A kind of CR-doped ZNS intermediate zone thin film and preparation method thereof

A technology for film preparation and intermediate zone, which is applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems such as the inability of light absorption intensity to meet the requirements and the uneven distribution of crystal particles in the Cr-ZnS film. Achieve the effect of improving light absorption intensity, enhancing photocurrent, and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

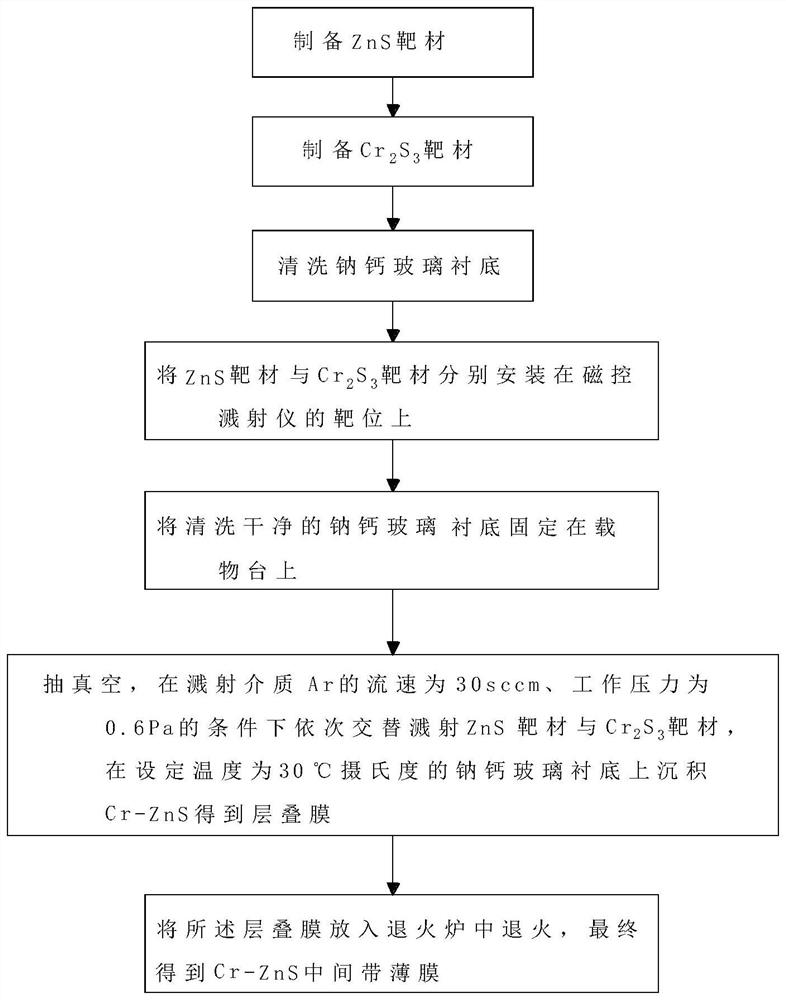

[0057] see figure 1 Preparation process, a method for preparing a Cr-doped ZnS intermediate zone film in this embodiment, the method steps are as follows:

[0058] Step 1: preparing a ZnS target; select a circular target with a diameter of 65mm, a purity of 99.99%, and a thickness of 5mm. Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0059] Step 2: Preparation of Cr 2 S 3 Target material; choose Cr with a thickness of 3mm and a purity of 99.99% 2 S 3 . Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0060] Step 3: Clean the soda-lime glass substrate, first cut the soda-lime glass substrate into 2cm×2cm, clean the surface dirt and debris with detergent, then ultrasonically use deionized water for 20min, and then soak in 10% dilute sulfuric acid After 20 minutes, take out the soda-lime glass substrate and clean it with deionized water; put the cleaned soda-lime glass substrate into carbon tetrachloride, acetone, and absolute ethanol in turn for...

Embodiment 2

[0068] For the preparation process, please refer to figure 1 , a method for preparing a Cr-doped ZnS intermediate zone thin film of the present embodiment, the method steps are as follows:

[0069] Step 1: preparing a ZnS target; select a circular target with a diameter of 65mm, a purity of 99.99%, and a thickness of 5mm. Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0070] Step 2: Preparation of Cr 2 S 3 Target material; choose Cr with a thickness of 3mm and a purity of 99.99% 2 S 3 . Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0071] Step 3: Clean the soda-lime glass substrate, first cut the soda-lime glass substrate into 2cm×2cm, clean the surface dirt and debris with detergent, then ultrasonically use deionized water for 20min, and then soak in 10% dilute sulfuric acid After 20 minutes, take out the soda-lime glass substrate and clean it with deionized water; put the cleaned soda-lime glass substrate into carbon tetrachloride, acetone...

Embodiment 3

[0079] For the preparation process, please refer to figure 1 , a method for preparing a Cr-doped ZnS intermediate zone thin film of the present embodiment, the method steps are as follows:

[0080] Step 1: preparing a ZnS target; select a circular target with a diameter of 65mm, a purity of 99.99%, and a thickness of 5mm. Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0081] Step 2: Preparation of Cr 2 S 3 Target material; choose Cr with a thickness of 3mm and a purity of 99.99% 2 S 3 . Manufacturer: Beijing Xingyou Economic and Trade Co., Ltd.

[0082] Step 3: Clean the soda-lime glass substrate, first cut the soda-lime glass substrate into 2cm×2cm, clean the surface dirt and debris with detergent, then ultrasonically use deionized water for 20min, and then soak in 10% dilute sulfuric acid After 20 minutes, take out the soda-lime glass substrate and clean it with deionized water; put the cleaned soda-lime glass substrate into carbon tetrachloride, acetone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com