one for co 2 Reduced photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as large impact on profit and income, damage to geological structures, secondary leakage, etc., to achieve improved photocatalytic activity , increase the lifespan, and improve the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

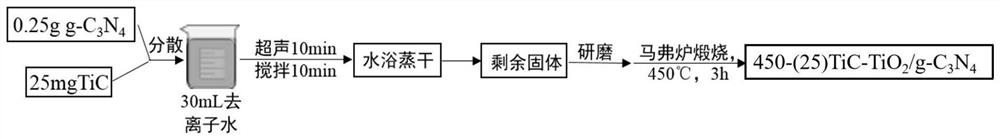

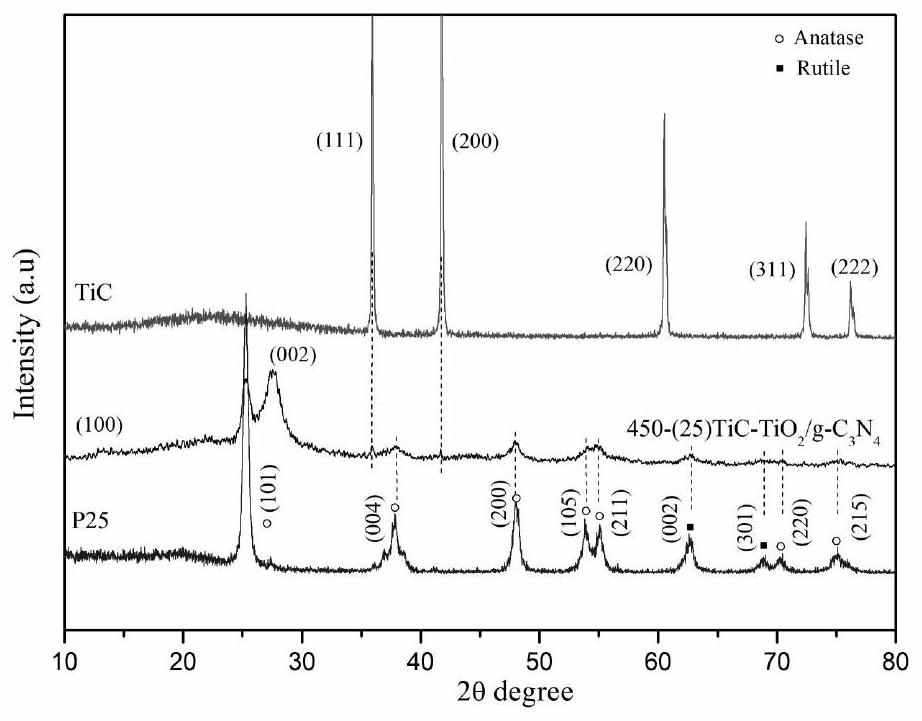

[0038]Embodiment 1: composite catalyst TiC-TiO 2 / g -C 3 N 4 method of preparation. 0.25g g-C 3 N 4 Disperse in a beaker filled with 30mL of deionized water, weigh 25mg of TiC and put it into the above mixture, and perform ultrasonic treatment for 10min and stirring for 10min, wherein the stirring speed is 1000 rad / min, and then transfer the mixture to a water bath , and evaporated to dryness in a water bath at 80° C. at a speed of 500 rad / min. After evaporating to dryness, the remaining solid was taken out and ground, and then placed in a muffle furnace for calcination. The calcination temperature was 450°C, the heating rate was 5°C / min, and the calcination time was 3h, so that TiC was partially oxidized to TiO 2 , the obtained sample is recorded as 450-(25)TiC-TiO 2 / g -C 3 N 4 . attached figure 1 Represents 450-(25)TiC-TiO 2 / g -C 3 N 4 A schematic diagram of the preparation process.

Embodiment 2

[0041] Embodiment 2: preparation method is the same as embodiment 1, and its difference is that in the preparation process of catalyst, directly to g-C 3 N 4 Add 10mg TiC and 15mg TiO to the mixture 2 Nanoparticles (5–7nm) in tube furnaceN 2 Calcined at 550°C for 3 hours in the atmosphere, the heating rate was 5°C / min, TiC was not oxidized, and the obtained sample was recorded as 450-TiC / TiO 2 / g -C 3 N 4 .

Embodiment 3

[0042] Example 3: The preparation method is the same as in Example 1, the difference is that during the preparation of the catalyst, the calcination temperature in the muffle furnace is 400 ° C, and the obtained sample is recorded as 400-(25)TiC-TiO 2 / g -C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com