Water-based one-coating UV-cured epoxy acrylate coating and preparation method thereof

A technology of epoxy acrylate and epoxy acrylic acid, which is applied in the field of coatings, can solve the problems of volatile organic compound emissions, poor impact resistance, poor flexibility, etc., to improve adhesion and mechanical properties, and fully cross-link and cure the coating film , Improve the effect of light curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

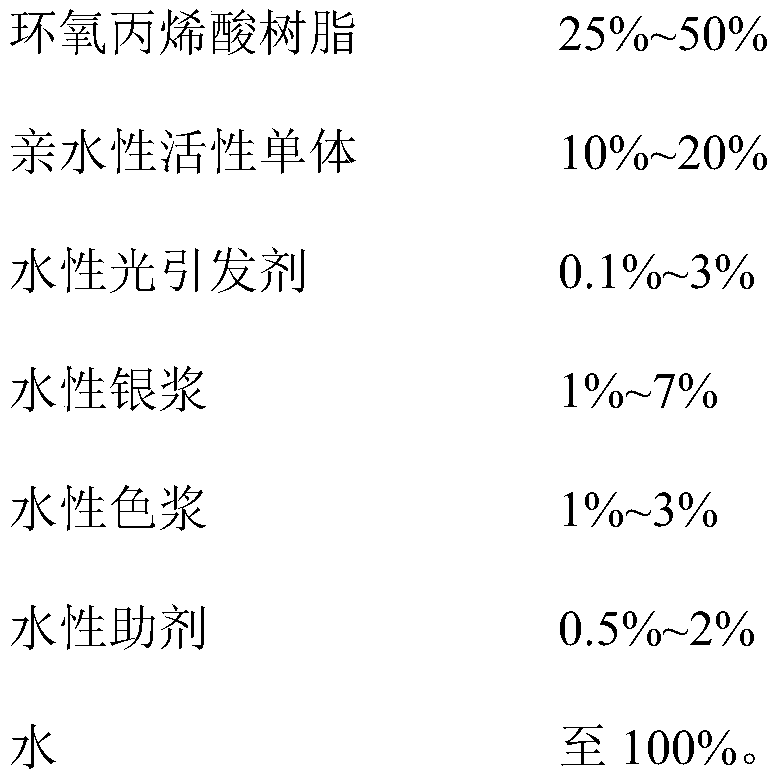

[0030] A kind of water-based one coating UV curing epoxy acrylate paint of the present embodiment comprises following components by mass parts:

[0031]

[0032]

[0033] The epoxy acrylic resin of this example is prepared by the following method: heat and stir 100 parts by mass of E-51 epoxy resin to 50°C, then add 5 parts by mass of acrylic acid, 0.05 parts by mass of acrylate quaternary ammonium salt catalyst and 0.05 parts by mass of Inhibitor N-nitrosobenzene aluminum salt, and then heated to 90 ° C for 8 hours to obtain epoxy acrylic resin.

[0034] Described acrylate quaternary ammonium salt, it is prepared by following method:

[0035] Dissolve 90 parts by mass of acrylic acid in ethyl acetate, then dropwise add 1 part by mass of epoxypropyltrimethylammonium chloride (dissolved with 10 parts by mass of acrylic acid in advance), remove ethyl acetate after the reaction is complete, and obtain acrylate quaternary ammonium salt. The usage amount of acrylate quatern...

Embodiment 2

[0039] A kind of water-based one coating UV curing epoxy acrylate paint of the present embodiment comprises following components by mass parts:

[0040]

[0041] The epoxy acrylic resin of this example is prepared by the following method: heat and stir 100 parts by mass of E-44 epoxy resin to 90°C, then add 70 parts by mass of acrylic acid, 3 parts by mass of acrylate quaternary ammonium salt catalyst and 2 parts by mass of Inhibitor N-nitrosobenzene aluminum salt, and then raise the temperature to 150 ° C for 2 hours to obtain epoxy acrylic resin.

[0042] Described acrylate quaternary ammonium salt, it is prepared by following method:

[0043]Dissolve 80 parts by mass of acrylic acid in ethyl acetate, then dropwise add 15 parts by mass of epoxypropyltrimethylammonium chloride (dissolved with 20 parts by mass of acrylic acid in advance), and cool down in an ice-water bath during the reaction to prevent gelation. After the reaction is complete, ethyl acetate is removed to ...

Embodiment 3

[0047] A kind of water-based one coating UV curing epoxy acrylate paint of the present embodiment comprises following components by mass parts:

[0048]

[0049] The epoxy acrylic resin of this example is prepared by the following method: heat and stir 100 parts by mass of F-51 epoxy resin to 70°C, then add 20 parts by mass of acrylic acid, 1 part by mass of acrylate quaternary ammonium salt catalyst and 0.2 parts by mass of Inhibitor N-nitrosobenzene aluminum salt, and then raise the temperature to 100 ° C for 4 hours to obtain epoxy acrylic resin.

[0050] Described acrylate quaternary ammonium salt, it is prepared by following method:

[0051] Dissolve 90 parts by mass of acrylic acid in ethyl acetate, then dropwise add 5 parts by mass of epoxypropyltrimethylammonium chloride (dissolved with 10 parts by mass of acrylic acid in advance), remove ethyl acetate after the reaction is complete, and obtain acrylate quaternary ammonium salt. The usage amount of acrylate quater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com