Intelligent composite overwrapped pressure vessel relating to micro-nano sensors and manufacturing method of intelligent composite overwrapped pressure vessel

A technology for pressure vessels and composite materials, applied in the direction of pressure vessels, analysis materials, material resistance, etc., can solve problems such as the influence of composite material pressure vessels on the overall mechanical properties, and achieve simplified wire layout, wide service temperature, and good sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

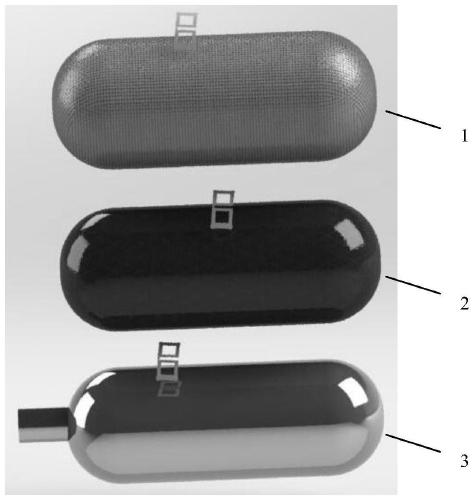

[0027] The composite pressure vessel bottle body includes an aluminum alloy layer, a carbon fiber layer and a glass fiber layer; the aluminum alloy layer is the inner lining of the bottle; the carbon fiber layer, as the middle layer, is the main stress layer; the glass fiber layer is the outermost layer layer protective layer;

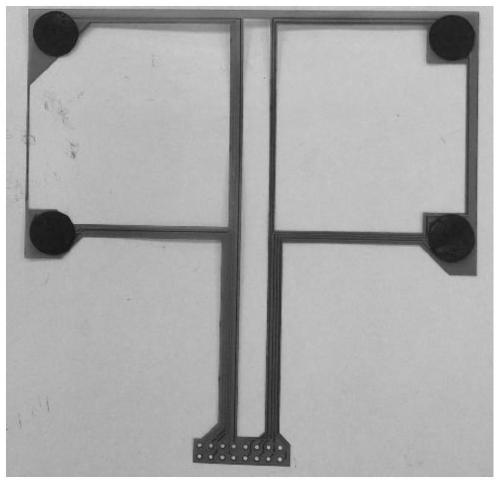

[0028] The flexible sensor array includes micro-nano sensors and flexible printed circuits, such as figure 1 The micro-nano sensor is a circular micro-nano sensor, and the flexible printed circuit includes a substrate, copper foil, an adhesive and a protective film, wherein the substrate and the protective film are composed of polyimide materials, and the micro-nano sensor The flexible sensor array is formed by pasting the adhesive on the corresponding wire electrodes of the flexible printed circuit;

[0029] Multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com