A kind of environmental protection chain extender and preparation method thereof

A technology of chain extender and small molecule chain extender is applied in the field of environmental protection chain extender and its preparation, and achieves the effects of appropriate curing time, appropriate operating time, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

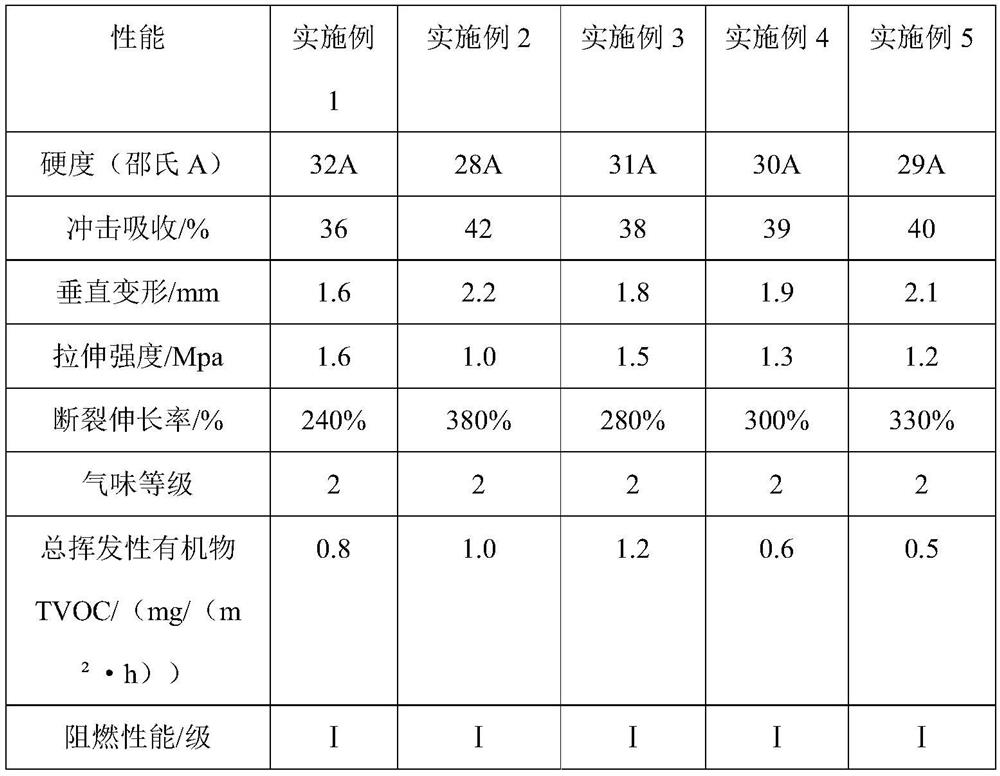

Examples

Embodiment 1

[0023] Example 1 An environmentally friendly chain extender, its preparation raw materials include the following components by weight percentage: small molecule chain extender 6%, modified polyether 7%, amino-terminated polyether 8%, small molecular weight polyoxypropylene glycol 40%, polyol chain extender 20%, aliphatic diamine 7%, aromatic diamine 12%.

[0024] The molecular weight of the low molecular weight polyoxypropylene diol is 400-1000 Daltons.

[0025] The molecular weight of the modified polyether is less than 400 Daltons. The modified polyether uses polyether polyol as a raw material, and diphenylmethane diisocyanate (MDI) as a chain extender to form a hydroxyl mole Hydroxyl-terminated modified polyether with a mole ratio of 2:1 isocyanate group.

[0026] The small molecule chain extender is selected from 1,3-propanediol. The polyol is polyoxypropylene triol. The aromatic diamine is 3,5-dimethylthiotoluenediamine (DMTDA). The aliphatic diamine is an alicyclic d...

Embodiment 2

[0032] Embodiment 2 An environmentally friendly chain extender, its preparation raw materials include the following components by weight percentage: small molecule chain extender 5%, modified polyether 8%, amino-terminated polyether 5%, small molecular weight polyoxypropylene glycol 45%, polyol chain extender 22%, aliphatic diamine 5%, aromatic diamine 10%.

[0033] The molecular weight of the low molecular weight polyoxypropylene diol is 400-1000 Daltons.

[0034] The molecular weight of the modified polyether is less than 400 Daltons. The modified polyether uses polyether polyol as a raw material, and diphenylmethane diisocyanate (MDI) as a chain extender to form a hydroxyl mole The hydroxyl-terminated modified polyether with a molar ratio of isocyanate group of 2:1 is mainly used to improve cohesion and strength and improve physical properties relative to polyether.

[0035] The small molecule chain extender is a mixture of 1,4-butanediol and 1,6-hexanediol. The polyol is...

Embodiment 3

[0041] Example 3 An environmentally friendly chain extender, its preparation raw materials include the following ingredients in weight percentage: small molecule chain extender 8%, modified polyether 6%, amino-terminated polyether 6%, small molecular weight polyoxypropylene glycol 35%, polyol chain extender 19%, aliphatic diamine 8%, aromatic diamine 18%.

[0042] The molecular weight of the low molecular weight polyoxypropylene diol is 400-1000 Daltons.

[0043]The molecular weight of the modified polyether is less than 400 Daltons. The modified polyether uses polyether polyol as a raw material, and diphenylmethane diisocyanate (MDI) as a chain extender to form a hydroxyl mole Hydroxyl-terminated modified polyether with a mole ratio of 2:1 isocyanate group.

[0044] The small molecule chain extender is resorcinol dihydroxyethyl ether. The polyol is polyoxypropylene triol. The aromatic diamine is 3,5-diethyltoluenediamine (DETDA). The aliphatic diamine is an alicyclic diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com