Polymer microcatheter with regular arrangement of two-dimensional sheet-like fillers and preparation method thereof

A flake filler and micro-catheter technology, applied in the field of micro-catheter products, can solve the problems such as the inability to maximize the enhancement effect of the compressive performance and barrier properties of the polymer tube, the limited performance of the polymer micro-catheter, and the inability to be used as an industrialized product, etc. The effect of long service life, easy operation and extended penetration path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a polymer microcatheter in which two-dimensional sheet-like fillers are regularly arranged in a microcosm, comprising the following process steps:

[0036] (1) Mix the polyolefin elastomer material grains and the two-dimensional sheet-shaped filler montmorillonite as the raw material of the polymer microcatheter uniformly according to the weight ratio of 1:0.02, and set aside;

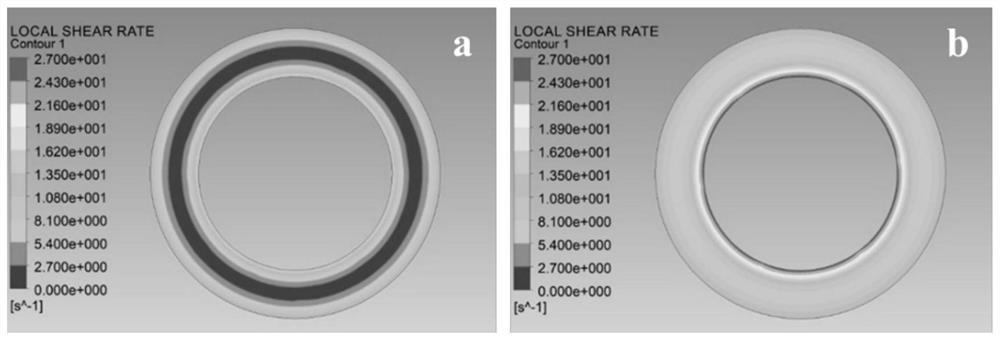

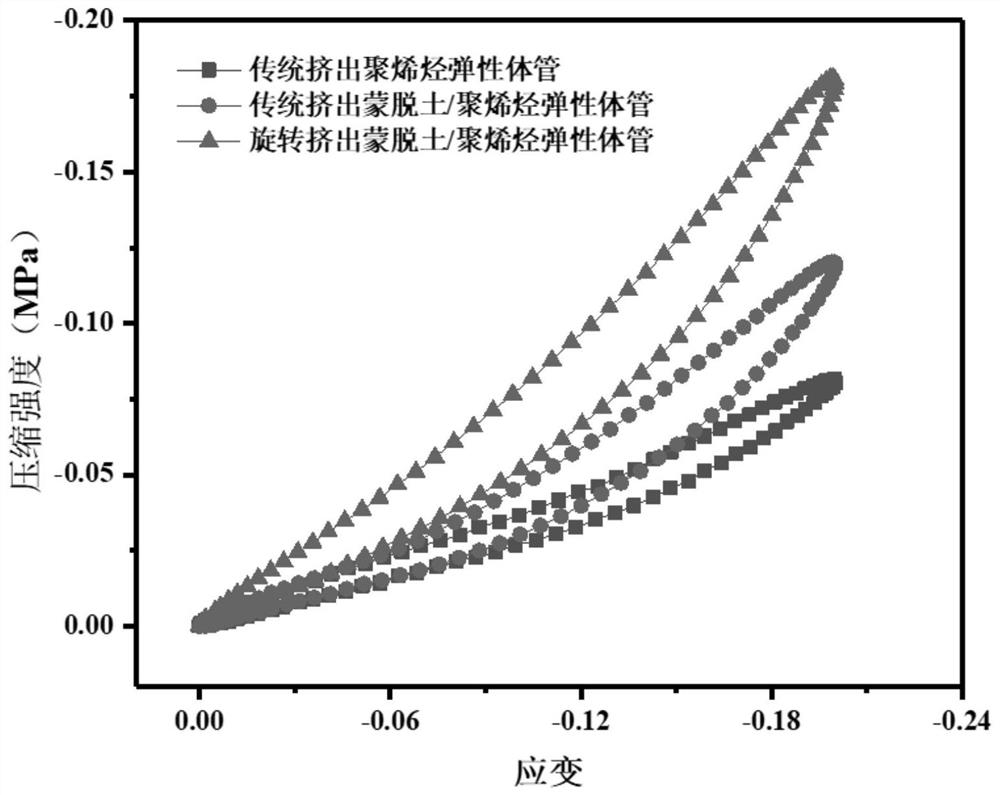

[0037] (2) Extrude the mixture obtained in step (1) through a high-performance polymer pipe preparation device with application number 200810045785.9 to obtain a polymer microcatheter in which two-dimensional sheet-like fillers are arranged in a regular microcosmic manner ; Wherein the mandrel and the die rotate in opposite directions at the same speed. The process parameters are as follows: the opening angle of the bell mouth of the sizing sleeve of the cooling and shaping mechanism is 15°, and the length is 13cm. Vacuum sizing and spraying on the outer wall of the pipe ar...

Embodiment 2

[0040] A method for preparing a polymer microcatheter in which two-dimensional sheet-like fillers are regularly arranged in a microcosm, comprising the following process steps:

[0041] (1) Mix the polyurethane pellets and the two-dimensional flake filler graphene as the raw material of the polymer microcatheter uniformly according to the weight ratio of 1:0.03, and set aside;

[0042] (2) Extrude the mixture obtained in step (1) through a high-performance polymer pipe preparation device with application number 200810045785.9 to obtain a polymer microcatheter in which two-dimensional sheet-like fillers are arranged in a regular microcosmic manner ; Wherein the mandrel and the die rotate in opposite directions at the same speed, and the process parameters are as follows: the opening angle of the bell mouth of the sizing sleeve of the cooling and shaping mechanism is 14°, and the length is 13cm. Vacuum sizing and spraying on the outer wall of the pipe, The temperature of the spr...

Embodiment 3

[0045] A method for preparing a polymer microcatheter in which two-dimensional sheet-like fillers are regularly arranged in a microcosm, comprising the following process steps:

[0046] (1) Mix the polyethylene material granules and the two-dimensional flake filler molybdenum disulfide as the raw material of the polymer microcatheter evenly according to the weight ratio of 1:0.2, and set aside;

[0047] (2) Extrude the mixture obtained in step (1) through a high-performance polymer pipe preparation device with application number 200810045785.9 to obtain a polymer microcatheter in which two-dimensional sheet-like fillers are arranged in a regular microcosmic manner ; Wherein the mandrel and the die are rotating in opposite directions at the same speed. The process parameters are as follows: the bell opening angle of the sizing sleeve of the cooling and shaping mechanism is 17°, and the length is 14cm. Vacuum sizing and spraying on the outer wall of the pipe are adopted. The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com