Thermal insulation suit fabric and preparation process thereof

A technology for fabrics and suits, applied in the field of fabric preparation, can solve problems such as poor compatibility and reduced thermal performance, and achieve uniform thermal resistance and improve thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

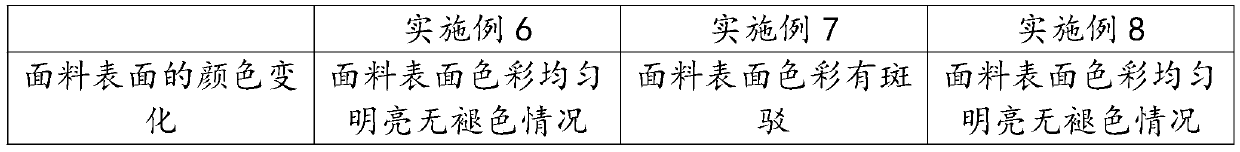

Examples

Embodiment 1

[0024] The concrete preparation process of phase change microcapsule emulsion is as follows:

[0025] Step 1: Weigh 3.1g of sodium dodecylbenzenesulfonate, 10g of tetradecyl alcohol and 12g of water into a reaction vessel and raise the temperature to 65-70°C and stir and mix for 10-15min to obtain an aqueous phase;

[0026] Step 2: Weigh 10g of polyethylene glycol 400 and add it to water and stir to dissolve, then add 3.6g of isophorone diisocyanate to it, mix well, add 2.4g of the water phase prepared in step 1 to it, and then heat up to 50- Stir and react at 55° C. for 10-12 hours to obtain a phase-change microcapsule emulsion.

Embodiment 2

[0028] The concrete preparation process of phase change microcapsule emulsion is as follows:

[0029] Step 1: Weigh 3.1g of sodium dodecylbenzenesulfonate, 10g of tetradecyl alcohol and 12g of water into a reaction vessel and raise the temperature to 65-70°C and stir and mix for 10-15min to obtain an aqueous phase;

[0030]Step 2: Weigh 10g of methyl acrylate and add it into ethanol and stir to dissolve, then add 4.3g of benzoyl peroxide and 11.3g of isobutyl acrylate to it, mix well and add 2.4g of the water phase prepared in step 1 to it, Then the temperature was raised to 80-85° C. and stirred for 10-12 hours to obtain a phase-change microcapsule emulsion.

Embodiment 3

[0032] The concrete preparation process of antioxidant is as follows:

[0033] (1) Weigh 10 g of acrylic acid and add it to 30 g of thionyl chloride solution, heat up to 60-70° C. for reflux reaction for 4-5 hours, and then carry out vacuum distillation to obtain acryloyl chloride;

[0034] (2) Add 10g of 2,4-dihydroxybenzophenone and 90mL of acetone into the reaction kettle at the same time, and add phosphoric acid solution to it to adjust the pH of the solution to 1, then raise the temperature to 60-65°C and pour it into the reaction vessel drop by drop Add 12.3g of the acryloyl chloride prepared in step (1), raise the temperature to 90-95°C and stir for 8-9h after the addition is complete, then add 2.3g of anhydrous aluminum chloride to the reaction kettle in portions, and raise the temperature to 160-165°C heat preservation reaction for 3-4h, then lower the temperature to 50-60°C, and add 1mol / L hydrochloric acid solution to it, stir and react for 1-1.5h, then stand for st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com