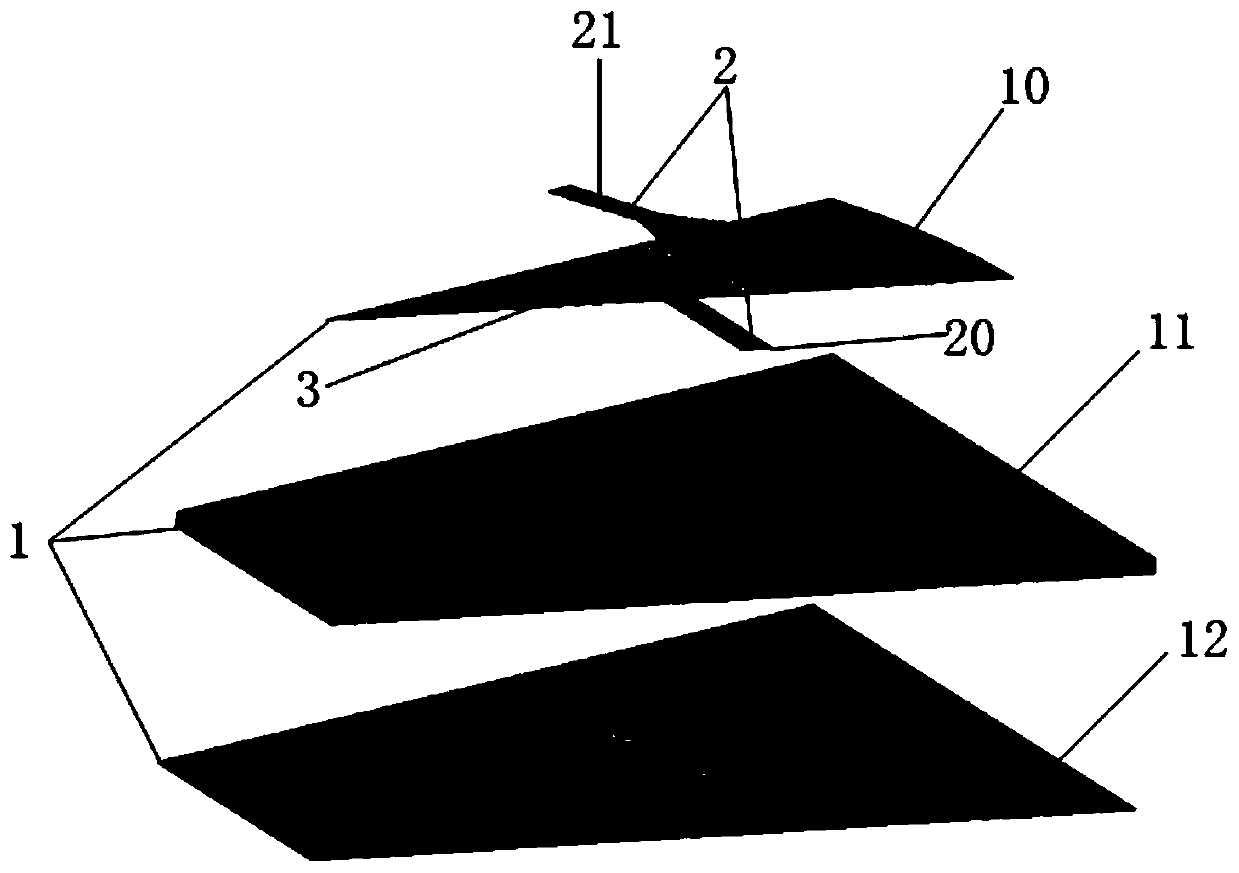

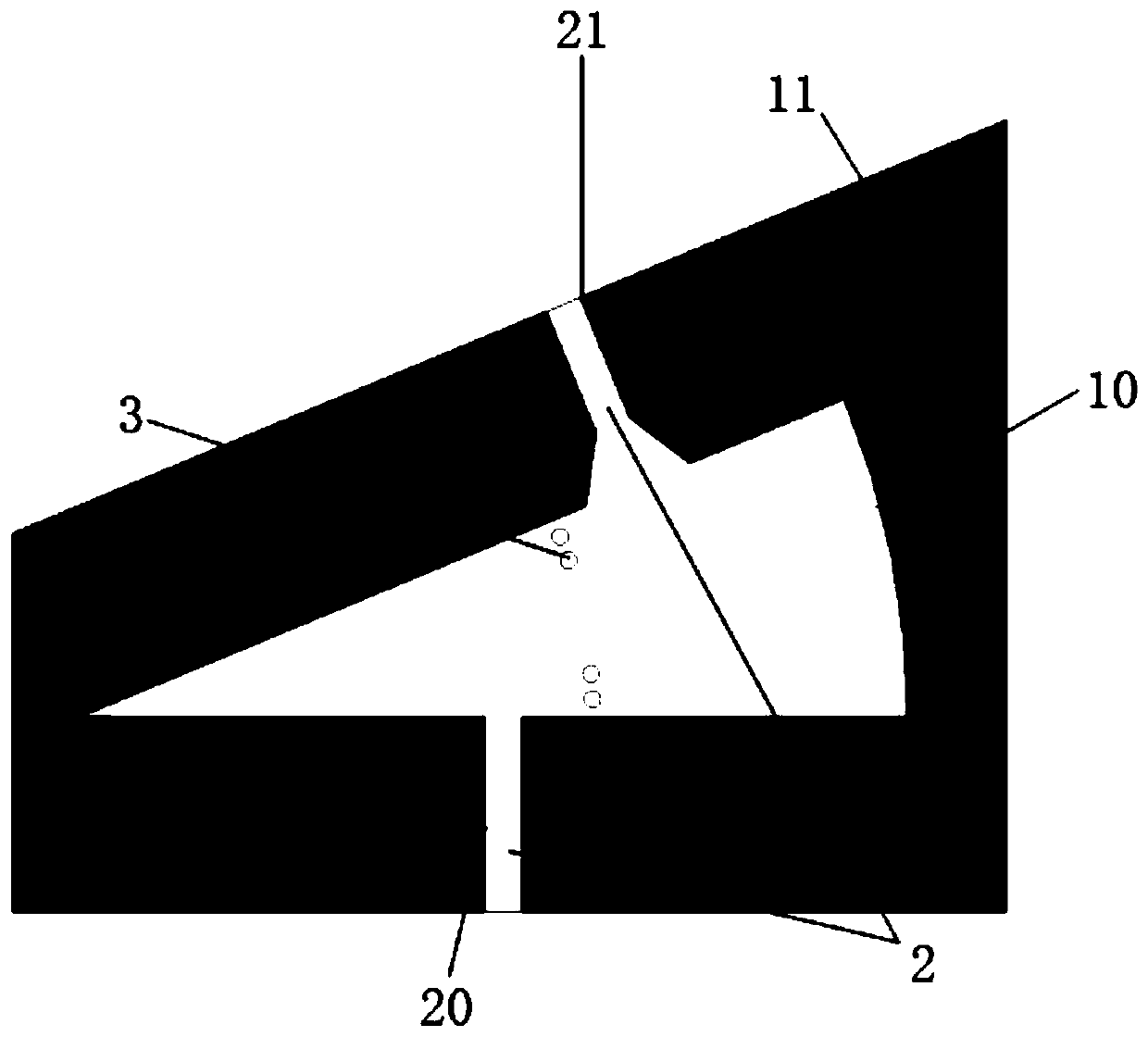

[0020] figure 1 It is a schematic diagram of the overall structure of a specific embodiment of the present invention, including a fan-shaped microstrip resonator 1 , input and output feeders 2 and metallized through holes 3 . The fan-shaped microstrip resonator 1 is sequentially formed by stacking the top fan-shaped metal patch 10, the single-layer dielectric substrate 11 of the middle layer and the bottom metal patch 12 from top to bottom. The radius of the top fan-shaped metal patch 10 It is 27mm, the radian is 22.5°, the thickness is 0.017mm, and the size is equivalent to one sixteenth of the circular metal patch with the same radius. The single-layer dielectric substrate 11 of the middle layer is a low-loss TaconicRF-35 with a thickness of 0.508 mm. It is in the shape of a right-angled trapezoid, with an upper base length of 11.46 mm, a lower base length of 23.92 mm, and a height of 30.1 mm. The size of the bottom metal patch 12 is the same as that of the single-layer die...

Embodiment 2

[0024]In this embodiment, the shapes of the single-layer dielectric substrate 11 and the bottom metal patch 12 of the middle layer are changed from a right-angled trapezoid to any other shape at the same time, while ensuring the shape of the single-layer dielectric substrate 11 of the middle layer and the bottom metal patch 12 The same size and its outer frame size needs to exceed the outer frame size of the fan-shaped metal patch 10 on the top layer plus the input and output feeder 2, and the input and output feeder ports need to be in the outer outline of the single-layer dielectric substrate 11 and the bottom metal patch 12 in the middle layer Online, other parts are completely the same as those in Embodiment 1, and the functions of the present invention can still be realized.

Embodiment 3

[0026] In this embodiment, the transmission line structure of the input and output feeder 2 is changed from a gradual transmission line to a step impedance transmission line structure, and other parts are completely the same as in the first embodiment, and the functions of the present invention can still be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com