Production process of sliced type centrifugal cast iron piston ring

A centrifugal cast iron and production process technology, applied in the field of piston rings, can solve the problems of poor metallographic structure, great influence on piston ring quality, easy ring breakage, etc., and achieve the effects of low cost, high production efficiency and stable elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

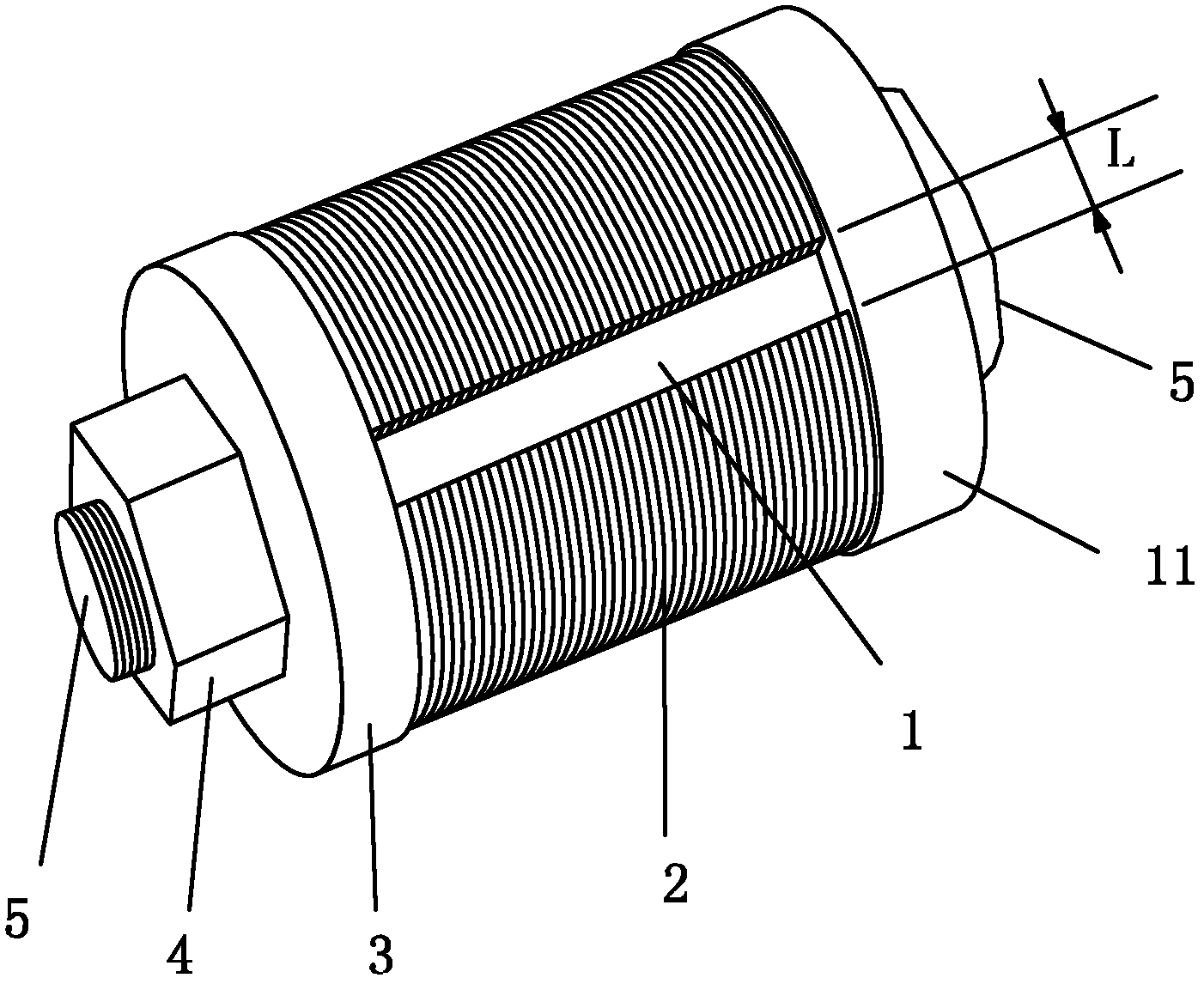

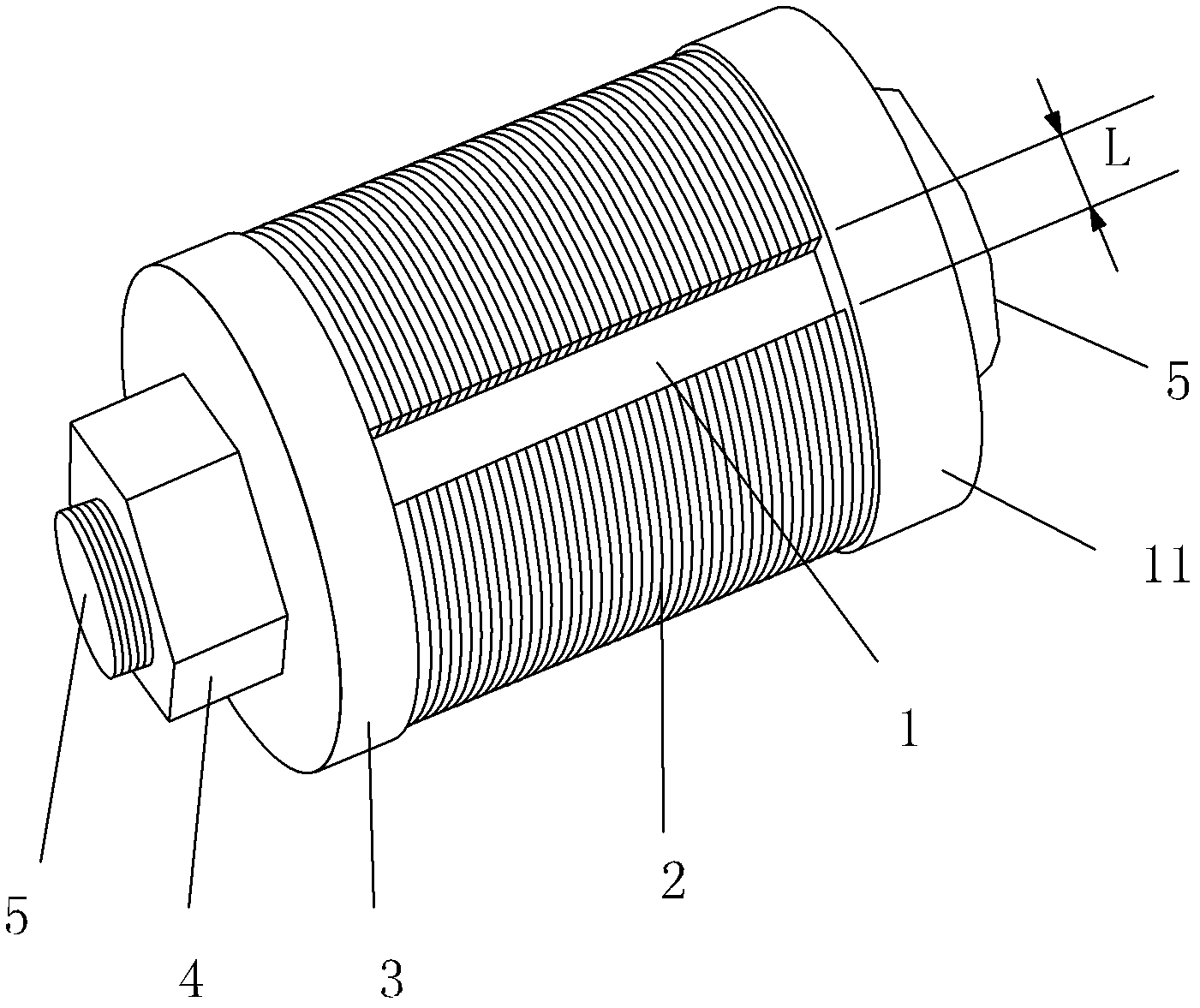

[0017] The present invention will be further described below with specific embodiment in conjunction with accompanying drawing, see figure 1 :

[0018] The production process of the slice type centrifugal cast iron piston ring includes the following steps:

[0019] (1) Casting the cylinder blank of the piston ring, centrifugally pouring the cylinder blank on the centrifugal casting machine;

[0020] (2) Carry out the outer circle and the inner circle of the cylinder blank according to the size of the inner and outer circles of the piston ring;

[0021] (3) Slice the inner and outer cylinder blanks according to the thickness of the piston ring to form rings;

[0022] (4) on the special-purpose opening machine tool for piston rings, the circular ring made in step (3) is opened to form piston ring semi-finished products 2 by the piston ring size required by the cylinder bore;

[0023] (5) Set the piston ring semi-finished product 2 after the opening in step (4) on the oval out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com