Low-sugar low-fat oat powder adopting biological activity fermentation

A biologically active, oat flour technology, applied in the field of food processing, can solve problems such as rising blood sugar levels, and achieve the effects of lowering blood sugar levels, increasing density, and being easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of fermented oatmeal powder is as follows, between raw material by mass ratio:

[0022] (1) Mix 75~85 parts of naked oat grains and 5~10 parts of oat bran at 90 o C~100 o Cook at C for 20~35min, take out and cool, then put naked oats in 85 o C~90 o Cook at C for 5~15min, take out and dry;

[0023] (2) Put the naked oat grains and oat bran after cooking and drying in step (1) into a pulverizer respectively, and pulverize them to 400um~550um to obtain oat flour and oat bran powder;

[0024] (3) Add 0.3~0.6 parts of amylase to natural oat flour, at 35 o C~45 o Carry out enzymatic hydrolysis treatment at C temperature, control the pH value of the enzymatic hydrolysis to 6.2~7.5, and the enzymatic hydrolysis time is 5~7h;

[0025] (4) Add oat bran powder, 3-5 parts of maltose, 6.7-9.4 parts of wolfberry powder and soybean powder to the oat flour after enzymatic hydrolysis in step (3), and after high-temperature sterilization and drying, it become...

Embodiment 2

[0027] The preparation method of fermented oatmeal powder is as follows, between raw material by mass ratio:

[0028] (1) Mix 75~85 parts of naked oat grains and 5~10 parts of oat bran at 90 o C~100 o Cook at C for 20~35min, take out and cool, put naked oats in 90 o C~100 o Cook at C for 5~15min, take out and dry;

[0029] (2) Put the naked oat grains and oat bran after cooking and drying in step (1) into a pulverizer respectively, and pulverize them to 400um~550um to obtain oat flour and oat bran powder;

[0030] (3) Add 0.3~0.6 parts of amylase to oat flour, at 35 o C~45 o Carry out enzymatic hydrolysis treatment at C temperature, control the pH value of the enzymatic hydrolysis to 6.2~7.5, and the enzymatic hydrolysis time is 5~7h;

[0031] (4) Add oat bran powder, 3-5 parts of maltose, 6.7-9.4 parts of wolfberry powder and soybean powder to the oat flour after enzymatic hydrolysis in step (3), and after high-temperature sterilization and drying, it becomes low-sugar ...

Embodiment 3

[0033] The preparation method of fermented oatmeal powder is as follows, between raw material by mass ratio:

[0034] (1) Mix 75~85 parts of naked oat grains and 5~10 parts of oat bran at 90 o C~100 o Cook at C for 20~35min, take out and dry;

[0035] (2) Put the naked oat grains and oat bran after cooking and drying in step (1) into a pulverizer respectively, and pulverize them to 400um~550um to obtain oat flour and oat bran powder;

[0036] (3) Add 0.3~0.6 parts of amylase to oat flour, at 35 o C~45 o Carry out enzymatic hydrolysis treatment at C temperature, control the pH value of the enzymatic hydrolysis to 6.2~7.5, and the enzymatic hydrolysis time is 5~7h;

[0037] (4) Add oat bran powder, 3-5 parts of maltose, 6.7-9.4 parts of wolfberry powder and soybean powder to the oat flour after enzymatic hydrolysis in step (3), and oat flour is obtained after high-temperature sterilization and drying.

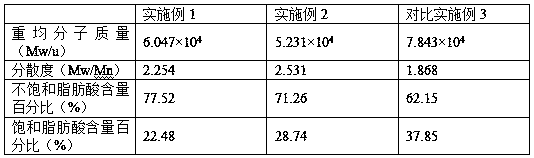

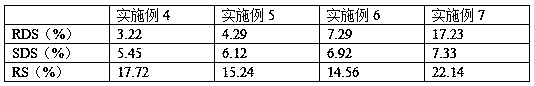

[0038] Table 1. Nutrient content of oat flour in Examples 1 to 3

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com