Aluminum alloy for manufacturing vehicle skylight guide rails and production process thereof

A technology of automobile sunroof and production process, which is applied in the field of designing aluminum alloy processing and manufacturing, and can solve the problems of low production line production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

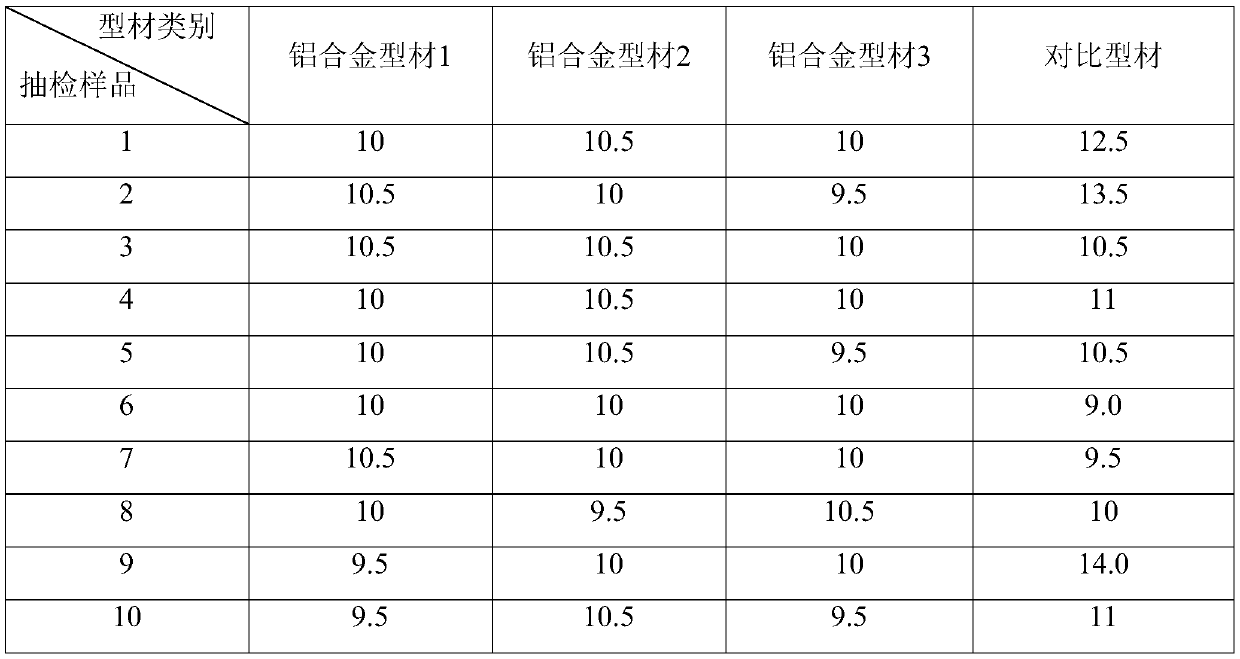

Examples

Embodiment 1

[0020] An aluminum alloy production process for manufacturing automobile sunroof guide rails, comprising the following steps:

[0021] 1) Prepare aluminum alloys according to the following raw materials in parts by weight: Si 0.25%, Fe 0.1%, Cu 0.01%, Mn 0.03%, Mg 0.47%, Zn 0.02%, Ti 0.02%, single impurity ≤ 0.03%, impurity The total is ≤0.10%, and the balance is Al.

[0022] 2) Add the prepared aluminum alloy raw materials into the melting furnace to melt into aluminum liquid, and use electromagnetic stirring equipment to stir evenly; after stirring evenly, use a refining agent to refine and degas, and filter impurities in the aluminum liquid through a ceramic filter plate, and then The molten aluminum is cast into an aluminum alloy ingot. Among them, the purpose of electromagnetic stirring is to enhance the uniformity of the overall stirring, to avoid the uneven distribution of magnesium in the high-magnesium aluminum alloy, and the phenomenon of uneven hardness and mechani...

Embodiment 2

[0028] An aluminum alloy production process for manufacturing automobile sunroof guide rails, comprising the following steps:

[0029] 1) Prepare aluminum alloys according to the following raw materials in parts by weight: Si 0.31%, Fe 0.1%, Cu 0.01%, Mn 0.09%, Mg 0.53%, Zn 0.03%, Ti 0.01%, single impurity ≤ 0.03%, impurity The total is ≤0.10%, and the balance is Al.

[0030] 2) Add the prepared aluminum alloy raw materials into the melting furnace to melt into aluminum liquid, and use electromagnetic stirring equipment to stir evenly; after stirring evenly, use a refining agent to refine and degas, and filter impurities in the aluminum liquid through a ceramic filter plate, and then The molten aluminum is cast into an aluminum alloy ingot. Among them, the purpose of electromagnetic stirring is to enhance the uniformity of the overall stirring, to avoid the uneven distribution of magnesium in the high-magnesium aluminum alloy, and the phenomenon of uneven hardness and mechani...

Embodiment 3

[0036] An aluminum alloy production process for manufacturing automobile sunroof guide rails, comprising the following steps:

[0037] 1) Prepare 6063 aluminum alloy according to the following raw materials in parts by weight: 0.28% Si, 0.09% Fe, 0.02% Cu, 0.05% Mn, 0.50% Mg, 0.02% Zn, 0.015% Ti, single impurity ≤ 0.03%, The total amount of impurities is ≤0.10%, and the balance is Al.

[0038] 2) Add the prepared aluminum alloy raw materials into the melting furnace to melt into aluminum liquid, and use electromagnetic stirring equipment to stir evenly; after stirring evenly, use a refining agent to refine and degas, and filter impurities in the aluminum liquid through a ceramic filter plate, and then The molten aluminum is cast into an aluminum alloy ingot. Among them, the purpose of electromagnetic stirring is to enhance the uniformity of the overall stirring, to avoid the uneven distribution of magnesium in the high-magnesium aluminum alloy, and the phenomenon of uneven ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com