Online dilute sulfuric acid concentration control device in chlorine drying process based on DCS control system

A control system and drying process technology, applied in the direction of control/regulation system, ratio control, non-electric variable control, etc., can solve the problems of low automation level, reaction lag, dilute sulfuric acid concentration can only rely on manual analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

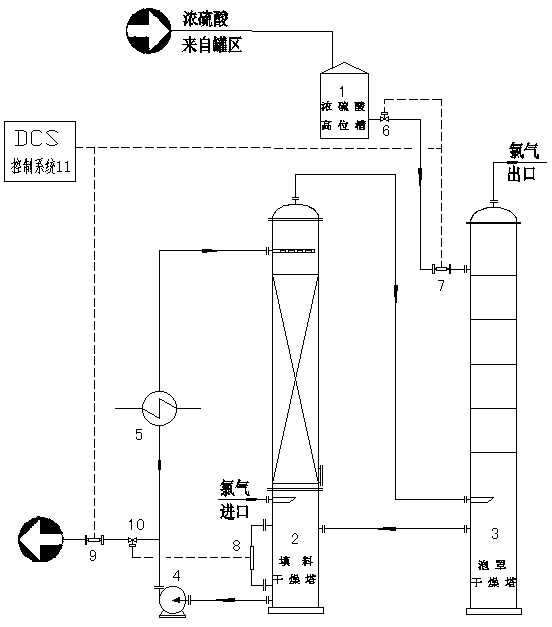

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] see figure 1 , an online control device for the concentration of dilute sulfuric acid in the chlorine drying process based on the DCS control system, which is provided with a concentrated sulfuric acid high-level tank 1; the concentrated sulfuric acid high-level tank 1 is connected with the sulfuric acid output of the sulfuric acid supply process through pipelines, and the concentrated sulfuric acid is regularly replenished. Ensure the supply of sulfuric acid in the concentrated sulfuric acid head tank 1; the concentrated sulfuric acid head tank 1 is connected with the bubble cap drying tower 3 through the lower acid pipeline, and the lower acid pipeline is provided with the higher tank lower acid control valve 6, the lower acid flow meter 7, and the higher level The lower acid control valve 6 and the lower acid flowmeter 7 form the lower acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com