PC/ABS alloy with excellent damp-heat aging resistance and preparation method thereof

A technology with aging performance and resistance to humidity and heat, which is applied to PC/ABS alloys with excellent resistance to humidity and heat aging and their preparation, and improves the high temperature and humidity resistance of PC/ABS and other polymer materials. Deterioration of wet performance, poor hydrolysis resistance and other problems, to achieve the effect of improving high temperature and high humidity resistance and avoiding hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

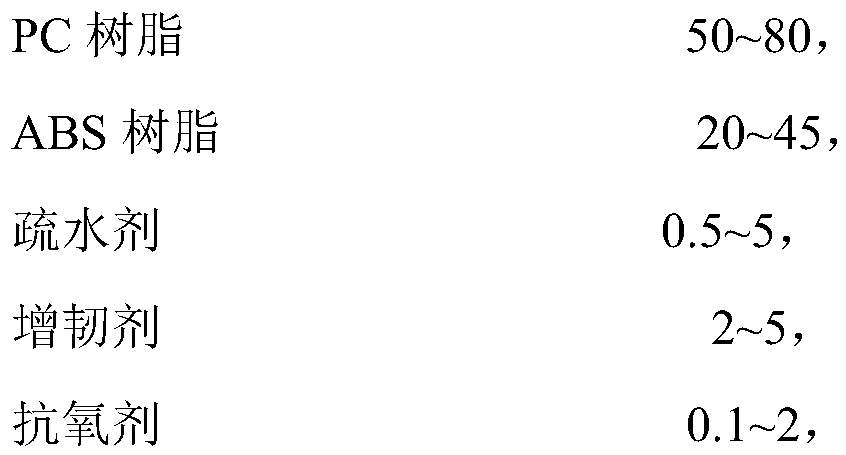

[0030] Embodiments 1-4 provide a method for preparing a PC / ABS alloy with excellent heat and humidity resistance, the content of each component of the alloy in parts by weight is shown in Table 1, and the preparation method is as follows:

[0031] Mix PC, ABS, hydrophobic agent, toughening agent, antioxidant and lubricant in a high-speed mixer (rotating speed: 100-300r / min, mix for 10-30min), and put the mixed material into twin-screw extrusion Machine melt blending extrusion, control the extrusion temperature at 170-230°C, the screw speed at 200-500rpm, the pressure at 2-3MPa, and obtain the product after underwater pelletizing and drying.

Embodiment 5

[0033] The present embodiment provides a kind of preparation method of the PC / ABS alloy excellent in wet heat aging resistance, and this method is 78 weight parts of 7025PJ type PC resin, ABS 3453 resin 20 weight parts, EM500 toughening agent 2 weight parts, CMG9801 0.5 Parts by weight, 0.5 parts by weight of 3-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate antioxidant, 0.5 parts by weight of simethicone lubricant mixed in a high-speed mixer Evenly, put the uniformly mixed material into a twin-screw extruder for melt blending and extrusion, control the extrusion temperature at 170-230°C, the screw speed at 200-500rpm, and the pressure at 2-3MPa. After underwater pelletizing and drying get the product.

Embodiment 6

[0035] This example is basically the same as Example 3, except that the added hydrophobic agent is low-molecular polyvinyl fluoride (molecular weight: 650), thereby preparing a method for preparing a PC / ABS alloy with excellent moisture-heat aging resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com