High-anti-recovery silver alloy for jewelry and preparation method of high-anti-recovery silver alloy

A silver sulfide, high resistance technology, applied in the field of silver jewelry, can solve the problems of silver alloy discoloration, jewelry easy to bump and wear, film damage, etc., achieve high anti-sulfurization performance and improve the effect of anti-sulfurization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-resistance silver sulfide alloy for jewelry, comprising the following elements in percentage by weight: 1-8% copper, 0-6% zinc and 0.1-1.5% nickel, and the balance is silver; a part of nickel is combined with copper and / or zinc A metal compound is formed, and the metal compound wraps another part of nickel to form a quincunx-shaped product and then disperses in the matrix mainly composed of silver.

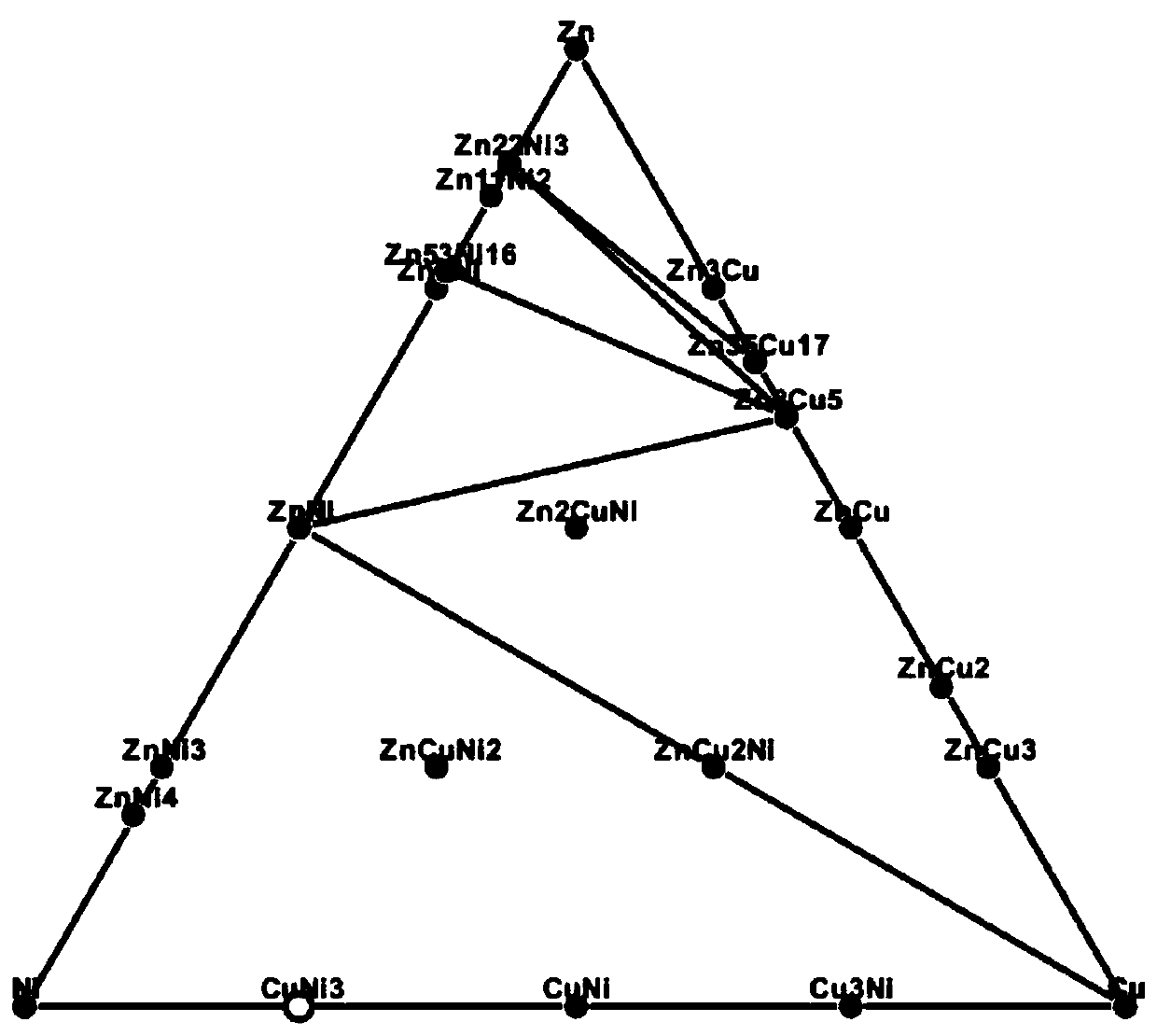

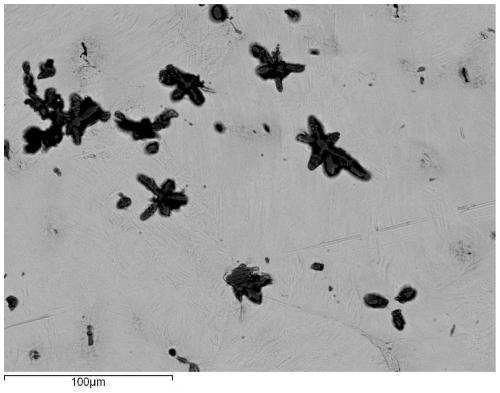

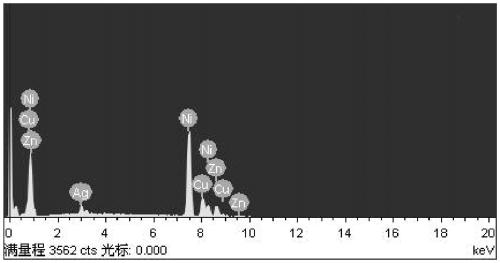

[0028] see figure 1 Part of the nickel forms copper-nickel, zinc-nickel, zinc-copper, copper-zinc-nickel and other metal compounds with copper and / or zinc, and then wraps another part of nickel to form a quincunx-shaped product. After being dispersed in the silver matrix system, it appears as follows figure 2 The structure shown, in this structure, the metal compound improves the anti-sulfidation ability of the silver alloy by changing the electrochemical properties of the silver alloy. The jewelry made of the silver alloy of the invention has high vulcanization re...

Embodiment 2

[0037] A high-resistance silver sulfide alloy for jewelry, comprising the following elements by weight percentage: 1-8% copper, 0.1-6% zinc and 0.1-1.5% nickel, the balance being silver; a part of nickel is combined with copper and / or zinc A metal compound is formed, and the metal compound wraps another part of nickel to form a quincunx-shaped product and then disperses in a matrix mainly composed of silver; the content ratio between the copper and the zinc is 1.4-1.8. The samples with copper-zinc content ratio in the range of 1.4-1.8 have better anti-sulfurization ability than the samples outside this range.

Embodiment 3

[0039] A high-resistance silver sulfide alloy for jewelry, comprising the following elements by weight percentage: 1-8% copper, 0.1-6% zinc, 0.1-1.5% nickel and 0.2-2% titanium, the balance being silver; a part of nickel Combined with copper and / or zinc to form a metal compound, the metal compound wraps another part of nickel to form a quincunx-shaped product and then disperses in a silver-based matrix. By adding a trace amount of titanium element, the fluidity of the silver alloy can be improved and casting defects can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com