Recyclable honeycomb tobacco lamina box

A technology of honeycomb sheets and smoke boxes is applied in the field of tobacco storage equipment, which can solve the problems of unevenness, damage, strength damage, etc., and achieve the effects of reducing the degree of structural damage, realizing recycling and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

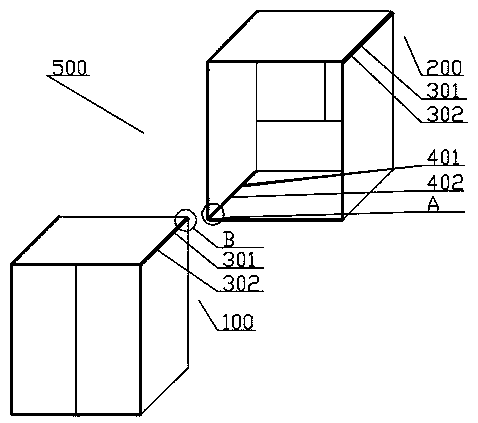

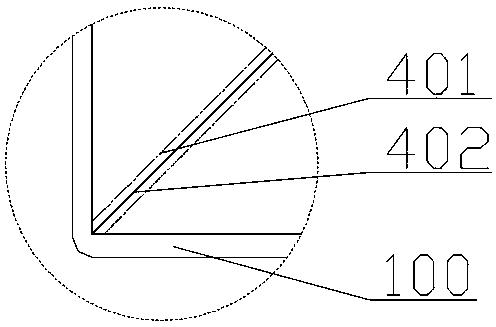

[0037] refer to Figure 1~6 , a recyclable honeycomb sheet smoke box 500 of the present embodiment includes an inner box 100 and an outer box 200, the inner box 100 and the outer box 200 are all composed of a bottom surface and side walls that are closed and connected. The two side panels bent at 90° are spliced together, and the bending part of the side wall is provided with two outer indentations on the outer side of the inner box 100 / outer box 200, and two outer indentations on the inner box 100 / outer box 200 There is one inner indentation 402 on the inner surface of the bend, and the outer and inner indentations 402 are alternately distributed.

[0038] The bottom surface of the inner box 100 and the outer box 200 is a combined detachable structure formed by sequentially covering the first bottom surface connected with two side panels respectively, or an integral detachable structure connected with the side panel bottom. , the bottom surface and the closed shape of the ...

Embodiment 2

[0050] Compared with embodiment 1, a kind of recyclable honeycomb sheet smoke box of the present embodiment has the following differences:

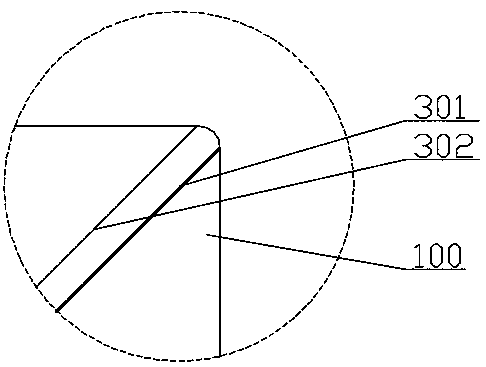

[0051] refer to Figure 7~10 , the recyclable honeycomb sheet smoke box in this embodiment, the outer indentations located on the outer side of the inner box 100 / outer box 200 bend include the first outer indentation 301 and the second outer indentation 302, a total of 2 outer indentations; The inner indentations on the bent inner surface of the box 100 / outer box 200 include the first inner indentation 402, the second inner indentation 403, and the third inner indentation 404, a total of three inner indentations; the first inner indentation 402 is the second inner indentation. Between the inner indentation 403 and the third inner indentation 404, the depth of the first inner indentation 402 is 1 / 2 of the thickness of the honeycomb cardboard used for the honeycomb sheet smoke box, that is, 4mm, and the depth of the second inner indentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com