Chip precision film resistor array and manufacturing method thereof

A manufacturing method and precise technology, applied in the direction of resistance manufacturing, thin-film resistors, and resistors manufactured by photolithography, etc., can solve the problem that the inner wall of the through-hole of the exclusion substrate cannot be effectively covered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

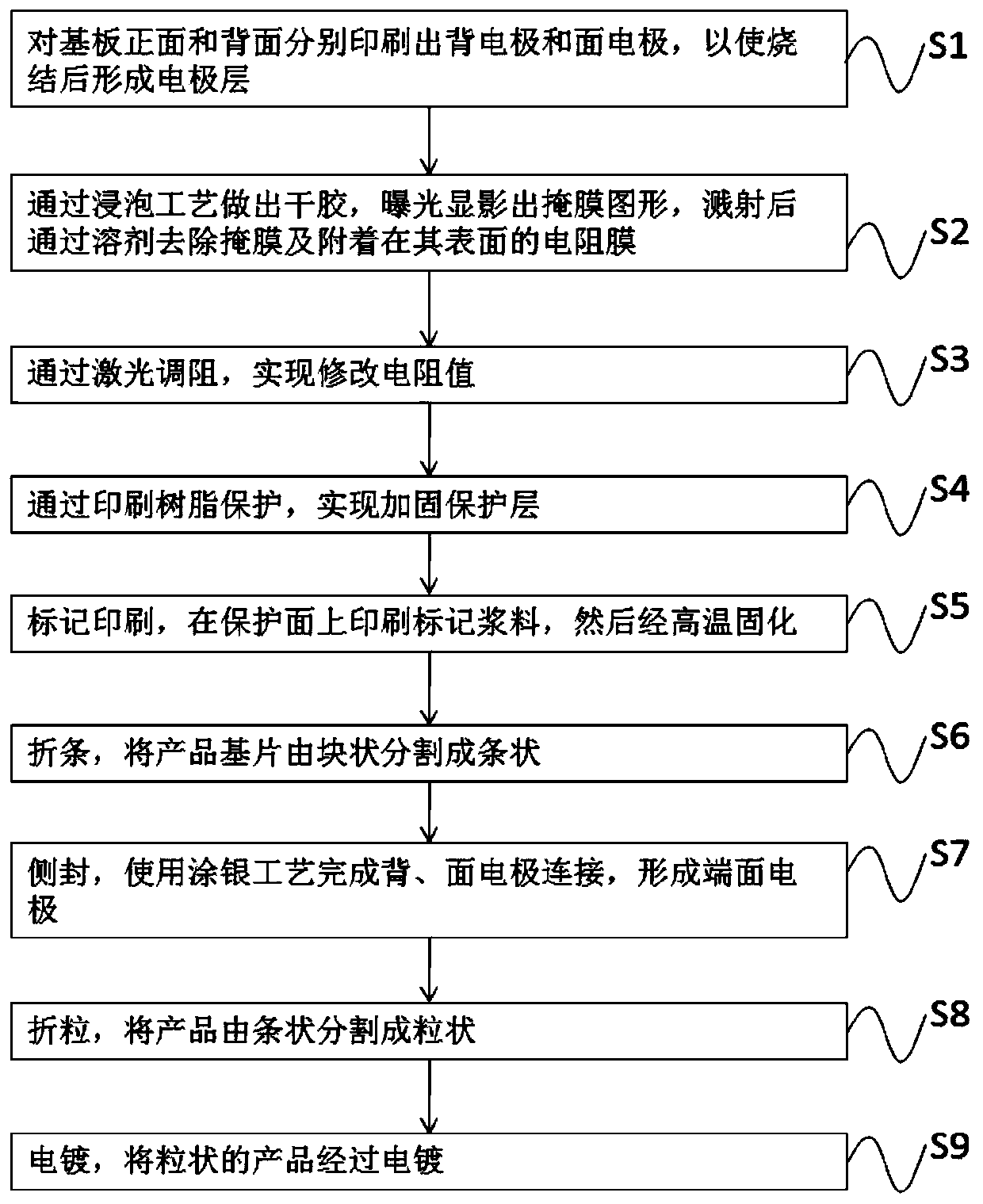

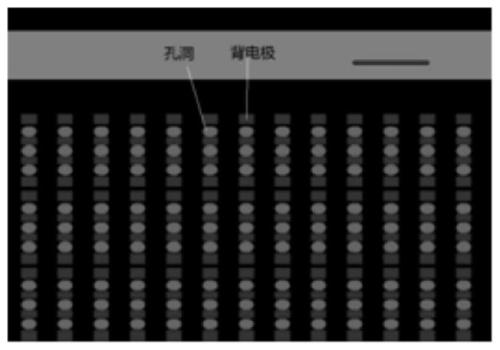

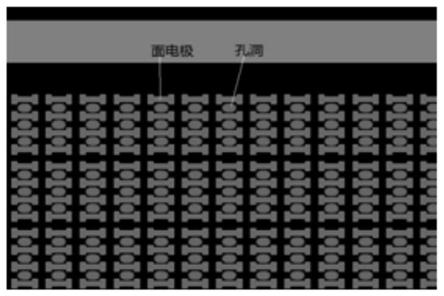

[0064] Please refer to Figure 7-Figure 8 , The specification model is 4R03, the target resistance is 10KΩ, the resistance precision control: ±0.5%, TCR: ±25ppm / ℃; it adopts alumina ceramic substrate.

[0065] The production process is as follows:

[0066] Step 1: Print the back and surface electrodes by printing, and form the electrode layer after sintering.

[0067] Step 2: Soak dry glue:

[0068] ① Put the product into the photoresist (phenolic resin) liquid, the thickness of the liquid film is 1.0 μm to 4.5 μm, the product moves up and down during soaking, so that the colloid completely covers the product hole, and the soaking time is 10 to 15 minutes.

[0069] ② After the colloid is covered, put the product in a drying oven and dry it at 100-150°C for 10 minutes. Obtain solid dry glue.

[0070] ③. Expose and develop the mask pattern, and after sputtering, remove the mask layer with a release agent to expose the resistor.

[0071] Step 3: Laser adjustment of resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com