Micro-stirring friction welding process for electronic packaging

A friction welding and electronic packaging technology, which is applied in welding equipment, non-electric welding equipment, metal processing, etc., can solve the problems of high density and pollution-free effect, and achieve good application prospects, short time consumption, and smooth welding process. The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

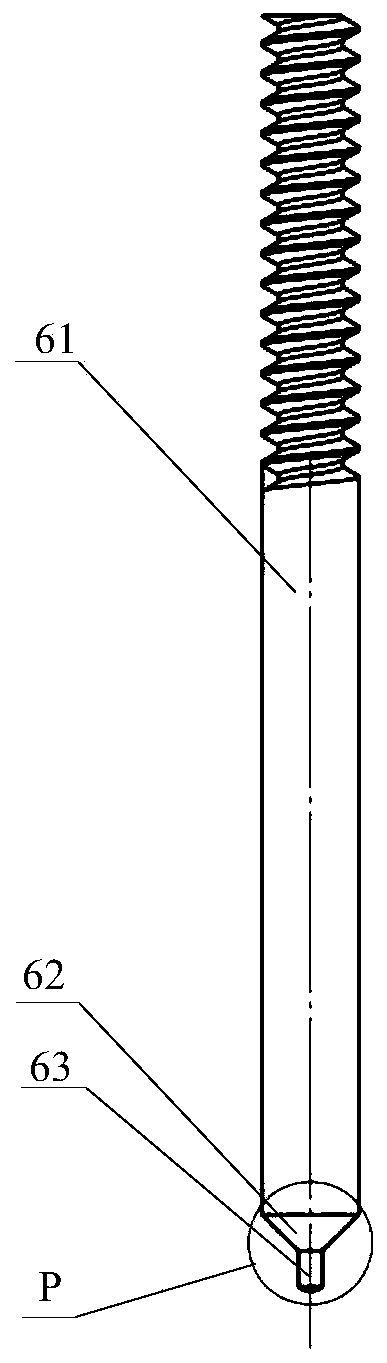

[0024] Specific implementation mode one: combine Figure 1-6 Describe this embodiment, a micro-stir friction welding process for electronic packaging. First, the first pad 1 and the second pad 2 to be welded are a group of pads. When the pads are arranged in a single point , the press-in hole 4 is prefabricated on the first substrate 3, and the pad group is arranged in parallel between the first substrate 3 and the second substrate 5, and the center position of the press-in hole 4 is aligned with the pad group Arrange in the center, then use the clamp to press the first substrate 3 and the second substrate 5, align the stirring head 6 coaxially above the pressing hole 4, control the stirring head 6 to rotate at a high speed and move down into the pressing hole 4, Then press it into the first pad 1, and realize the permanent metallurgical connection between the first pad 1 and the second pad 2 under the set press-in amount and holding time, and finally control the stirring head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com