Bio-membrane reactor for treating low-carbon-nitrogen-ratio wastewater and refractory organic matters

A technology of refractory organic matter and biofilm reactor, which is used in water pollutants, anaerobic digestion treatment, biological water/sewage treatment, etc. It can solve the problems of high water temperature requirements and low impact load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In conjunction with the accompanying drawings, the description is as follows:

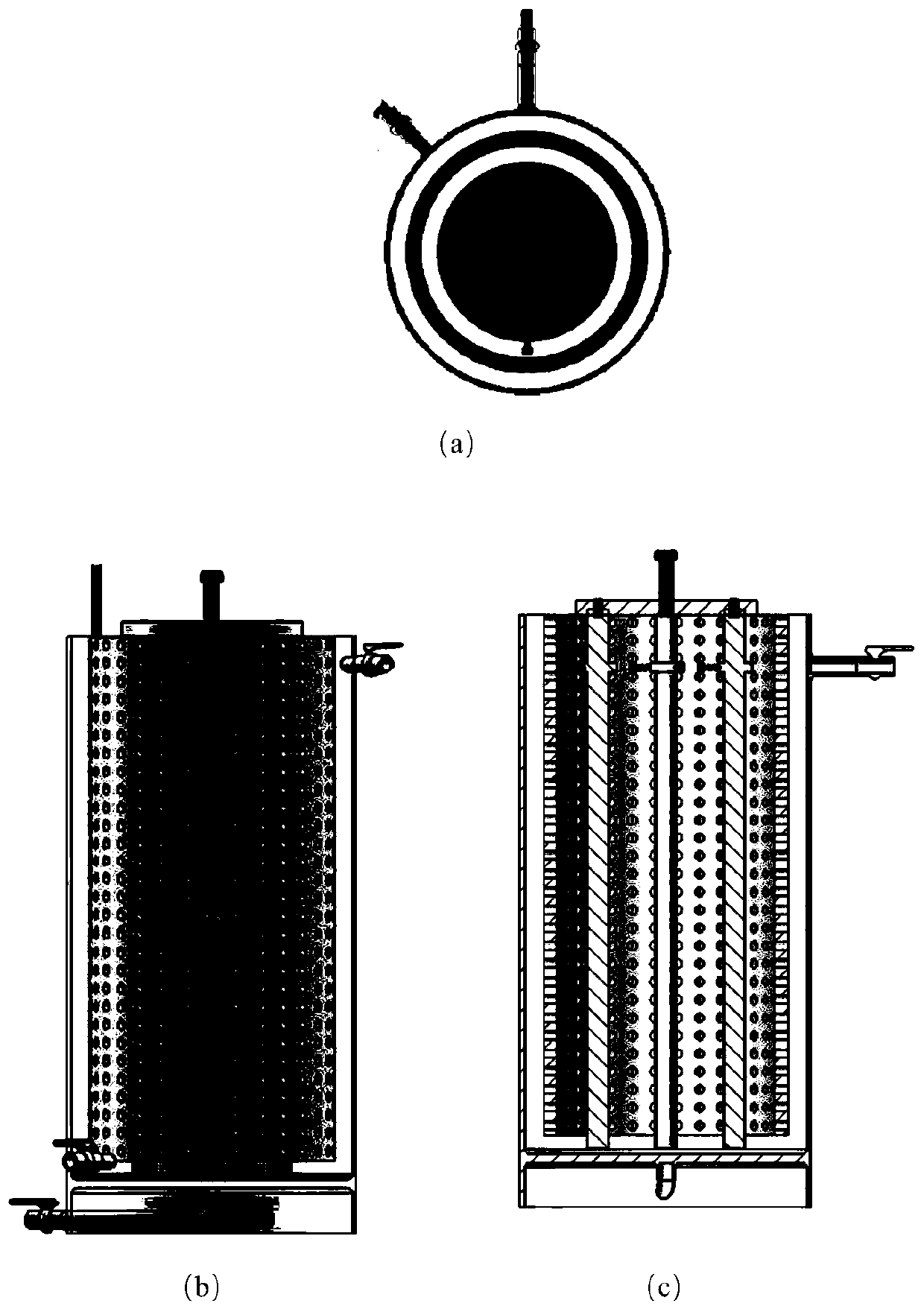

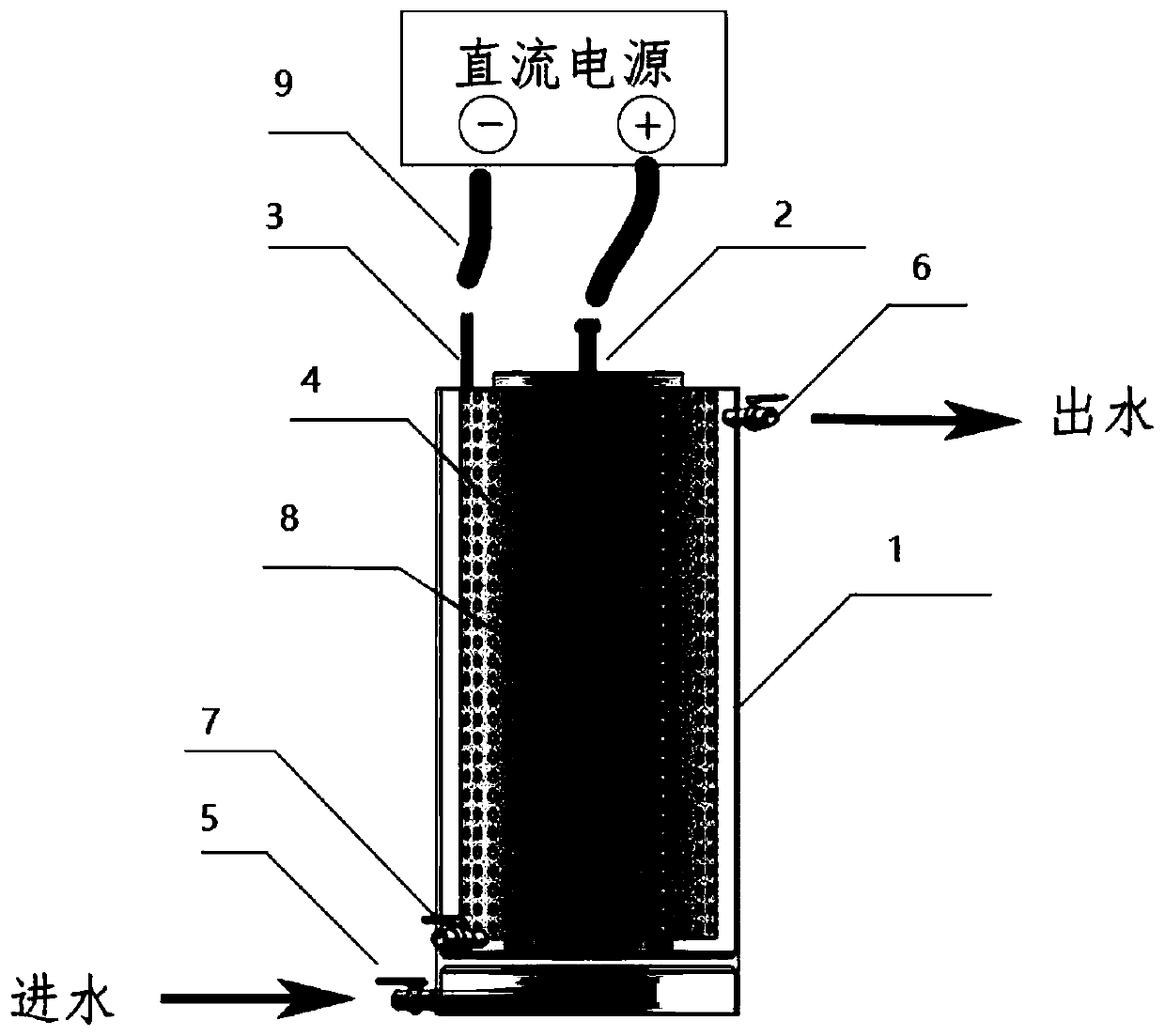

[0029] Such as figure 1 and 2 Shown, a kind of three-dimensional electrode biofilm reactor, it comprises a cylindrical casing (1), is provided with water inlet (5) below the side, and cathode (3) is hollow cylinder band hole structure, is connected to DC power supply On the negative electrode of the cathode, the anode is placed in the middle of the hollow cylinder of the cathode, and the anode is a disc with a screw hole structure. The anode is connected to the positive pole of the DC power supply, iron carbon is filled between the anode and the cathode, and a certain amount of sulfur autotrophic microorganisms domesticated in the laboratory is inoculated to form a biofilm. Activated carbon is filled between the cathode and the casing. The drain port is set above the shell, and the hydraulic retention time is adjusted through the peristaltic pump at the water inlet.

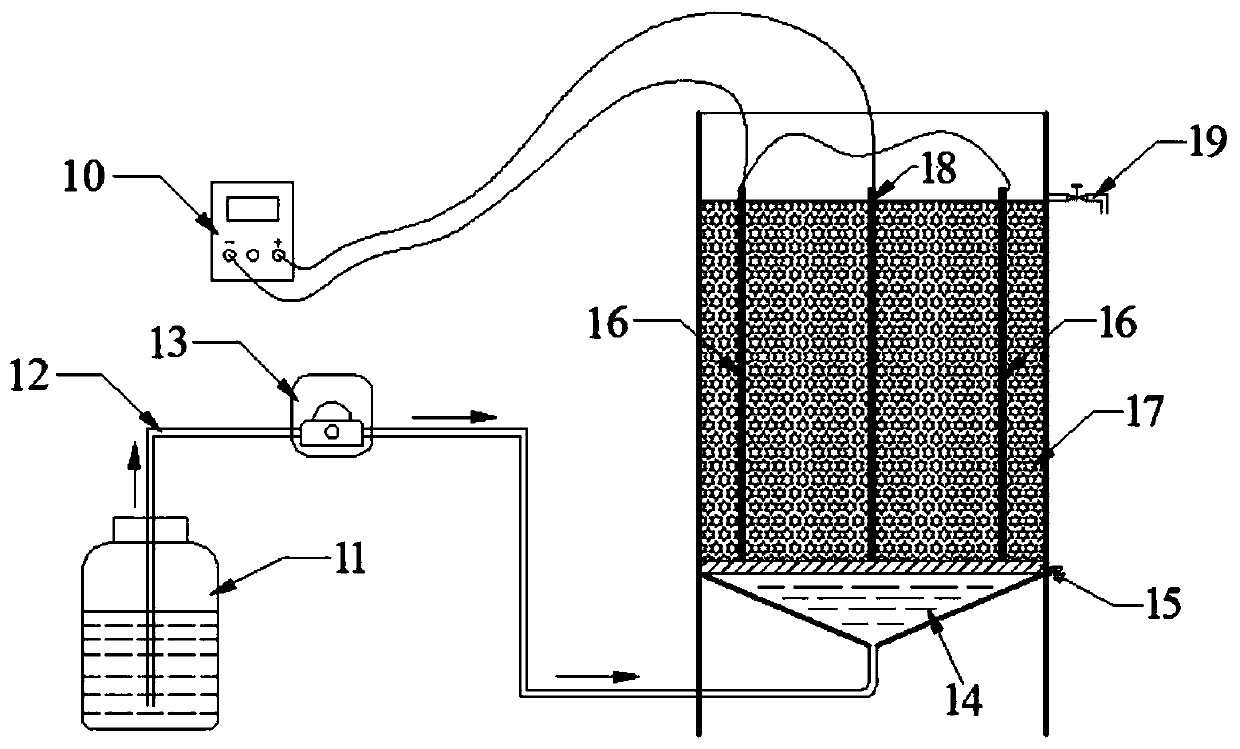

[0030] image 3 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com