Treatment method for waste gas generated in process of producing epoxy chloropropane through chloropropene epoxidation

A technology of epichlorohydrin and treatment method, which is applied in the field of petrochemical industry, can solve the problems that cannot meet the requirements of organic tail gas treatment, and achieve the effect of safe and controllable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

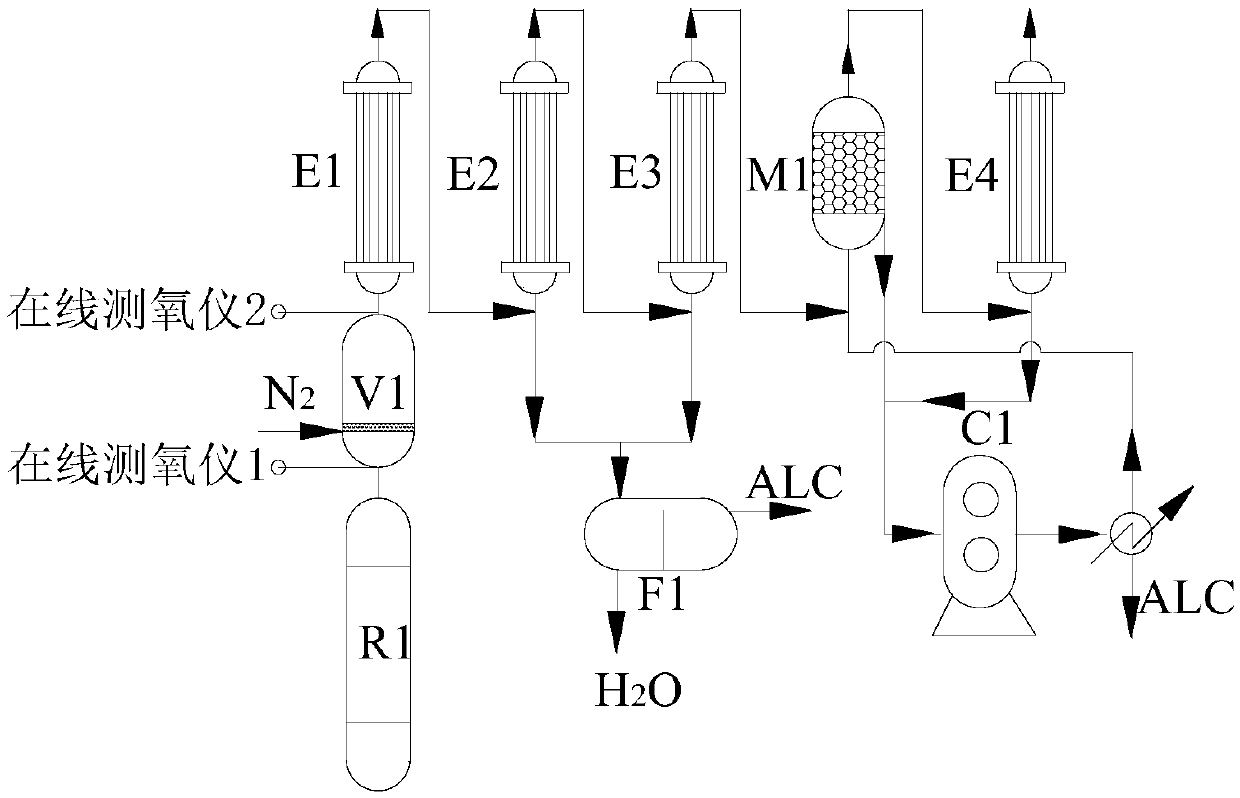

Image

Examples

Embodiment 1

[0038] Set the condensing temperature of the first-stage condenser (E1) to 7°C, the condensing temperature of the second-stage condenser (E2) to 1°C, the condensing temperature of the third-stage condenser (E3) to -5°C, and the condensing temperature of the fourth-stage condenser (E4) The temperature was -45°C.

[0039] The CN206304715U reactor is integrated with the processing device of a method for producing waste gas in the process of producing epichlorohydrin by the epoxidation of propylene chloride provided by this patent, and the reaction tail gas is sampled at the position of the online oxygen meter (1) and analyzed through laboratory tests. The content of allyl chloride is 93.2v%, the water vapor is 0.3v%, the oxygen content measured by the online oxygen meter (1) is 4.5v%, and the content of allyl chloride in the tail gas is outside the explosion limit range of allyl chloride (2.9v%~11.2v%) .

[0040]A gas distributor is installed at the connection between the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com