Preparation of conductive manganese-titanium lithium ion sieve/graphene composite hydrogel and application of conductive manganese-titanium lithium ion sieve/graphene composite hydrogel in extraction of lithium from salt lake brine

A technology of graphene composite and salt lake brine, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. The effect of shortening the time, less corrosion of equipment, and reducing the amount of acid used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

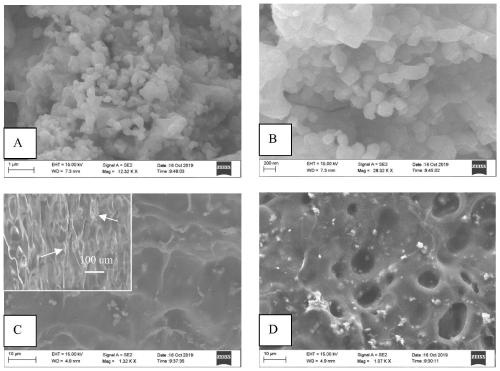

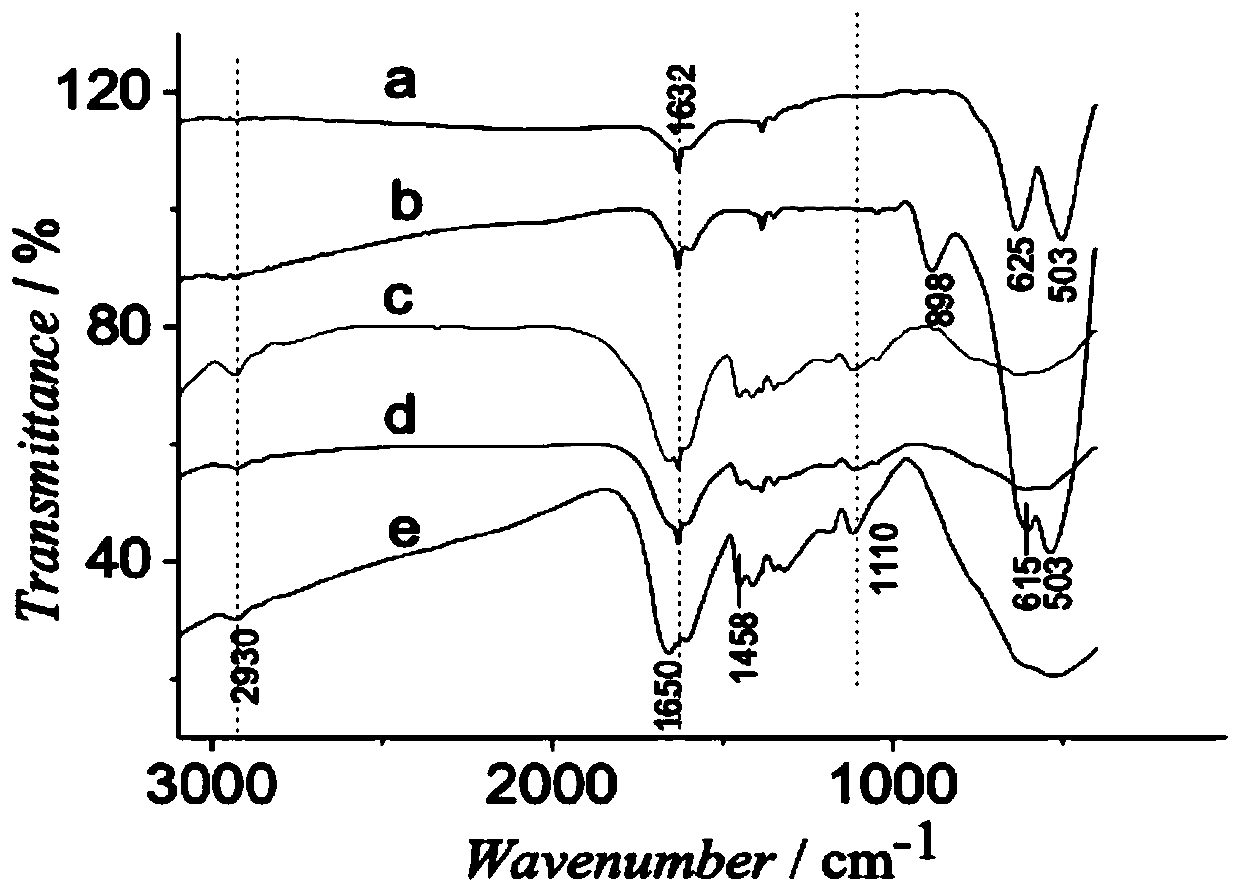

Image

Examples

Embodiment 1

[0044] 1. Preparation of conductive manganese-titanium lithium ion sieve / graphene composite hydrogel (HMnTi / GNs-LIPs)

[0045] (1) Preparation of manganese-titanium lithium ion sieve (HMnTi)

[0046] In 100 mL of 50% ethanol aqueous solution, 1.8 g of lithium acetate was added (solution A). In 100 mL of 90% ethanol aqueous solution, 4.5 g of manganese chloride, 7.5 g of tetrapropyl titanate and 3.5 g of triethanolamine were sequentially added (solution B). Add A dropwise to B, add 2mL, 1M phosphoric acid to form sol solution C. React C at 90°C for 6 hours to form a sol-gel, and the precursor D can be obtained after grinding. D is roasted, firstly temperature programmed at 5 °C / min to 300 °C, and reacted for 10 h; then programmed at 10 °C / min to 700 °C, reacted for 8 h to form a manganese-titanium lithium complex (marked as LiMnTi). The LiMnTi was washed with 5% hydrochloric acid for 6 hours and then dried to form a manganese-titanium lithium ion sieve (HMnTi) for future use...

Embodiment 2

[0056] 1. Preparation of conductive manganese-titanium lithium ion sieve / graphene composite hydrogel (HMnTi / GNs-LIPs)

[0057] (1) Preparation of manganese-titanium lithium ion sieve (HMnTi)

[0058] In 100 mL of 90% aqueous ethanol, 2 g of lithium chloride was added (solution A). In 100 mL of 90% ethanol aqueous solution, 6 g of manganese carbonate, 17 g of tetrabutyl titanate and 4 g of tartaric acid were sequentially added (solution B). After A was added dropwise to B, 1 mL of 1M hydrochloric acid was added to form sol solution C. React C at 55°C for 10 hours to form a sol-gel, and the precursor D can be obtained after grinding. Roast D, firstly heat up to 380°C at 10°C / min, and react for 15 hours; then heat up to 800°C at 5°C / min, and react for 10 hours to form a manganese-titanium lithium complex (marked as LiMnTi). The LiMnTi was washed with 5% hydrochloric acid for 6 hours and then dried to form a manganese-titanium lithium ion sieve (HMnTi) for future use.

[0059]...

Embodiment 3

[0068] 1. Preparation of conductive manganese-titanium lithium ion sieve / graphene composite hydrogel (HMnTi / GNs-LIPs)

[0069] (1) Preparation of manganese-titanium lithium ion sieve (HMnTi)

[0070] In 100 mL of 60% aqueous ethanol, add 5 g of lithium sulfate (solution A). In 100 mL of 90% ethanol aqueous solution, 5.4 g of manganese carbonate, 5.2 g of tetrapropyl titanate, and 1.8 g of citric acid were sequentially added (solution B). Add A dropwise to B, add 2mL, 1M sulfuric acid catalyst to form sol solution C. React C at 90°C for 3 hours to form a sol-gel, and the precursor D can be obtained after grinding. D is roasted, firstly temperature programmed at 5 °C / min to 300 °C, and reacted for 10 h; then programmed at 10 °C / min to 700 °C, reacted for 8 h to form a manganese-titanium lithium complex (marked as LiMnTi). The LiMnTi was washed with 5% hydrochloric acid for 6 hours and then dried to form a manganese-titanium lithium ion sieve (HMnTi) for future use.

[0071] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com