Mechanical movement conversion device

A technology of conversion device and mechanical movement, applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., can solve the problem that the function of the equipment cannot be fully exerted, and achieve simple structure, wide application and high conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

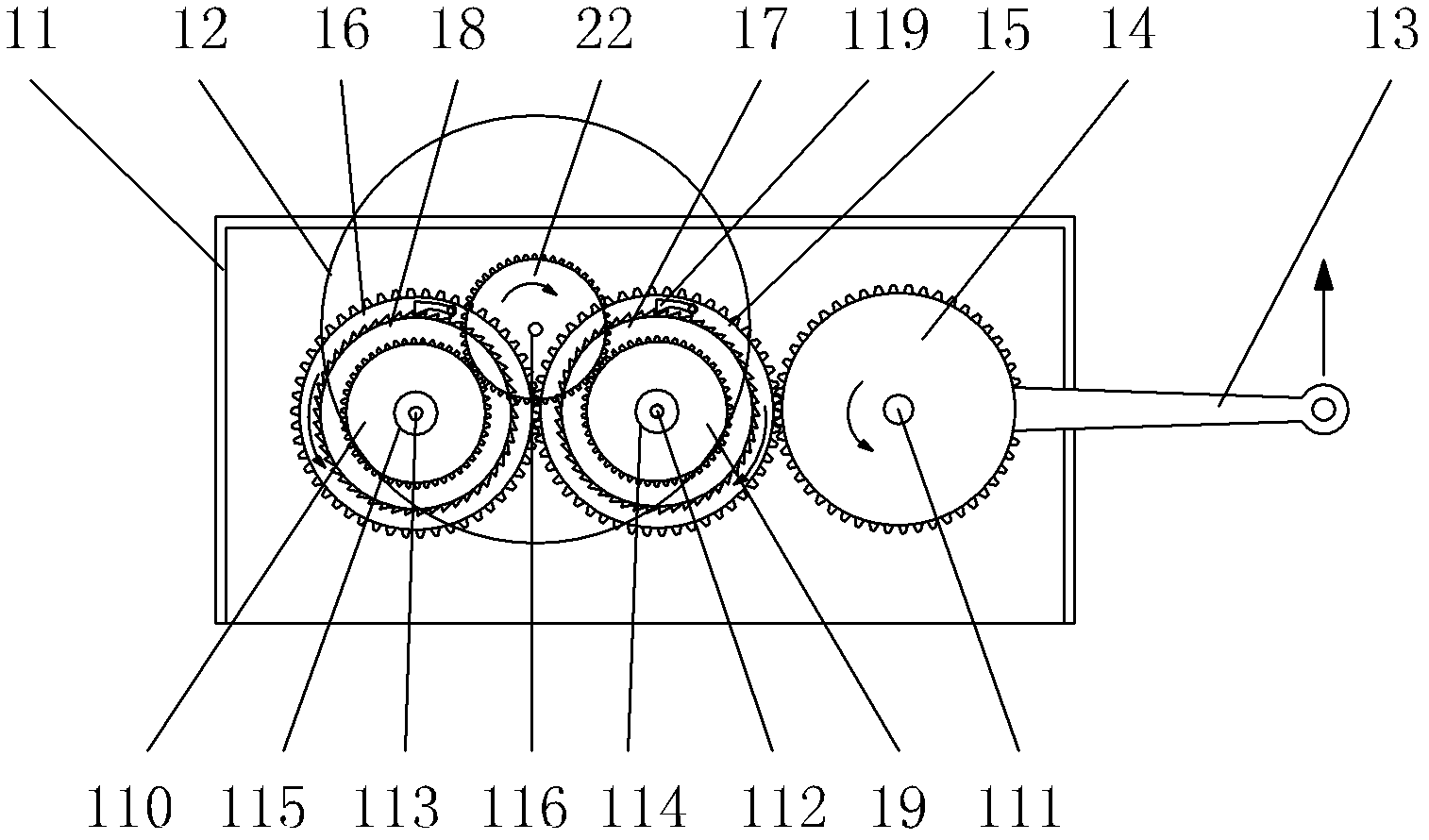

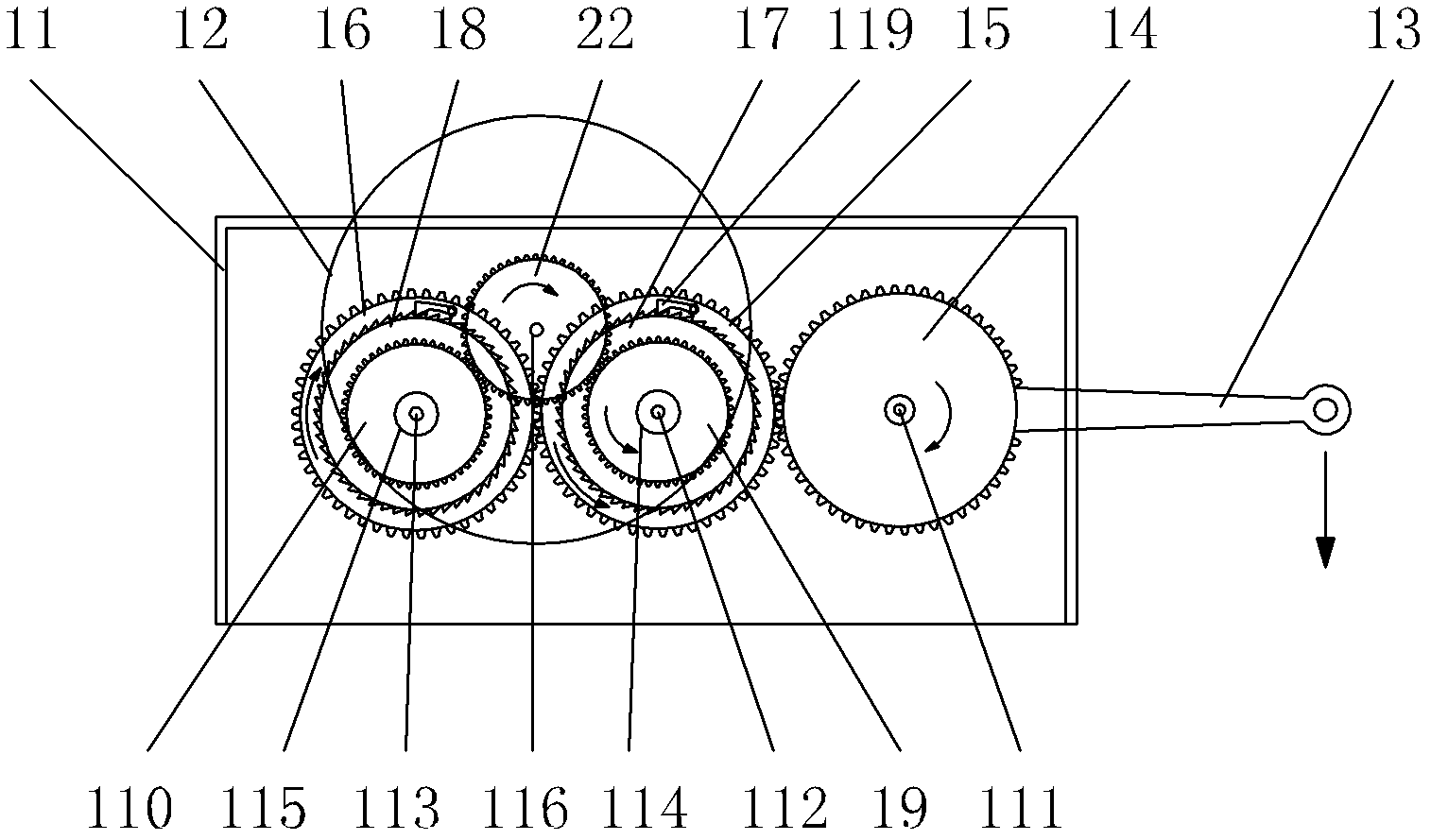

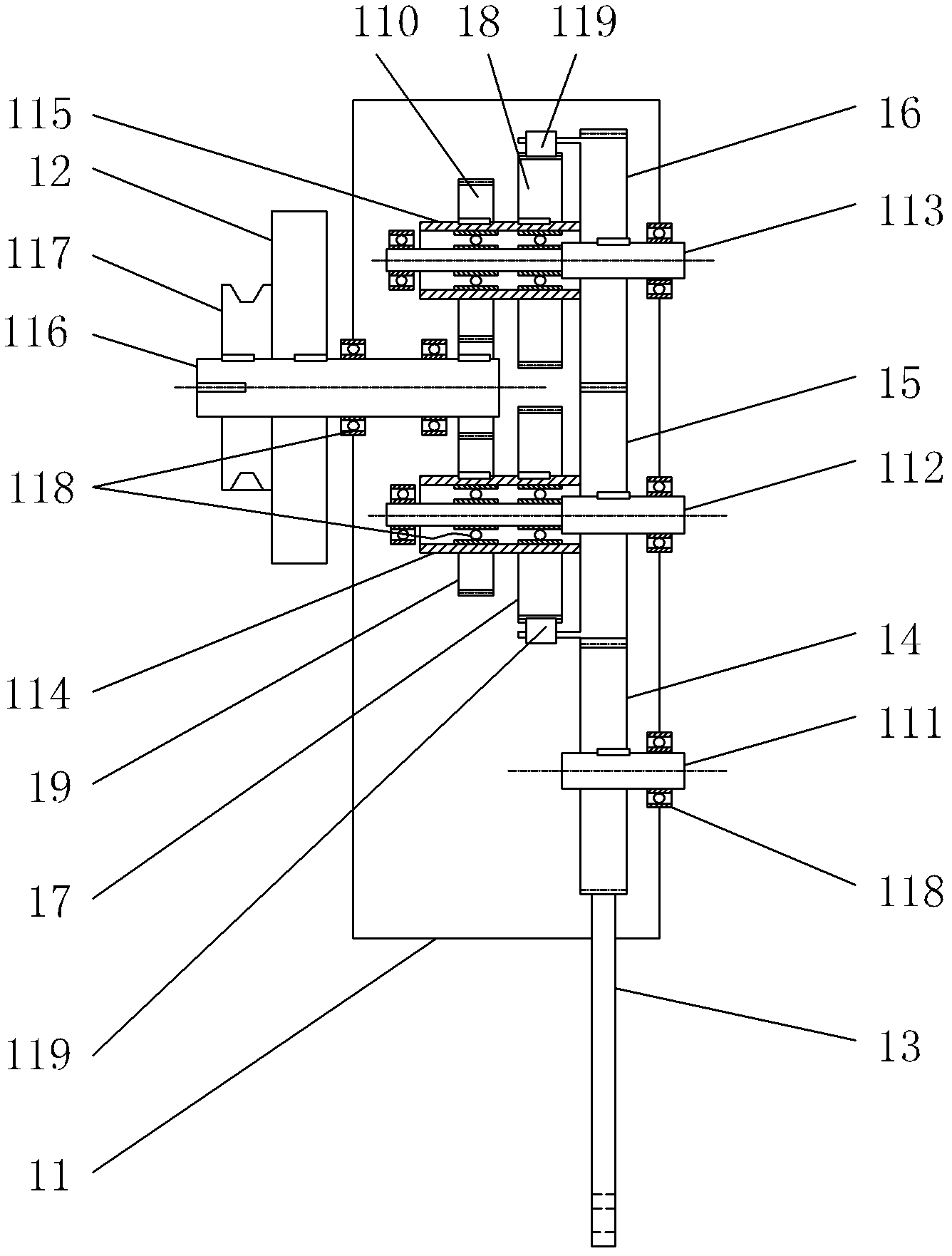

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 :

[0017] A mechanical motion conversion device, in which three shafts 111, 2 112, and 113 are arranged parallel to each other in sequence in a box body 11, and three shafts 111, 2 112, and 3 113 are arranged respectively. The first-stage gears 14, 15, and 16 with equal pitch circles meshing with each other, the shaft one 111 or the first-stage gear 14 on the shaft one 111 are fixedly connected with the rocker arm 13, and the shaft two 112 and the shaft three 113 are respectively sleeved with hollow gears. The shafts 114, 115 and the hollow shafts 114, 115 are respectively fixedly connected with secondary gears 17, 18 whose pitch circle diameters are smaller than the pitch circle diameters of the primary gears 15, 16 and which rotate coaxially with the secondary gears 17, 18. For the three-stage gears 19, 110 whose indexing circle d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com