Composite dephosphorization filter material

A composite, dephosphorization technology, applied in water treatment parameter control, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution, low treatment efficiency and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This composite dephosphorization filter material includes two components, the first one: volcanic rock, particle size: 1-2㎝; the second one: porous special dephosphorization filter material (a by-product of building aerated blocks), particle size: 1.5 -3.0cm, porosity: 40-50%, bulk density: 0.7-0.95g / cm 3 , The main components of the filter material: 71.5wt% fly ash, 4.5wt% cement, 18.9wt% quicklime, 5.1wt% gypsum; filter material production process: 200 ℃ high-temperature steam heating and inflating to form holes, and crushing into granules after forming.

Embodiment 2

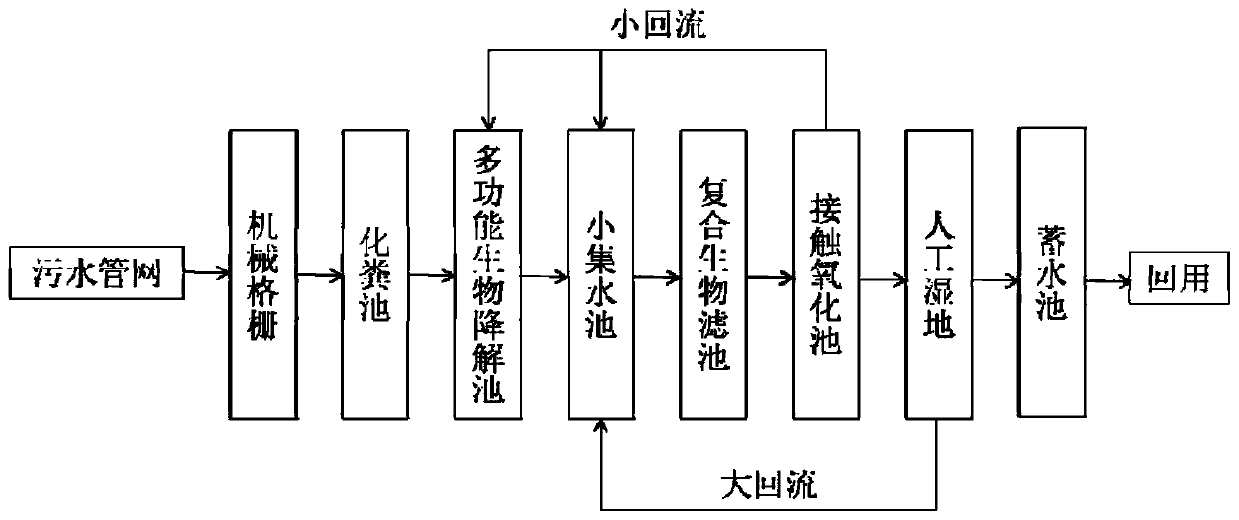

[0032] Utilize the compound dephosphorization filter material of embodiment 1 to carry out dephosphorization treatment to artificial wetland, treatment place is in Dalate banner photovoltaic base, treatment system such as figure 1 As shown, the composite biological filter adopts the pulse type multi-point sewage distributor disclosed in CN201821351534.9 for water distribution, and the constructed wetland adopts the greenhouse alternately interchangeable constructed wetland disclosed in CN201821190937.X.

[0033] Main process:

[0034] 1. After the sewage is collected through the pipeline, it enters the water collection well at the end of the pipeline, and then passes through the mechanical grille to remove the floating and suspended solids from the water to protect the normal operation of the water pump.

[0035] 2. After the grid treatment, the sewage enters the septic tank for preliminary degradation, and is lifted by the filter lifting pump into the multifunctional biodegra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com