Cotton fabric with antiviral function and preparation method thereof

A cotton fabric, anti-virus technology, applied in the field of textile fabric processing, can solve the problems of easy aggregation of germs and viruses, increase user infection, reduce utility and other problems, and achieve the effects of low cost, reduced side reactions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

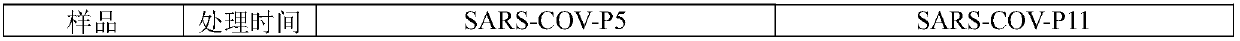

Examples

Embodiment 1

[0025] A kind of preparation method with antiviral function cotton fabric, comprises the steps:

[0026] 1. Put 1kg of cotton fabric into 9L of 40g / L cellulase solution with a specific activity of 100U / g, treat it at 55°C for 24 minutes, and then treat it with plasma. The conditions are: the gas is nitrogen, the processing power is 200W, and the pressure is 52Pa, the processing time is 28min;

[0027] 2. Grind 1kg gallnut bark with liquid nitrogen, add 7.2L PBS buffer solution to extract at 4°C for 24 hours, filter the extract with an ultrafiltration membrane with a molecular weight cut-off of 42kDa, and spray dry the ultrafiltration permeate to obtain gallnut tree bark extract;

[0028] 3. Soak 0.5g of the cotton fabric treated in step 1 in 50mL of 1-ethyl-3-methylimidazolium tetrafluoroboron containing 65g / L pyromellitic dianhydride and 120g / L gallnut bark extract at 32°C salt for 20 hours, dry-cleaned and dried with tetrachlorethylene;

[0029] 4. Soak 0.5g of the cotton...

Embodiment 2

[0031] A kind of preparation method with antiviral function cotton fabric, comprises the steps:

[0032] 1. Put 1kg of cotton fabric into 8L of 20g / L cellulase solution with a specific activity of 50U / g, treat it at 30°C for 20 minutes, and then treat it with plasma. The conditions are: the gas uses nitrogen, the processing power is 100W, and the pressure is 50Pa, the processing time is 20min;

[0033] 2. Grind 1kg gallnut bark with liquid nitrogen, add 4L PBS buffer solution to extract at 2°C for 24 hours, filter the extract with an ultrafiltration membrane with a molecular weight cut-off of 50kDa, and spray dry the ultrafiltration permeate to obtain Gallnut bark Extract;

[0034] 3. Soak 0.5g of the cotton fabric treated in step 1 in 25mL of 1-butyl-3-methylimidazolium hexafluorophosphate containing 30g / L pyromellitic dianhydride and 60g / L gallnut bark extract at 25°C In salt for 12 hours, dry-clean and dry with tetrachlorethylene;

[0035] 4. Soak 0.5g of the cotton fabr...

Embodiment 3

[0037] A kind of preparation method with antiviral function cotton fabric, comprises the steps:

[0038] 1. Put 1kg of cotton fabric into 10L of 50g / L cellulase solution with a specific activity of 150U / g, treat it at 60°C for 30 minutes, and then treat it with plasma. The conditions are: the gas is nitrogen, the processing power is 300W, and the pressure is 60Pa, the processing time is 30min;

[0039] 2. Grind 1kg gallnut bark with liquid nitrogen, add 8L PBS buffer solution to extract at 8°C for 24 hours, filter the extract with an ultrafiltration membrane with a molecular weight cut-off of 40kDa, and spray dry the ultrafiltration permeate to obtain Gallnut bark Extract;

[0040] 3. Soak 0.5g of the cotton fabric treated in step 1 in 100mL 37°C 1-butyl-3-methylimidazolium hexafluorophosphate containing 70g / L pyromellitic dianhydride and 200g / L gallnut bark extract In salt for 24 hours, dry cleaning and drying with hydrocarbon cleaning agent;

[0041] 4. Soak 0.5 g of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com