A hazardous solid waste recycling pretreatment device

A pretreatment device, a technology for hazardous solids, which is applied in the field of hazardous waste and can solve the problems of relying on manual processing and lack of hazardous solid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

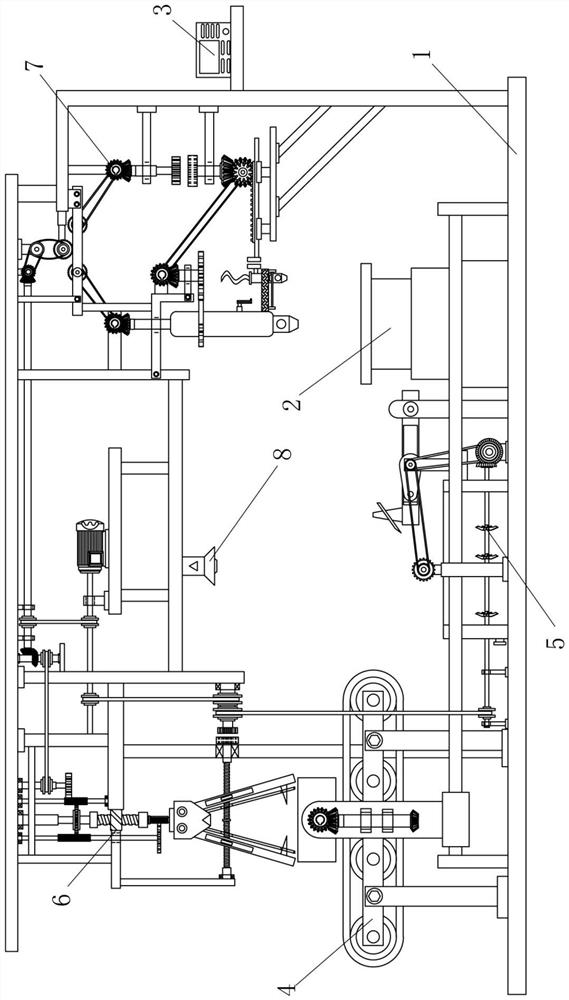

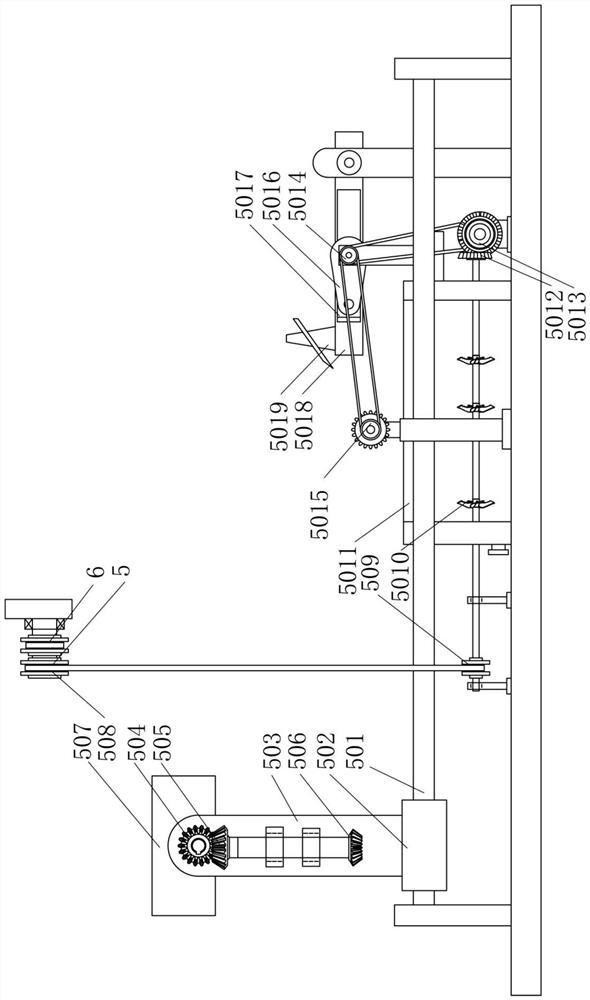

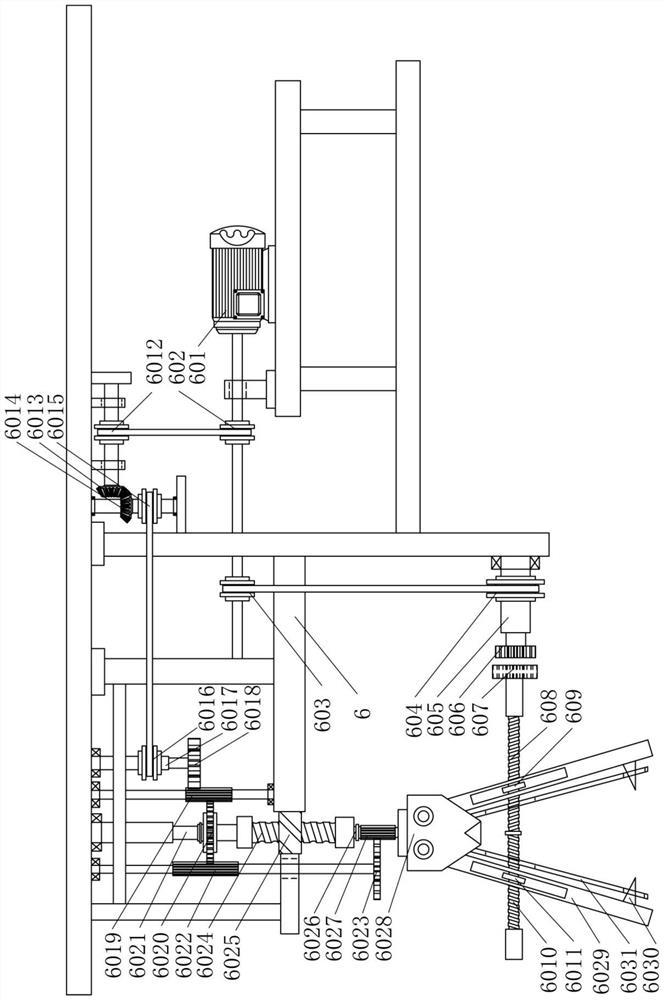

[0031] A hazardous solid waste recovery pretreatment device, such as Figure 1-9 As shown, it includes an outer frame 1, a lifting table 2, a control panel 3, a conveyor belt 4, a flipping and breaking cleaning device 5, a plugging device 6, a wax sealing device 7, and a water mist nozzle 8; the right side of the inner bottom of the outer frame 1 and the lifting The platform 2 is connected; the outer frame 1 is provided with a control panel 3 on the upper right side; the left side of the inner bottom of the outer frame 1 is connected with the conveyor belt 4; The left side of the inner top is provided with an unplugging device 6, and the right side of the bottom end of the unplugging device 6 is connected with the turning and breaking cleaning device 5; The top is connected with the unplugging device 6; a water mist nozzle 8 is arranged above the flipping breaking cleaning device 5.

[0032] Working principle: When in use, first install the hazardous solid waste recovery pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com