Mounting and pouring process of prefabricated reinforced concrete inspection well

A technology of reinforced concrete and prefabricated assembly, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc. It can solve the problems of inspection well safety, poor concrete waterproof effect, and loose concrete structure. It is not easy to achieve safety. Easy to fall off, not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

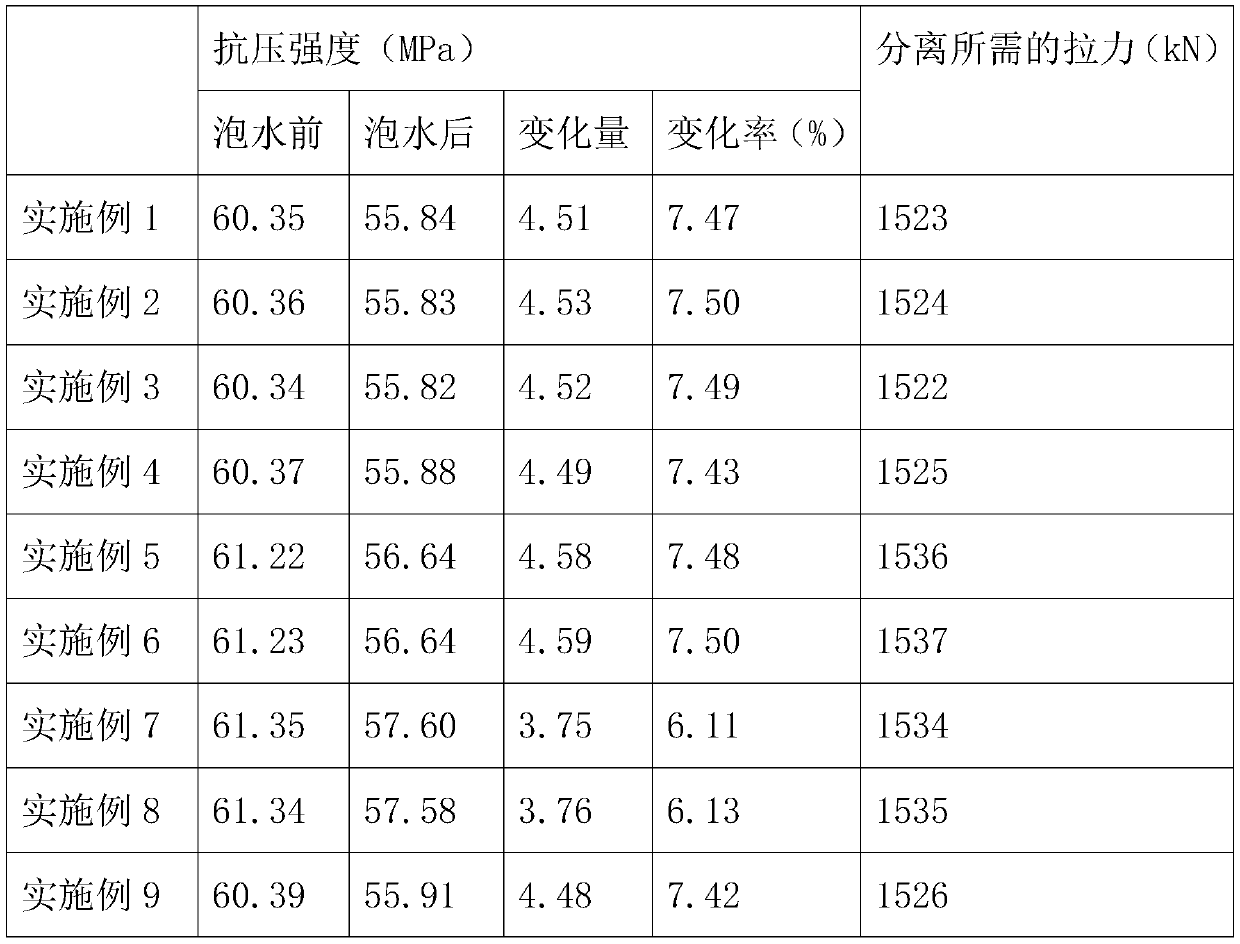

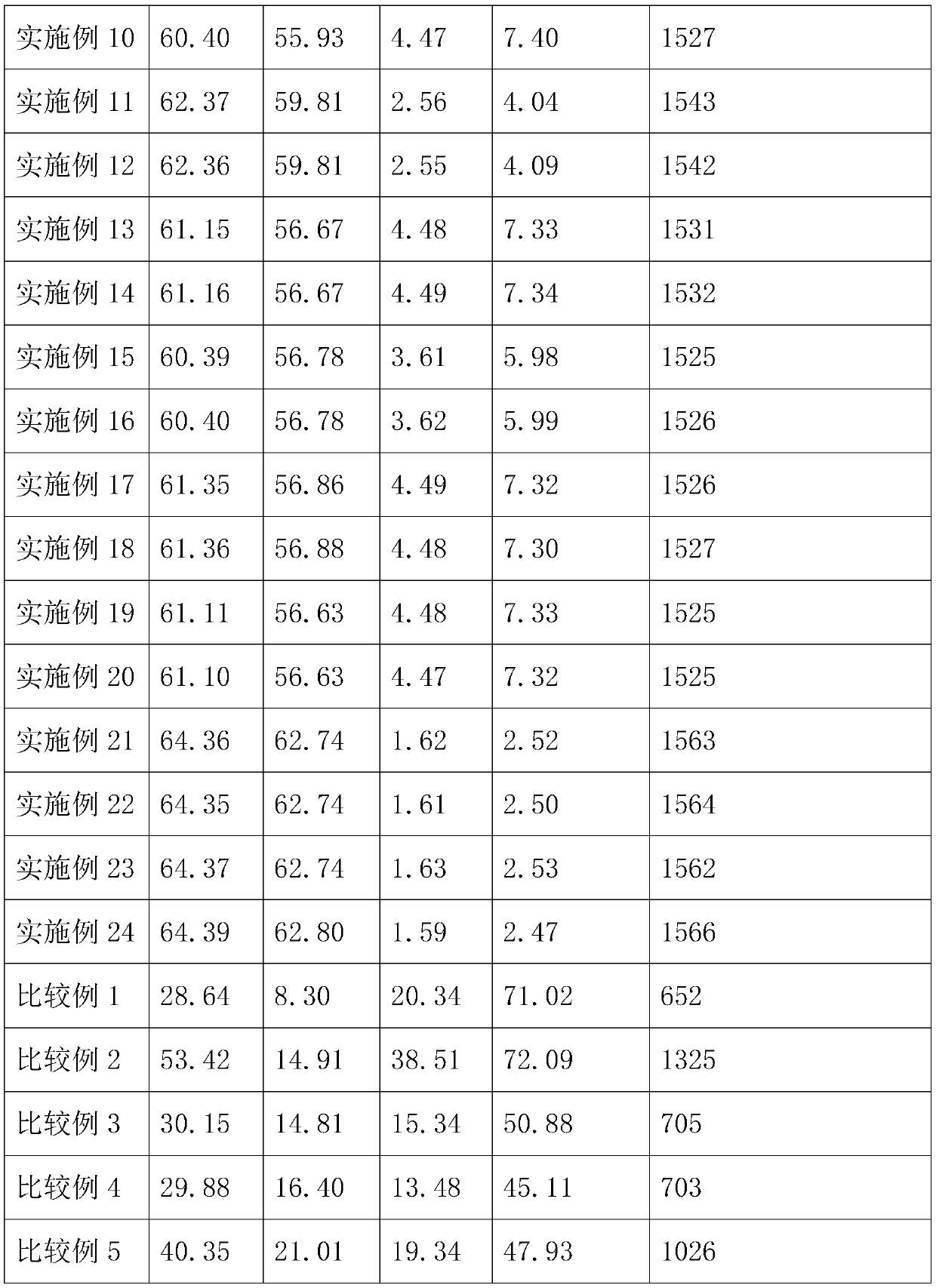

Embodiment 1

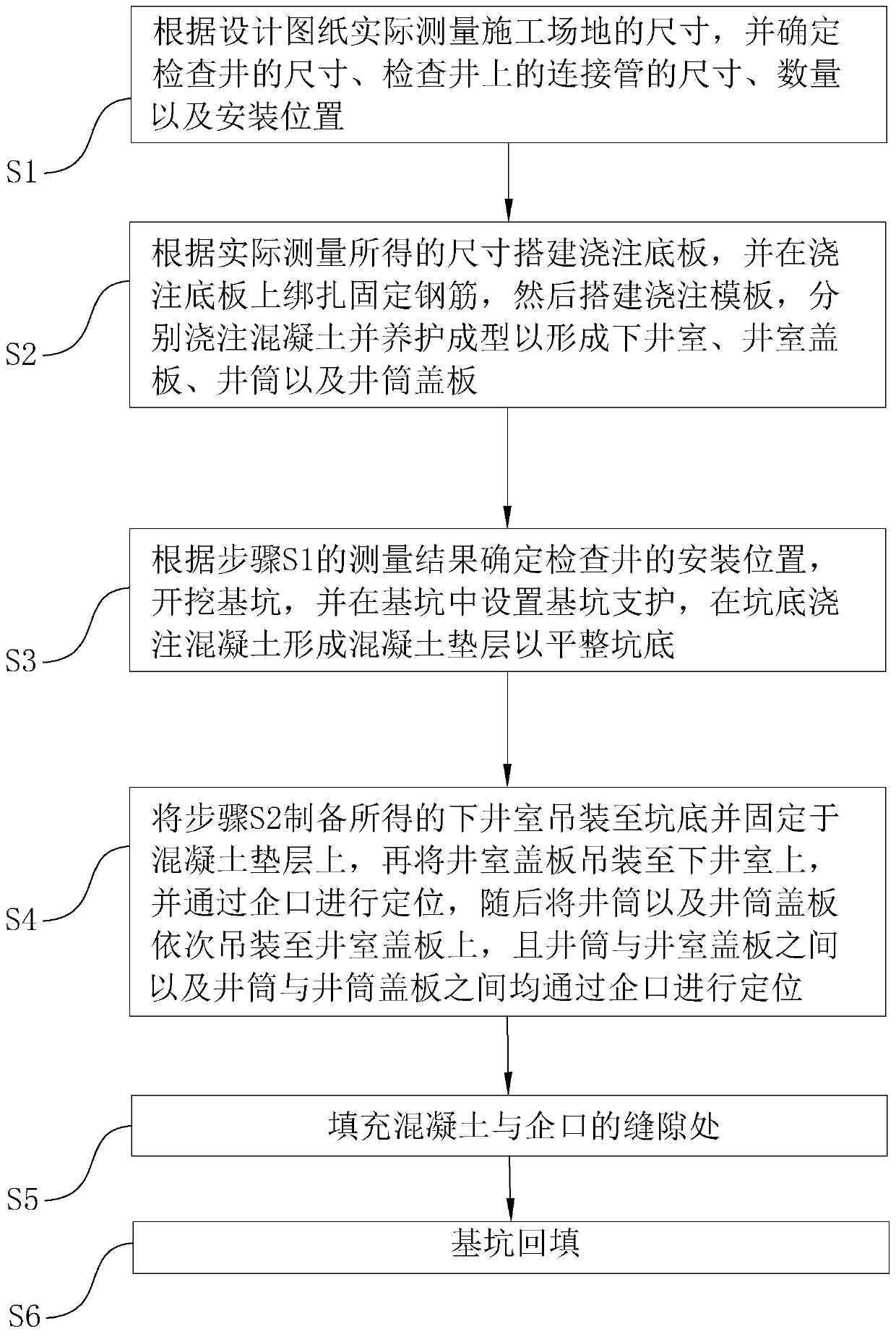

[0071] A prefabricated assembled reinforced concrete inspection well installation pouring process, comprising the following steps:

[0072] S1. Size measurement, as follows:

[0073] Measure the size of the construction site according to the design drawings, determine the size of the inspection well, the size, quantity and installation location of the connecting pipes on the inspection well, mark the installation location, and reserve the location for installing the connecting pipes.

[0074] S2. Inspection well prefabrication, details are as follows:

[0075] Build the pouring base plate according to the actual measured size, and tie and fix the steel bars on the pouring base plate, then build the pouring formwork, pour concrete respectively and cure and shape to form the lower well chamber, well chamber cover plate, well shaft and well shaft cover plate, and the curing temperature is controlled as follows: 45°C, the controlled curing time is 15 days.

[0076] Wherein, the ...

Embodiment 2

[0087] The difference with embodiment 1 is:

[0088] The consumption of each component that adds in the step S2 is as follows:

[0089] 15.5kg of water; 65kg of sand; 45kg of stone; 17.5kg of Portland cement; 3kg of paraffin; 2kg of zinc methacrylate; 1kg of casein; 0.3kg of chitin.

Embodiment 3

[0091] The difference with embodiment 1 is:

[0092] The consumption of each component that adds in the step S2 is as follows:

[0093] 13kg of water; 60kg of sand; 50kg of stone; 20kg of Portland cement; 4kg of paraffin; 1.5kg of zinc methacrylate; 0.75kg of casein; 0.2kg of chitin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com