Pressing production line and production process of upper cover plate of cooler shell for 5G base station

A production process and radiator technology, applied in the field of communications, can solve the problems of long cooling time, large force on the fins, and difficulty in recovery, and achieve the effect of reducing the floor space and cooling time, and increasing the heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

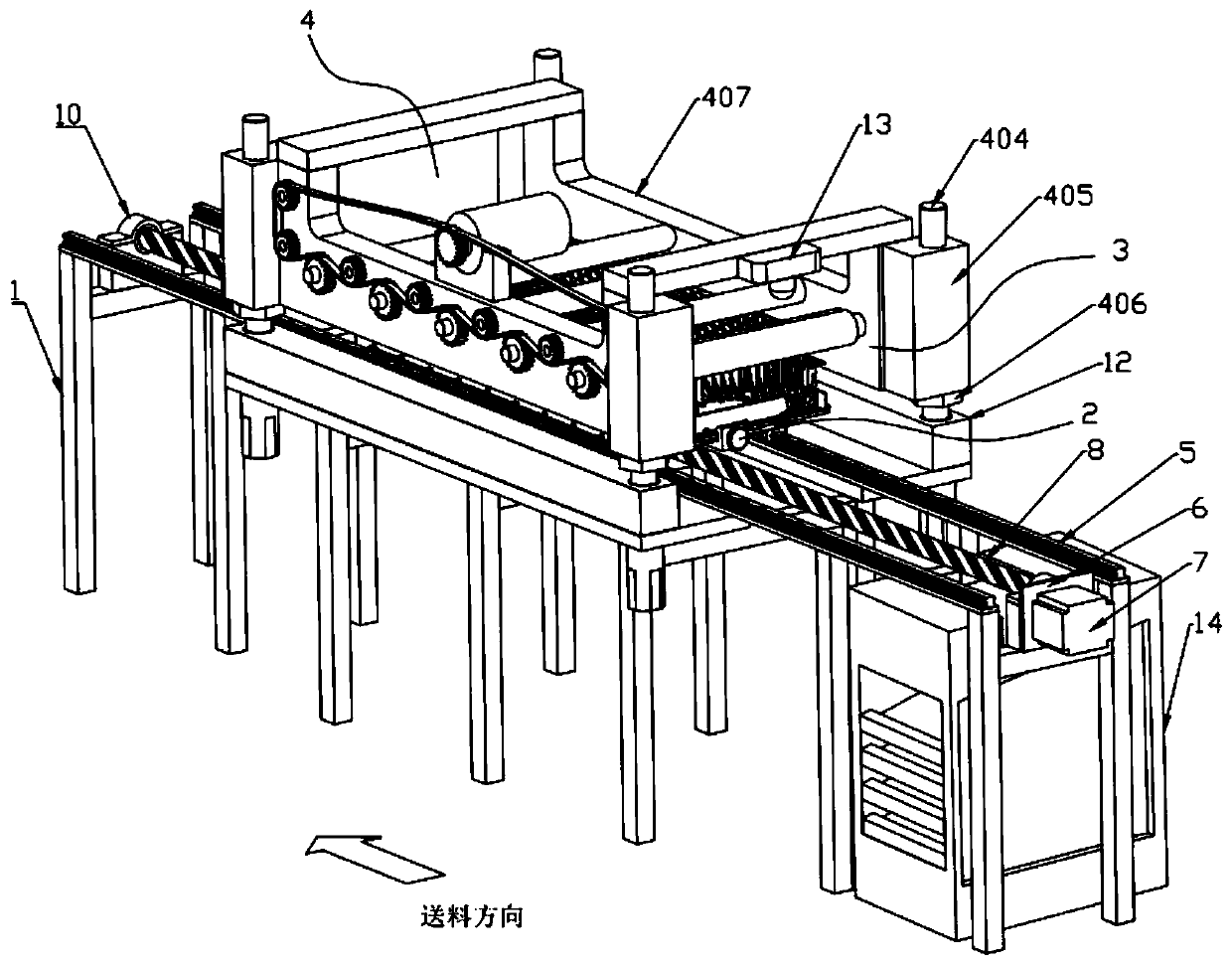

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

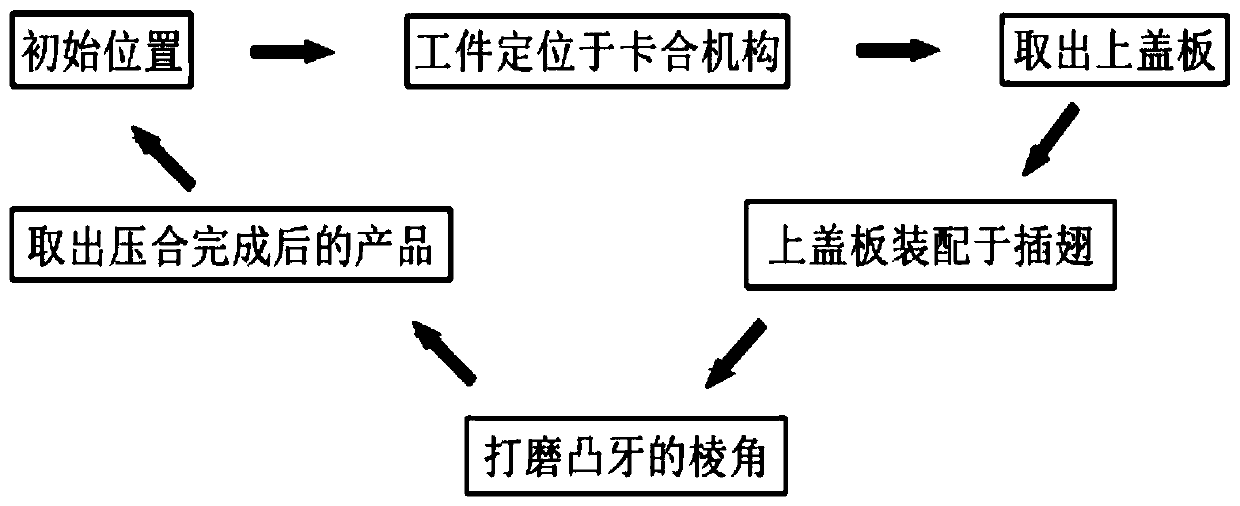

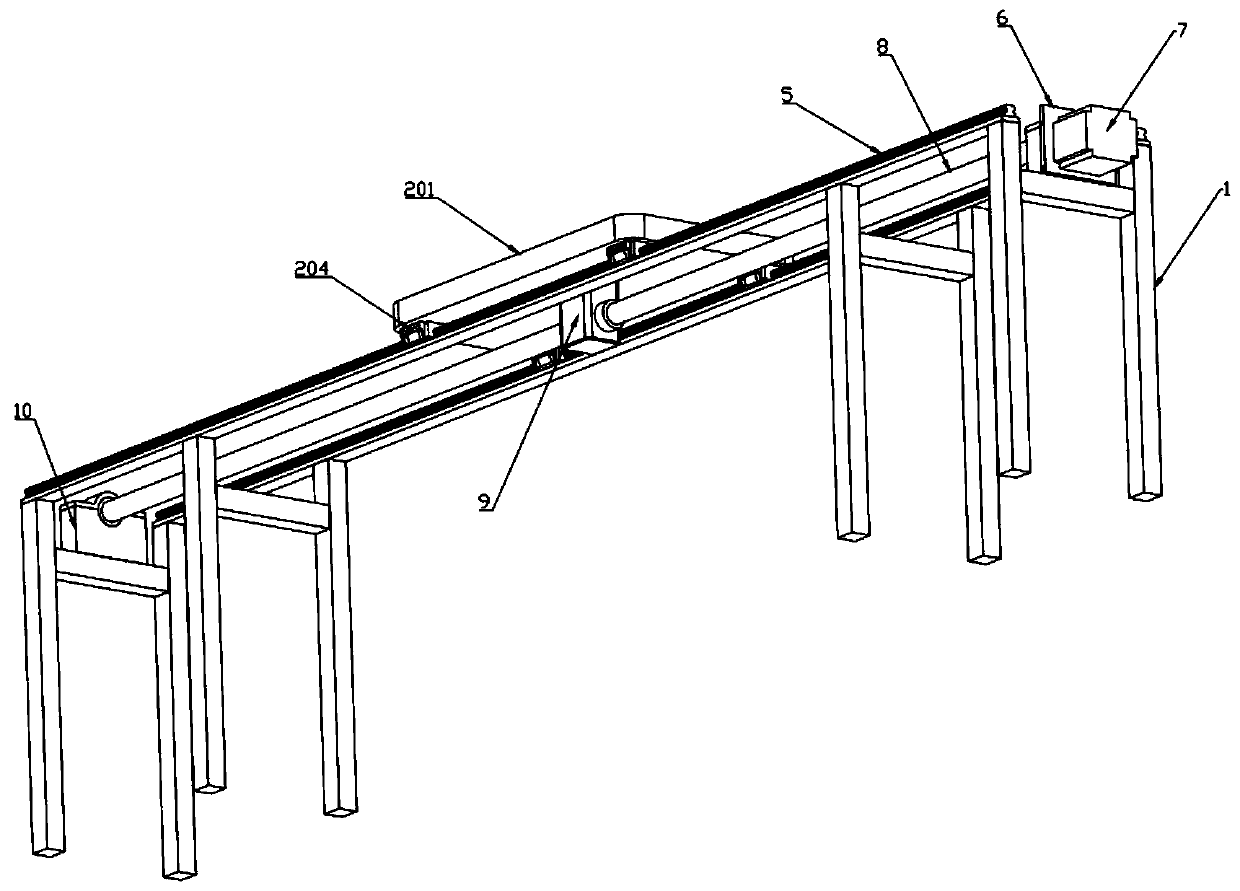

[0034] like Figure 1 to Figure 9 As shown, a pressing production process of the upper cover of the radiator shell for 5G base stations is implemented based on the pressing production line of the upper cover. The production line includes a snapping mechanism 2, a grinding mechanism 3 and a rolling mechanism 4 , including the following steps,

[0035] Step 1: first move the engaging mechanism 2 from the base frame 1 to the feeding position, then place the base 301 with the insert fins 302 on the engaging mechanism 2 and position it;

[0036] Step 2: Take out the upper cover plate 11 with a suitable size from the placement cavity 143 in the loading rack 14;

[0037] Step 3: Install the taken-out upper cover plate 11 on the insert fin through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com