Small horizontal bending machine

A bending machine and horizontal technology, applied in the field of forging machinery, can solve the problems of high equipment manufacturing cost, low work efficiency, complex structure, etc., and achieve the effects of low manufacturing cost, high bending efficiency, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

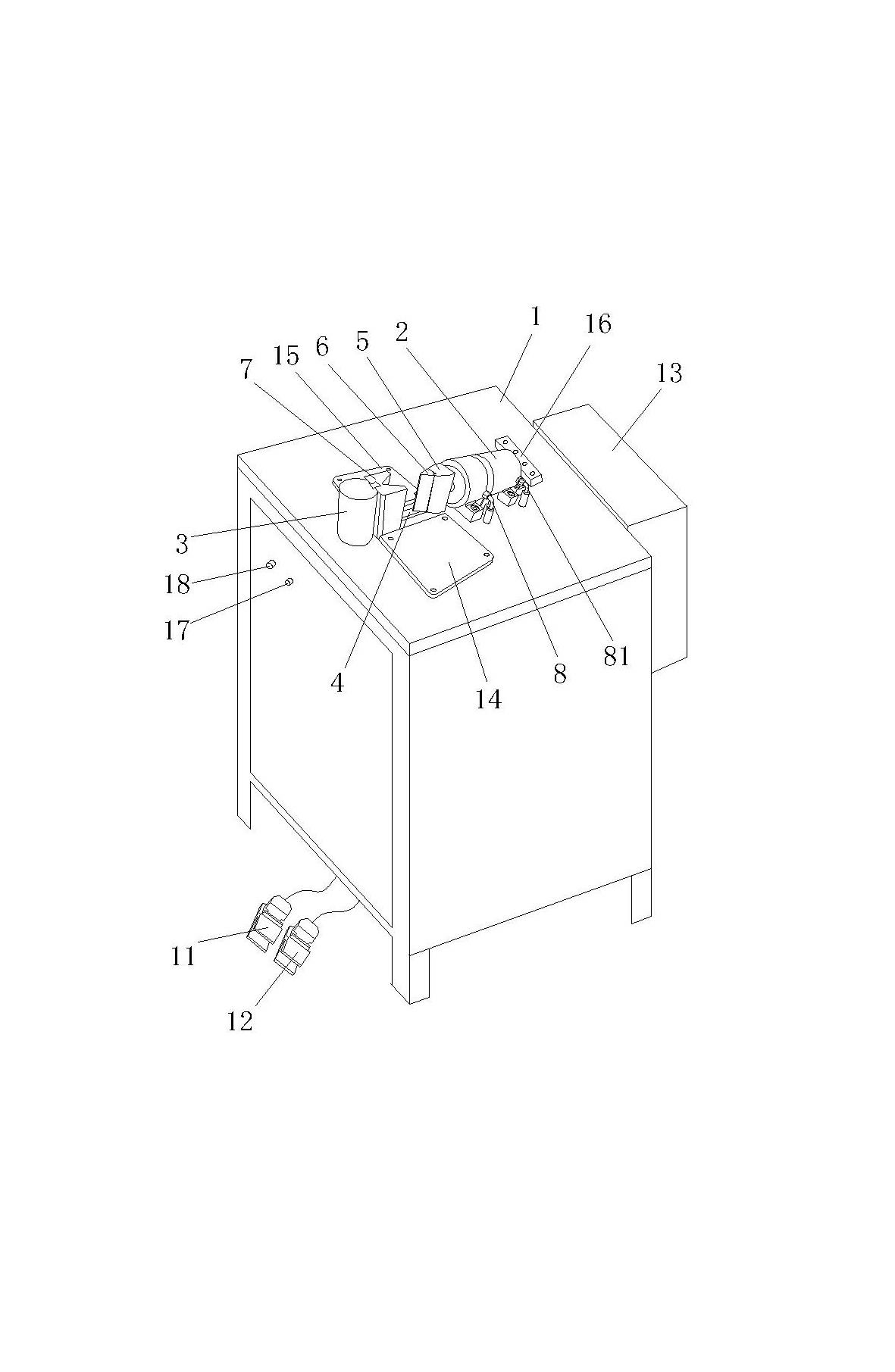

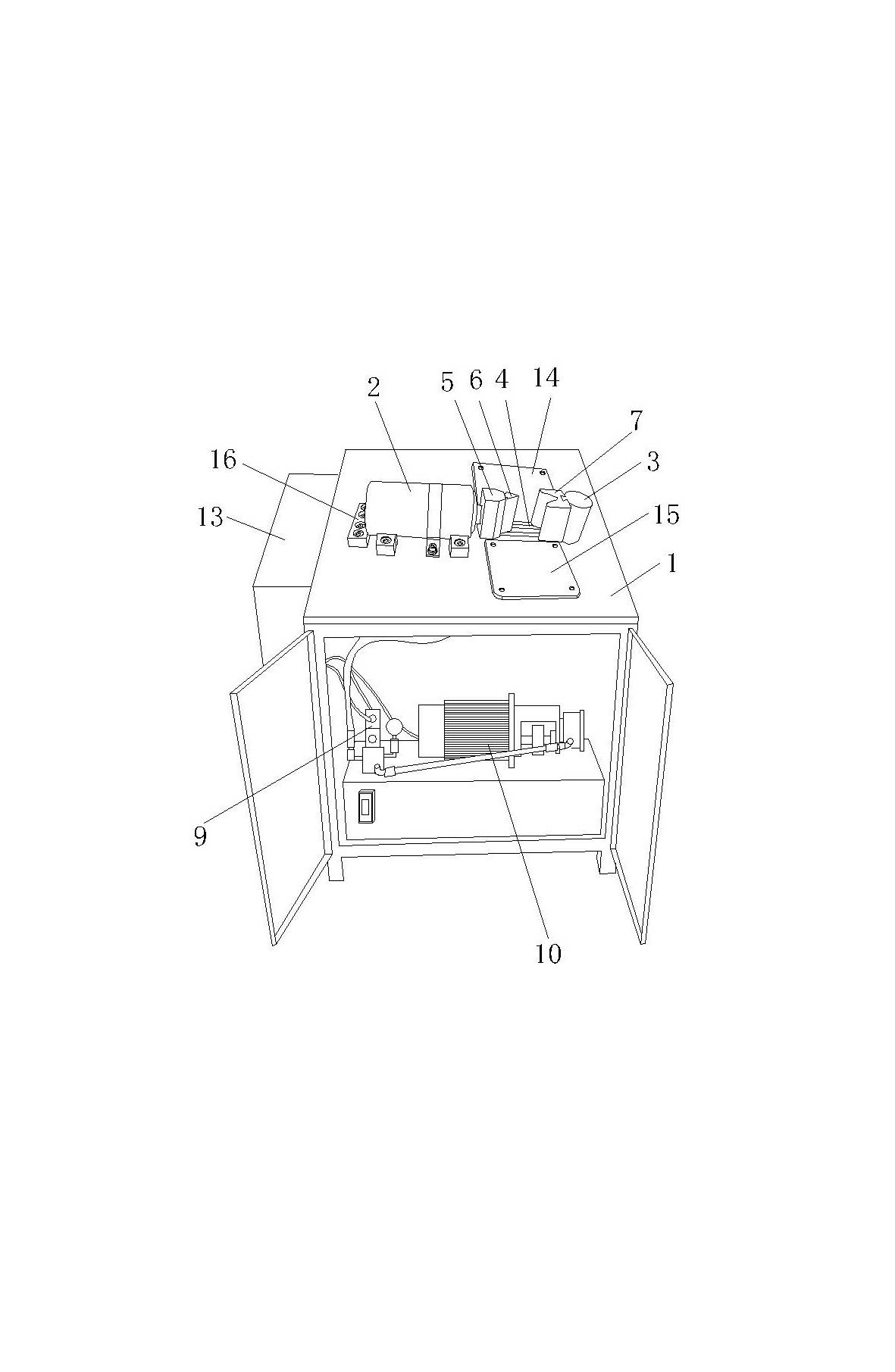

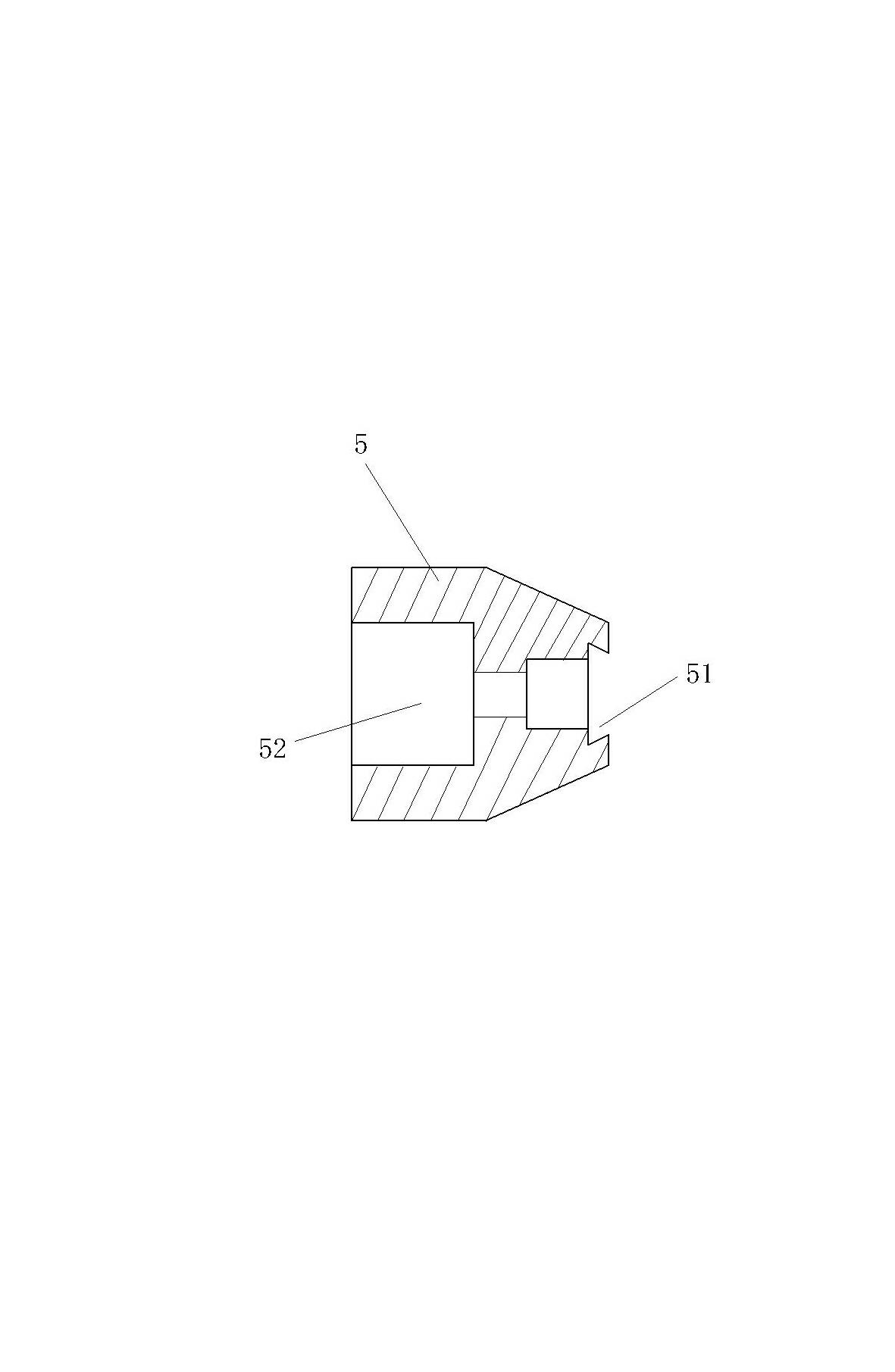

[0025] Figure 1 to Figure 6 As shown, a small horizontal bending machine includes a worktable 1 and an oil cylinder 2. A vertical column 3 is arranged on one side of the worktable 1 along the longitudinal direction, and the other side is fixed to the oil cylinder 2. The vertical column The lower part of 3 passes through the workbench 1 and forms a fixation with the workbench 1; a longitudinal track 4 is fixed on the workbench 1 between the vertical column 3 and the oil cylinder 2, and a slider 5 is fixed on the piston rod 23 of the oil cylinder 2 , the opposite sides of the slider 5 and the vertical column 3 are respectively provided with a vertical dovetail groove 51, 31, the slider 5 is fixed with the piston rod 23 of the oil cylinder 2 through the stepped hole 52 in the middle, and the dovetail groove of the slider 5 51 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com