Fermentation post-treatment process for recombinant human interferon alpha2b

A technology for recombinant human interferon and treatment process, which is applied in the field of post-fermentation treatment process of recombinant human interferon α2b, can solve the problems of difficult production process and high purification cost, achieve high production efficiency, reduce protein adsorption, and eliminate fermentation problems fluctuating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

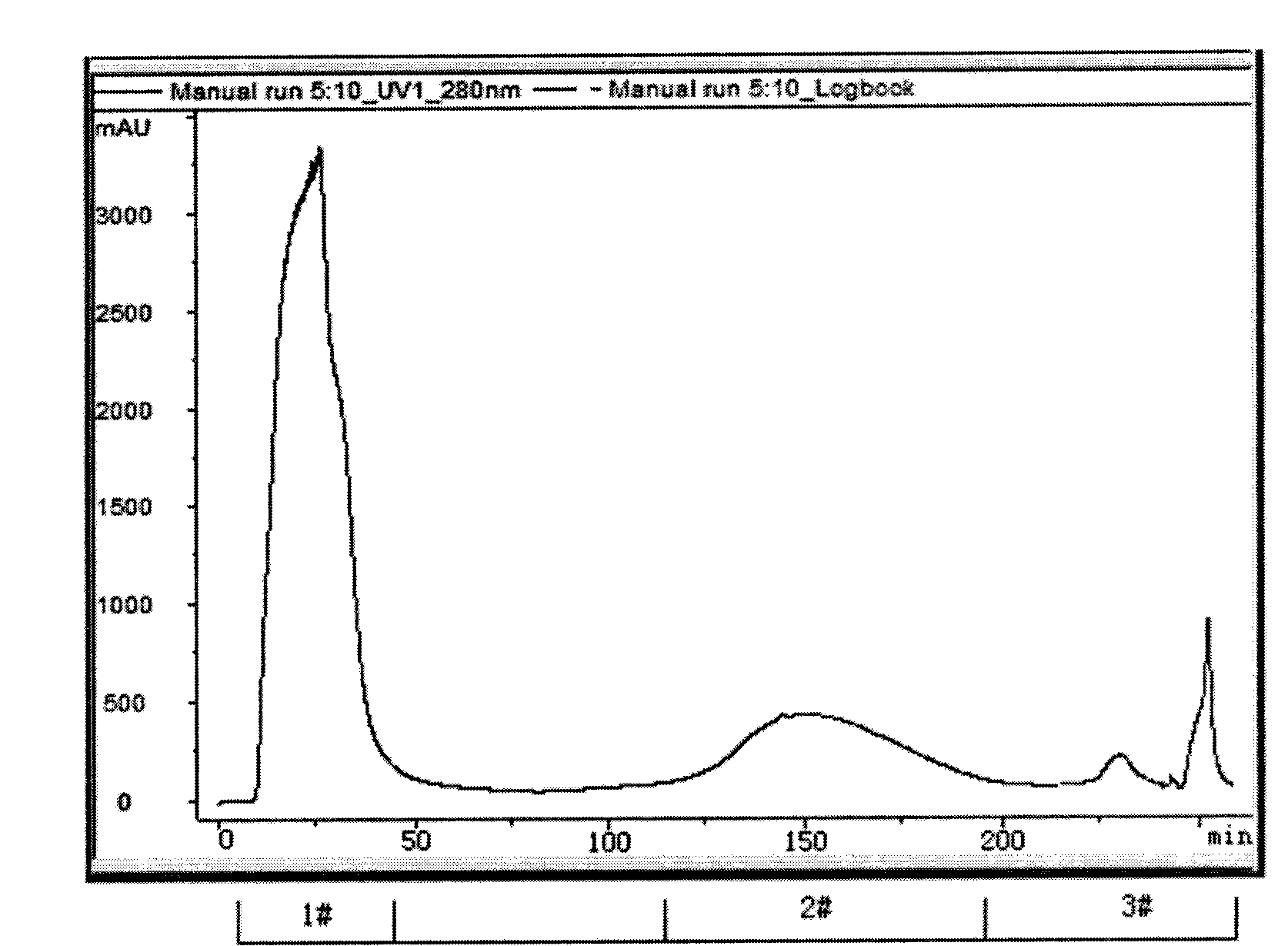

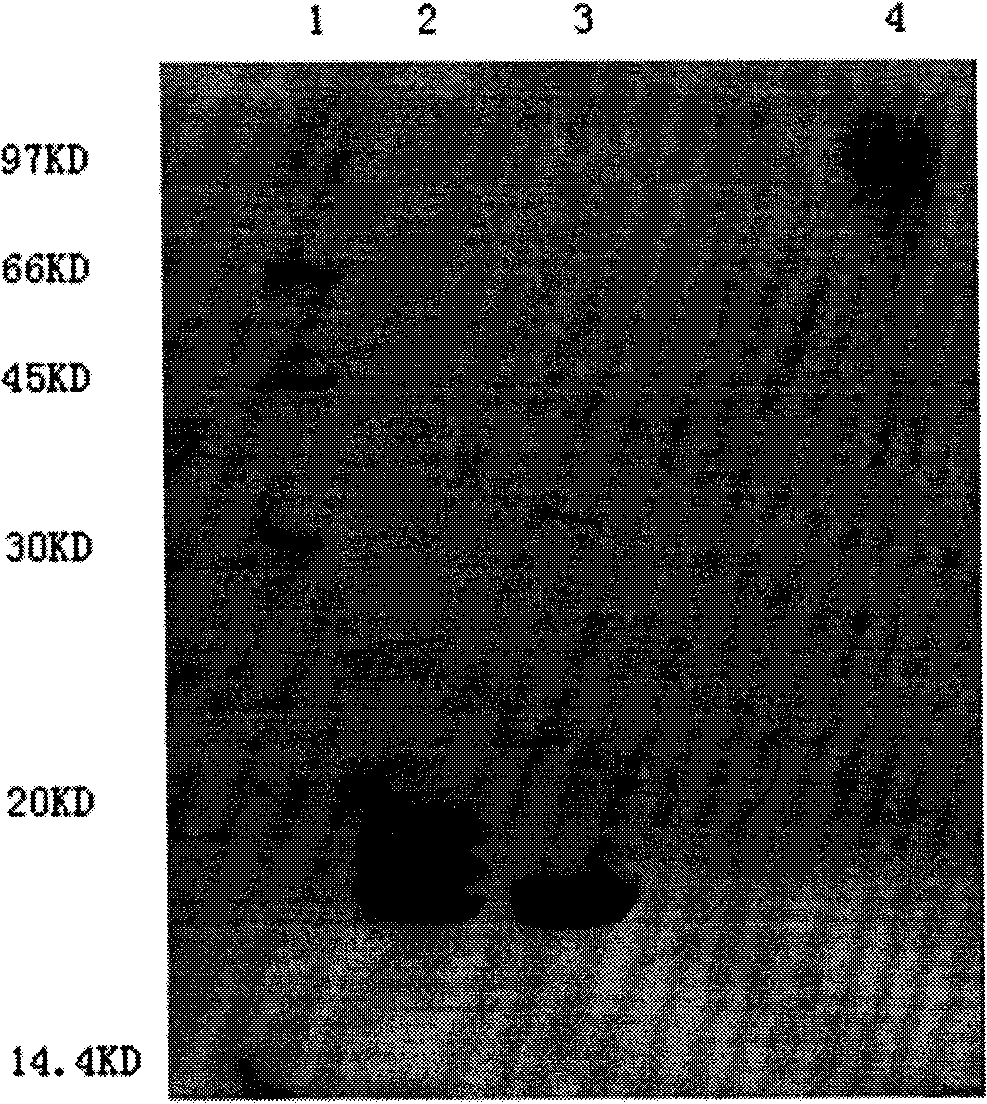

[0028] 1) Removal of recombinant human interferon α2b yeast fermentation liquid cells

[0029] The fermentation broth of recombinant human interferon α2b was taken, and the mode of continuous feeding was adopted, and 20mM Tris, 0.5% Vc, 10mM EDTA, 0.03% Tween80 buffer solution with a pH value of 6.3 were continuously fed, and a 0.45um hollow fiber microfiltration membrane tube was used. Microfiltration replaced 20 times. The flow rate of feed liquid is 1m / s, the operating pressure is 0.4MPa, the temperature is 10-20℃, and the flux of microfiltration is 2.5L / m 2 h.

[0030] 2) Concentration of target protein and replacement of buffer

[0031]Take the fermentation supernatant after microfiltration, add 20mM PBNa with a pH value of 6.5, 0.5% Vc, and 0.05% Tween80 buffer in a half-diluted manner, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com