Boiler chimney smoke discharge auxiliary heating white smoke elimination device and method

A chimney smoke removal and whitening technology, applied in combustion methods, indirect carbon dioxide emission reduction, lighting and heating equipment, etc., can solve problems such as insufficient utilization of slag waste heat, damage to boiler room structure corrosion, and impact on boiler thermal efficiency, etc., to achieve Avoid secondary pollution of dust, reduce dosage, and ensure cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

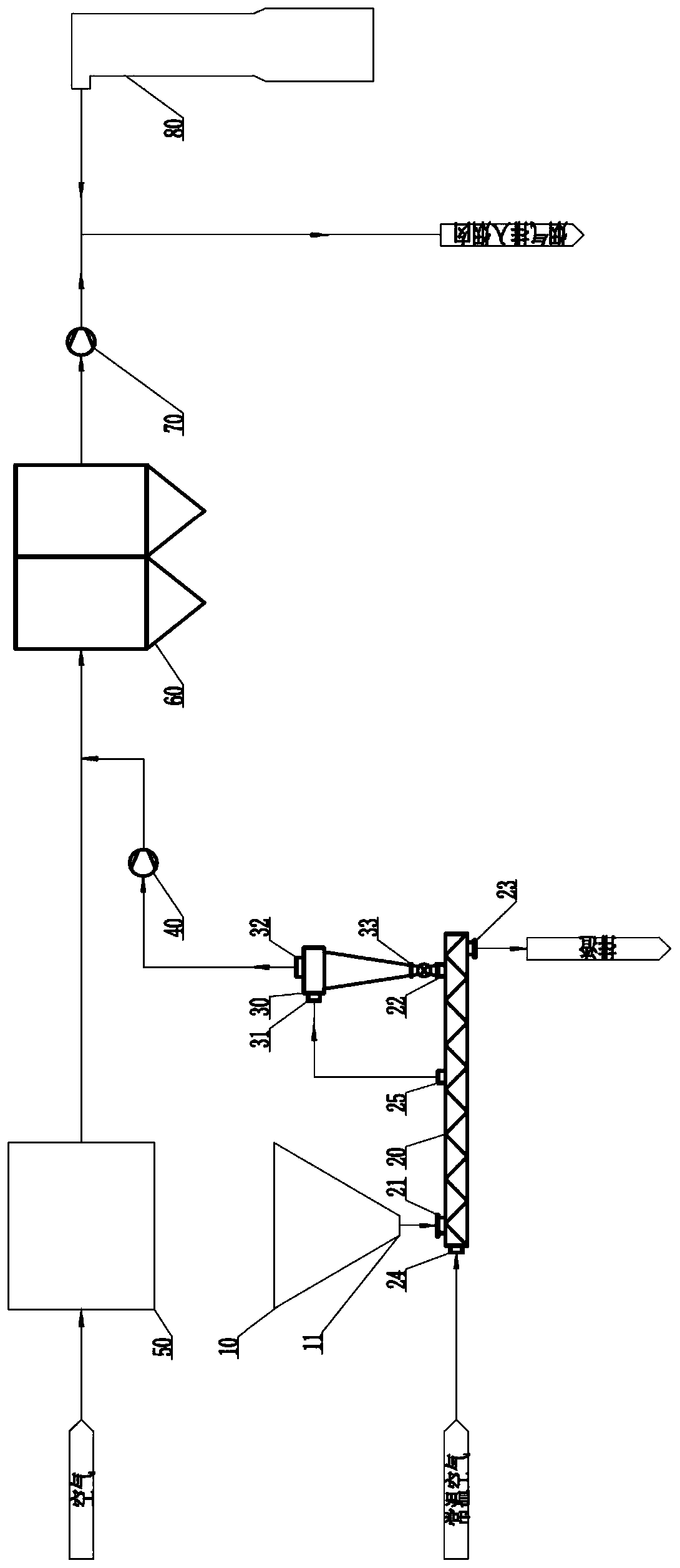

[0043] According to the first aspect of the present invention, such as figure 1 As shown, the present invention provides an auxiliary heating and whitening device for boiler chimney exhaust, which includes a boiler slag hopper 10 , an air-cooled slag cooler 20 , a cyclone separator 30 , an air preheater 50 and a dust collector 60 .

[0044] Specifically, as figure 2 As shown, the air-cooled slag cooler 20 is respectively provided with a slag input port 21 , a gas input port 24 , a gas output port 25 , a slag inlet port 22 and a slag outlet port 23 .

[0045] Wherein, the boiler slag hopper outlet 11 at the lower end of the boiler slag hopper 10 is connected to the slag input port 21 of the air-cooled slag cooler 20 . The slag produced by boiler combustion enters the air-cooled slag cooler 20 through the slag input port 21 , and the air at normal temperature enters the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com