Low-temperature cured outdoor super-weather-resistant and corrosion-resistant powder coating and preparation method thereof

A powder coating and ultra-weather-resistant technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as poor results, save curing energy consumption, ensure coating stability, and excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

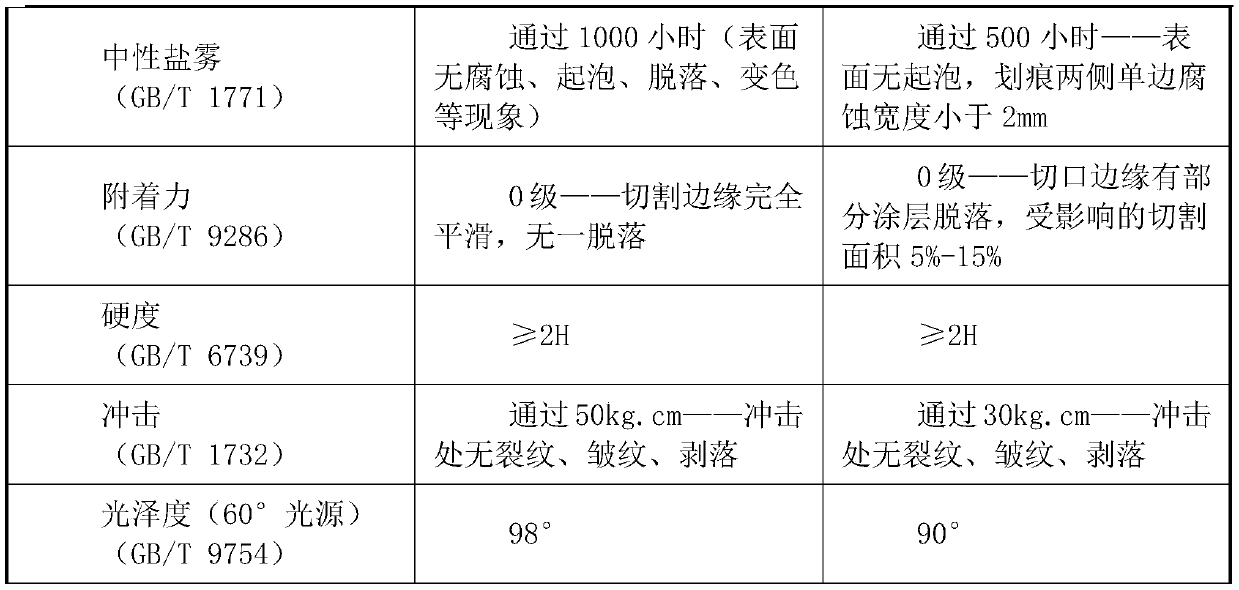

Image

Examples

Embodiment

[0035] Preparation of super weather-resistant polyester resin:

[0036] Put neopentyl glycol and terephthalic acid into the reaction device according to the reaction ratio, and at the same time use monobutyltin oxide accounting for 0.05% of the mass of the reactant as a catalyst and trimethylolpropane accounting for 2% of the mass of the reactant Chain agent, filled with nitrogen to protect, heat up to 160°C to start esterification reaction, and distill water, control the heating rate to 250°C to keep warm, react to 95% of the theoretical value, add phthalic acid blocking agent accounting for 10% of the mass of the reactant , Reaction at 240-250°C for 40-50 minutes, vacuum polycondensation for 40-60 minutes to obtain super weather-resistant polyester resin.

[0037] Preparation of low-temperature curing outdoor super weather-resistant and corrosion-resistant powder coatings

[0038] Prepare the following components in parts by mass: 100 parts of super weather-resistant polyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com