Corner sewing method of two-needle sewing machine

A sewing machine and corner technology, applied in sewing machine control devices, sewing machine components, sewing machine needle holders, etc., can solve the problems of limited market application and the inability to adjust the needle distance D1 at will, and achieve the effect of flexible corners

Active Publication Date: 2017-07-21

ZHEJIANG DUMA SEWING MACHINE

View PDF8 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, the needle distance D1 cannot be adjusted arbitrarily according to the needs of users

The market application of this method is extremely limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

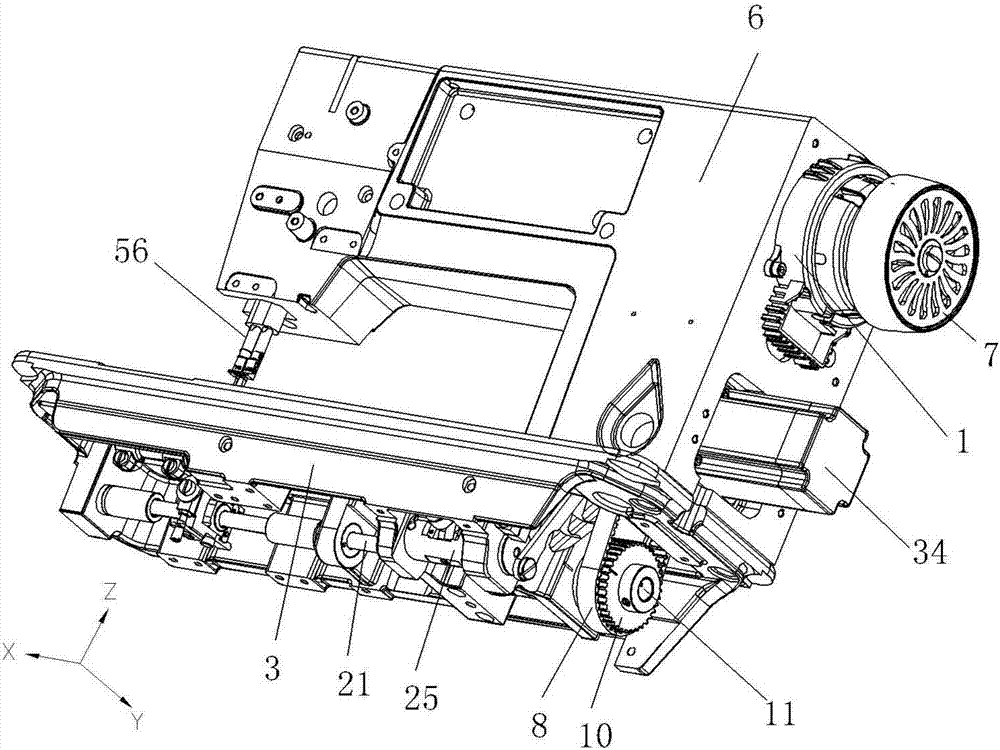

[0092] This embodiment is basically the same as Embodiment 1, the difference lies in the connection structure between the stepping motor 34 and the slot seat 25: the end of the slot seat 25 is provided with a large gear, and the stepping motor 34 is provided with a pinion gear, through synchronous Belt or gear meshing mode transmission, realize fine adjustment of slot seat 25 position by stepper motor 34.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

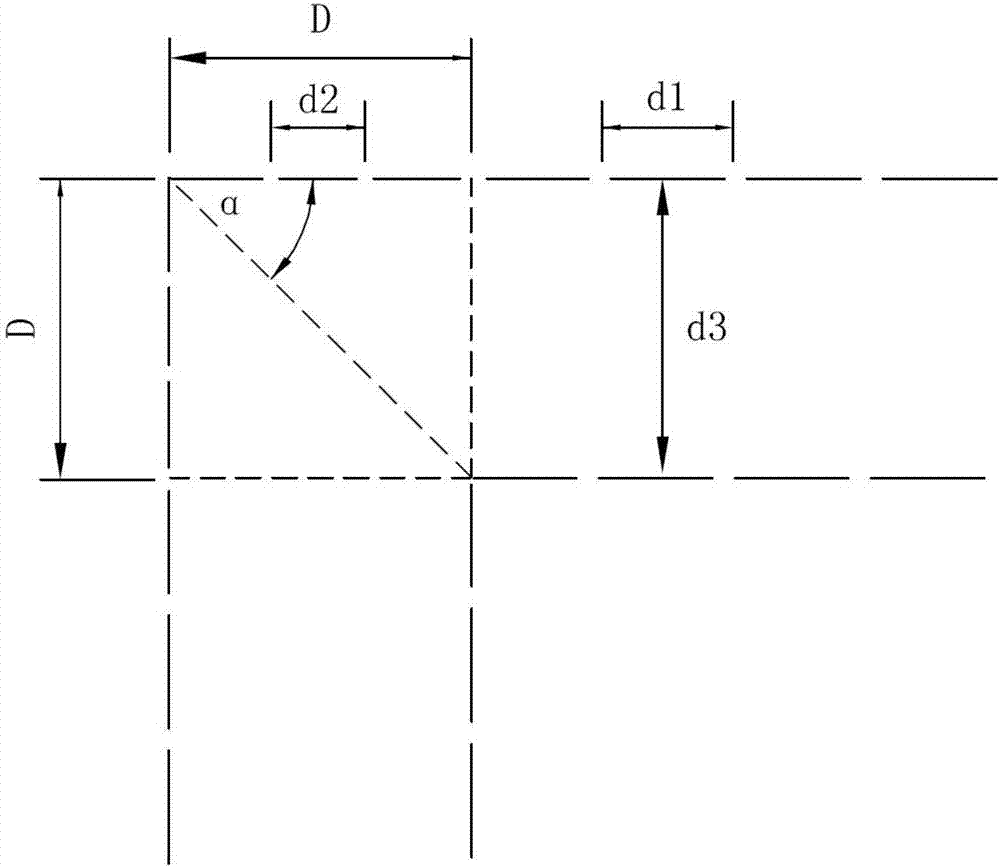

The invention relates to the technical field of two-needle machines and especially relates to a corner sewing method of a two-needle sewing machine. The method comprises the steps that (1) the degree number beta of a corner and a turning direction of a thread track are input in an operation interface when turning is needed during sewing; (2) a control unit computes a walking length D of a walking needle rod; (3) a starting instruction is input, the control unit makes the two needle rods separated automatically, the separated needle rod stops working, the working needle rod keeps on walking for the length D, and then the machine needle is paused, and a press foot is lifted; (4) a sewing fabric is rotated by the angle beta with the working needle rod as the center, the staring instruction is input, the press foot moves downwards and presses the fabric, and the working needle rod keeps on walking for the length D; and (5) the control unit resets the two needle rods, and the needle spacing is automatically recovered to D1. According to the invention, the walking length D of the working needle rod as well as the walking needle spacing D2 and the needle number X within the walking length D of the walking needle rod can be computed automatically according to a current needle spacing D1 and a turning angle, so corner turning becomes more flexible and the method has market application prospect.

Description

technical field [0001] The technical field of double-needle sewing machines of the present invention particularly refers to a corner sewing method of a double-needle sewing machine. Background technique [0002] Double-needle machine is a sewing machine with two machine needles. The stitches it sew are two parallel and parallel sutures. Due to the high efficiency of double-needles and the parallel and beautiful appearance of double-needles, it is widely used. In the mass-produced garment industry. [0003] At present, the curved corner sewing of double-needle machines is very difficult and difficult to master, and the left needle bar or the right needle bar can only be separated by manually pulling the switch; and the most difficult thing during the curved corner sewing is to ensure the rotation of the sewing material before and after The number of needles moved by a single needle bar is strictly consistent, and even skilled workers often make mistakes, resulting in rework,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D05B19/14D05B55/16D05B69/10

CPCD05B19/14D05B55/16D05B69/10D05D2207/05

Inventor 韩小辉

Owner ZHEJIANG DUMA SEWING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com